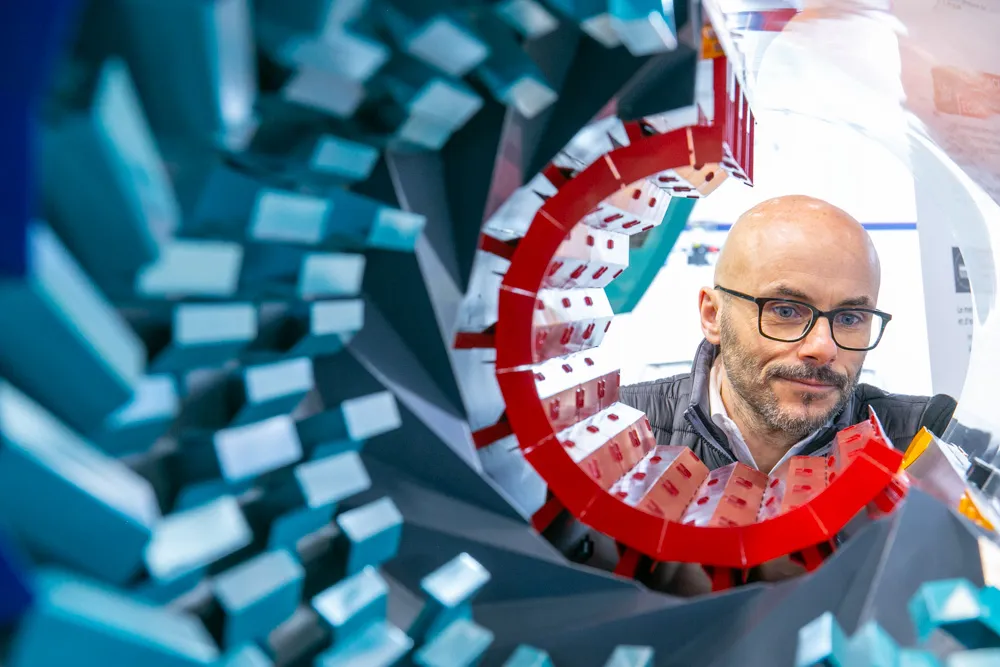

Reduced emissions represent a key development for Ammann's asphalt plant technology. The firm’s advanced VRD filtration system from Ammann is able to remove a significant level of emissions, as well as being self-cleaning.

“To have the performance and efficiency of VRD in a self-cleaning system is a significant benefit for businesses,” Marzio Ferrini said.

The patented technology means that there is no need for filter replacements and plant uptime is optimised. The modular VRD system is compatible with virtually every type of asphalt-mixing plant, including those from other manufacturers. The system reduces total organic carbon (TOC), which contains VOCs, by as much as 70% under working conditions.

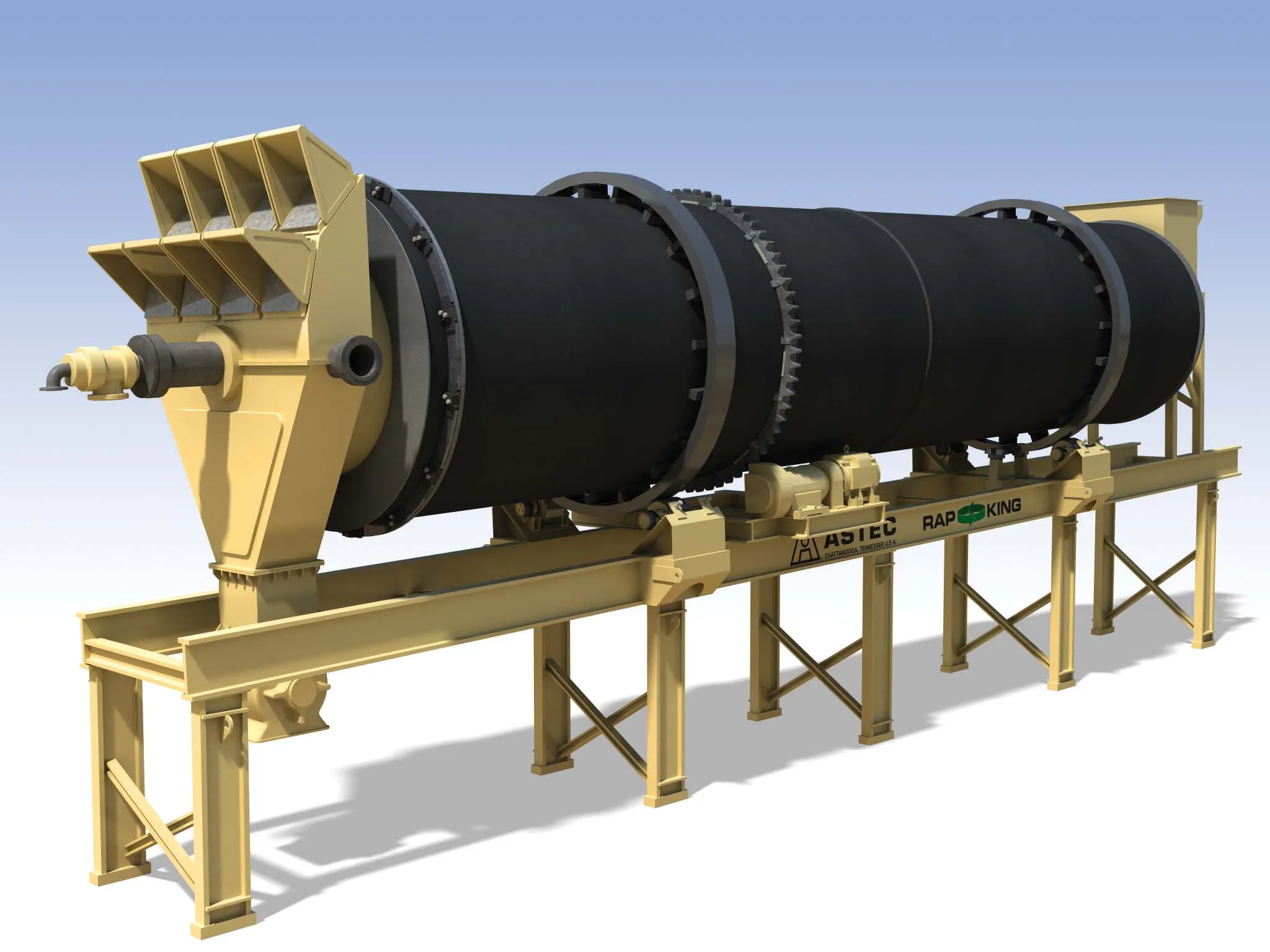

The VRD removes the TOC. In addition, it makes using RAP greener, as a high percentage of VOCs occur while recycling. The system only needs a power supply and on-site space for implementation and requires no special software or upgrades. It can be included in the purchase of a new plant and can be retrofitted to existing plants, while it is also easy to transport and install.

The VRD is a key component of the firm’s Green Plant Initiative, intended to improving the sustainability of asphalt production.