The local Ministry of Transport recently introduced the "Quality in Road Construction in Baden-Württemberg 4.0" (QSBW 4.0), which will be standard by 2021. The objective of QSBW 4.0 is a digitally controlled construction process that ensures paving quality and increases road surface life.

Invitations to tender based on QSBW 4.0 criteria will require technology associated with a digitally controlled and monitored job site. This comprises dynamic logistics and machine control, quality control and management, mobile networking, display options on smartphones, tablets or computers as well as the documentation of all data with access authorisation for clients.

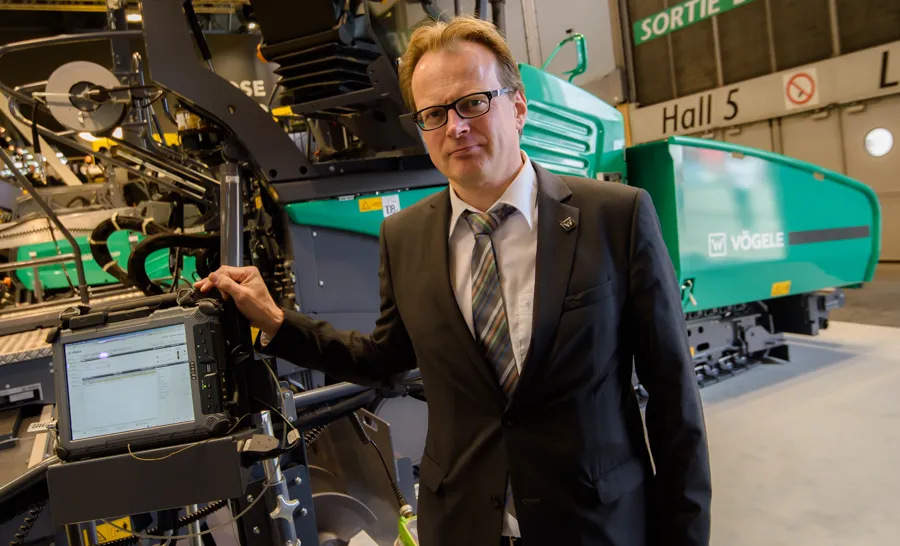

Some solutions exist already, with one coming from Vögele in the shape of its advanced WITOS Paving Plus package. This integrated, software-based overall system for process optimisation and documentation comprises five connected modules for the parties involved, from the asphalt mixing plant and the truck driver to the construction manager.

With WITOS Paving Plus, contractors can meet requirements for pavers that will be specified in future in invitations to tender under QSBW 4.0.

Temperature measurements are the focus of the quality control measures in QSBW 4.0. To ensure an optimum asphalt temperature, measurements are checked throughout the process. Meeting these requirements is easy with WITOS Paving Plus, since Vögele’s RoadScan temperature measurement solution can be integrated into the system. Using RoadScan, a high-precision infrared camera scans the specified area behind the screed of the paver, across a width of 10m.

In the project to rehabilitate a regional road, A Waggershauser Straßenbau was able to fulfil QSBW 4.0 by using the WITOS Paving Plus system. The QSBW 4.0 methodology was developed by the Ministry of Transport of Baden-Württemberg in collaboration with companies in the construction sector and summarised in a manual.