The firm used three pavers working in echelon for the large-scale project, which presented challenges in terms of both planning and precision. The firm used modern Volvo P7820D ABG pavers and also benefited from support of paving experts from Volvo CE.

The Wunstorf air base handles large transport aircraft in the shape of Airbus A400Ms as the Air Transport Wing 62 of the German armed forces (Bundeswehr) stationed at the military airfield, which is located north-west of Hanover.

Jörg Hebemeyer, road construction manager at Strabag's Hanover division explained that the firm had been rehabilitating the second runway in Wunstorf for over a year before the pavers could be used. Trucks carrying fresh asphalt had to drive up almost every minute once paving commenced so as to supply the three asphalt trains, each consisting of a road paver and a feeder. To complete the work, the teams were followed by rollers to finish the paving job.

With this setup, the firm was able to finish asphalting the entire runway within three days.

For Hebemeyer, who has been working at Strabag since 2018, it was a challenging project that demanded a lot from everyone involved. "In the end, we never had any problems with this project at any time.”

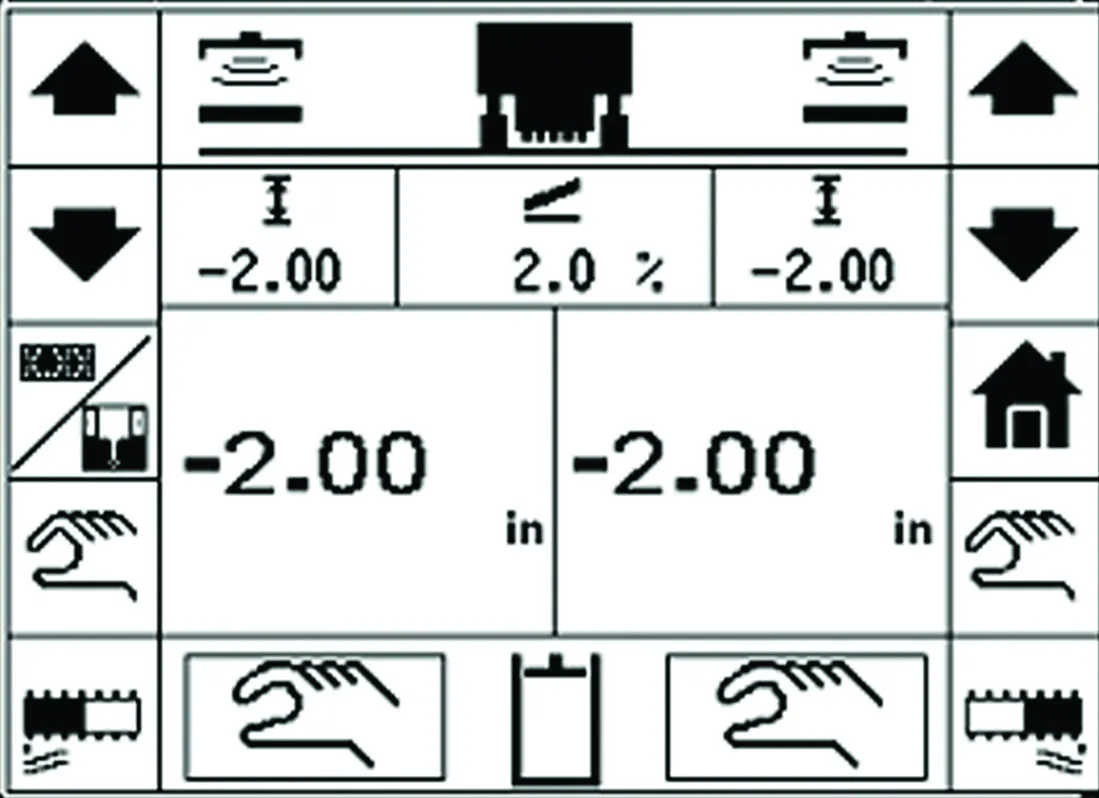

Michael Weinhold, one of the responsible paving foremen on site, commented that using the three pavers in echelon meant a paving width of 30m could be achieved.

Frank Dörrie, product manager Road Pavers at Volvo CE, and André Sebastian Meier, product manager Road Pavers & Rollers Germany, Austria, Switzerland, travelled to the site for the job. “You don't experience a project like this every day," said Dörrie.

Although the area was large, using three of the Volvo P6820D ABG pavers allowed Strabag to asphalt the entire runway in just one day.