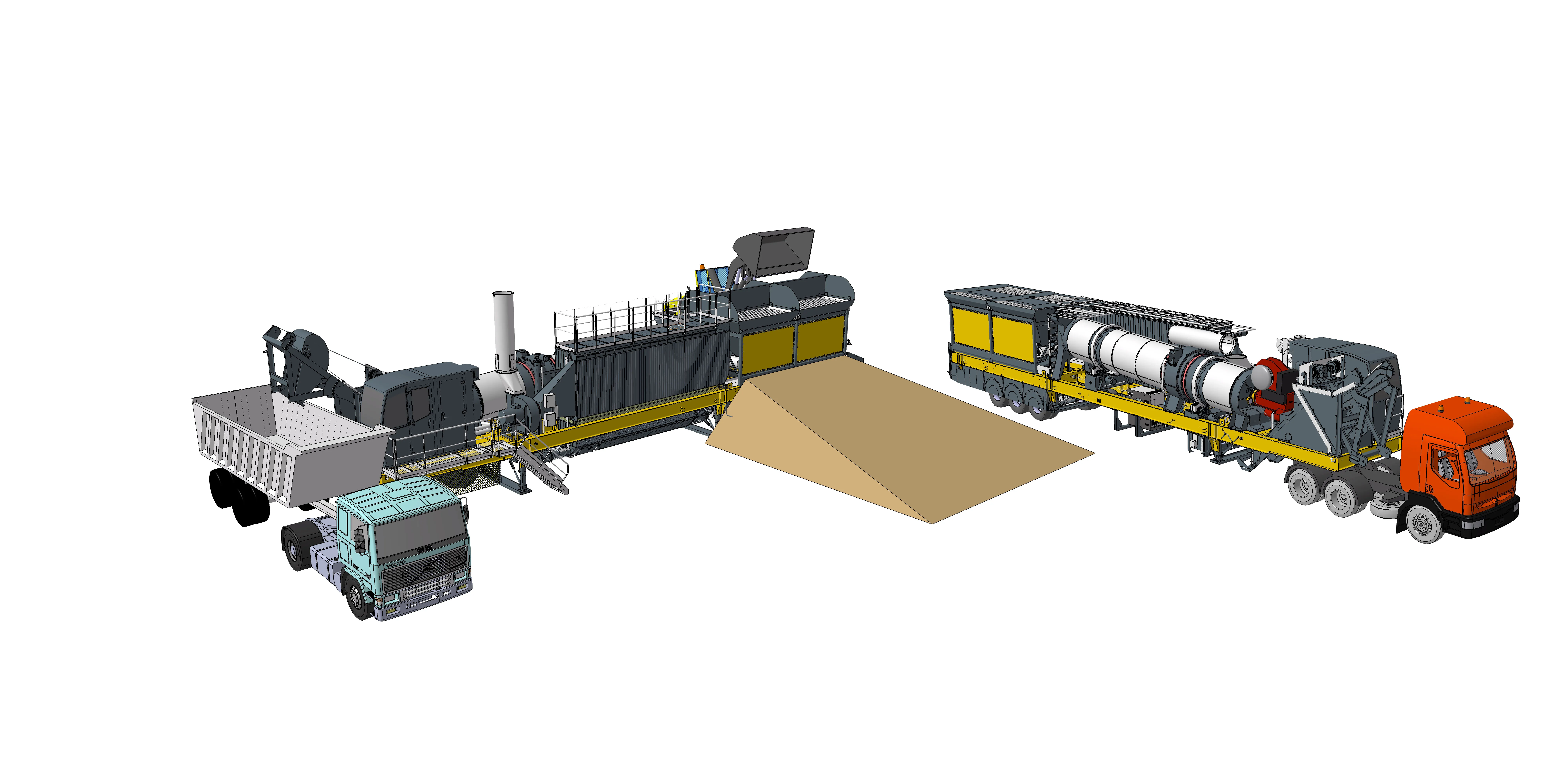

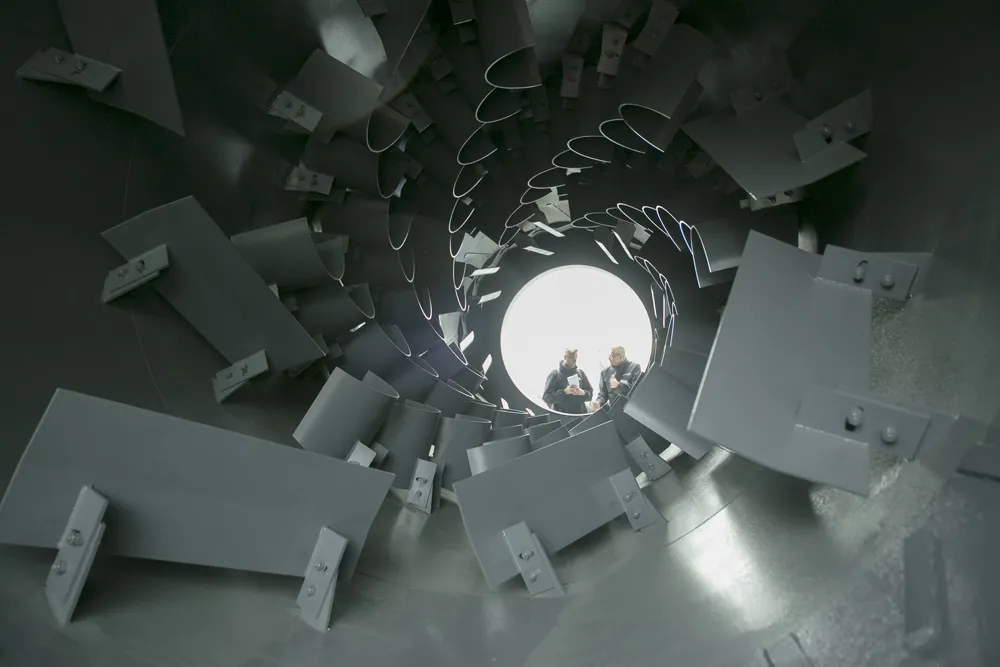

Ermont says it is now seeing strong interest for its novel TSX continuous asphalt plant technology, which is available in both stationary and highway portable versions. The design features a single drum and a single burner but is able to deliver a mix containing a high percentage of recycled material. Romain Thommerot, marketing and communications officer for the firm commented, “We have a RAP capacity of 70%.”

The stationary technology can deliver more varieties of product for the customer such as clear binders, semi warm asphalt and even cold mix. However, the portable plants are also versatile by their very nature. The design of the TSX system allows for changes in the feed, while ensuring quality of the output remains constantly high. The firm is commissioning the first stationary plant using the technology in the second quarter of 2024. “We already have some TSX HIGHWAY plants commissioned.”

The TSX HIGHWAY models are available in three versions, the TSX23, TSX26 and TSX28. These offer outputs of 120-270tonnes/hour, 160-380tonnes/hour and 200-450tonnes/hour respectively. All three can use up to 70% RAP in the feed. The TSX stationary plants are available in the TSX23 INCITY, TSX26 INCITY and TSX28 INCITY variants, with the same outputs as the Highway versions.

In addition, the firm is also offering its TRX plant in INCITY stationary and HIGHWAY transportable versions. The former offers capacities from 150-360tonnes/hour and can use up to 80% RAP in the feed, while the latter offers capacities from 150-430tonnes/hour and can use up to 100% RAP in the feed.