Construction materials supplier Aggregate Industries recently completed major resurfacing work at Donington Park race circuit, just ahead of the British Superbike Championship in May.

Essential and extensive track maintenance work included the removal and replacement of more than 6,500 tonnes of asphalt completed over 22 days. It represents the most significant improvement at the venue in almost 20 years, according to Aggregate Industries.

Aggregate Industries worked with track-owners MotorSport Vision (MSV) and track designers Driven International as well as a complex supply chain. Provided were more than 5,000 tonnes of specially formulated high-grip SuperPrixmat Ultra asphalt, designed exclusively for demanding high-performance motor racing circuits. Aggregate Industries also provided 846 tonnes of binder course and 740 tonnes of stress-absorbing membrane interlayer, SuperSAMI.

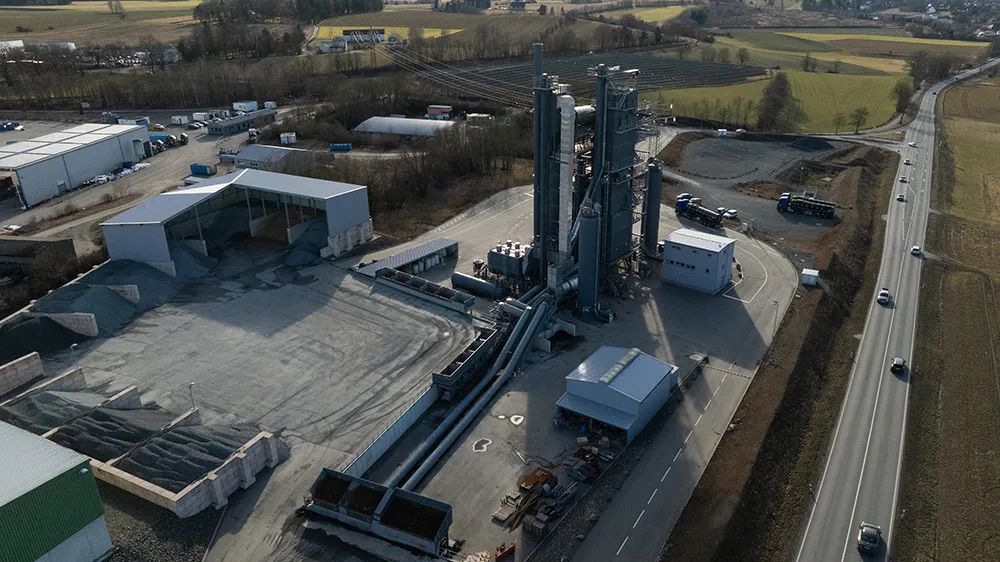

The time-intensive project required Aggregate Industries to use two supply plants to maximise time and minimise disruption on-site during the 22-days of construction. This allowed for a continuous supply of asphalt to the site, enabling the team to lay the product at a consistent speed in echelon to achieve a jointless surface on the 4km (2.5 mile) track.

Aggregate Industries said that following the work, race officials noted an overall improvement to performance levels and circuit grip during the British Superbike Championship, resulting in the fastest laps set to date.

“The resurfacing of any major project requires meticulous planning and a true collaborative approach across all involved contractors. The resurfacing of Donington Park was no different,” said Vicky Smith, regional director for surfacing solutions at Aggregate Industries.