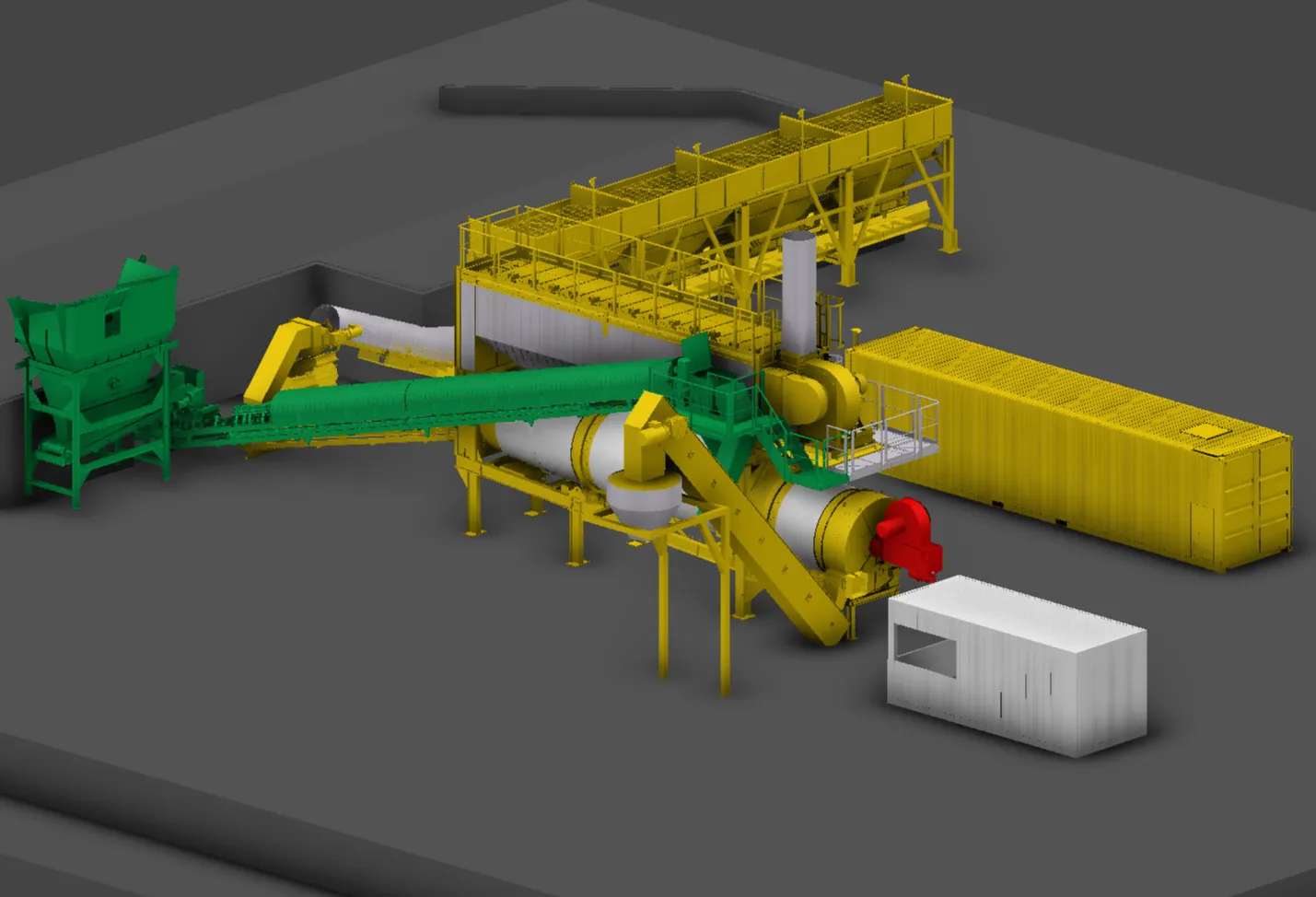

The plant, an ABA UniBatch, stands at a height of nearly 27m. It is a key product for Ammann as it enters the North American asphalt plant market.

“It’s one of the selected models we’re targeting for North America,” said Lieven Van Broekhoven, executive vice president of sales and marketing for Ammann, based in Switzerland.

Ammann chose to highlight UniBatch because of the plant’s ability to utilise high percentages of RAP. “Recycling is growing in importance in the US,” Van Broekhoven said. “It’s standard in Europe, but in the US it’s up and coming.”

UniBatch is billed as a technologically-advanced, fuel-efficient plant with a host of green benefits. It utilizes high percentages of recycled asphalt and includes a noise reduction system, a fumes extraction system, energy-saving software that further reduces emissions and full cladding that lessens dust and provides aesthetic appeal.

Van Broekhoven said the batch plant and its recycling capabilities will fill a niche in North America – and an important one at that.

“We’ll serve a niche segment, but I believe in that segment we have the best solution,” he said.