Road building takes centre stage in the SaMoTer LAB demo area at the forthcoming equipment exhibition in Verona, Italy.

Machinery and technologies will be hard at work for all to see. The big names will be there: CGT Caterpillar, Cenati, Hitachi Construction Machinery, Kiwitron, Develon (formerly Doosan), Dynapac-Fayat Group, Incofin, Komatsu, Leica Geosystems, Spring Machine Control, Topcon Positioning and SITECH-Spektra.

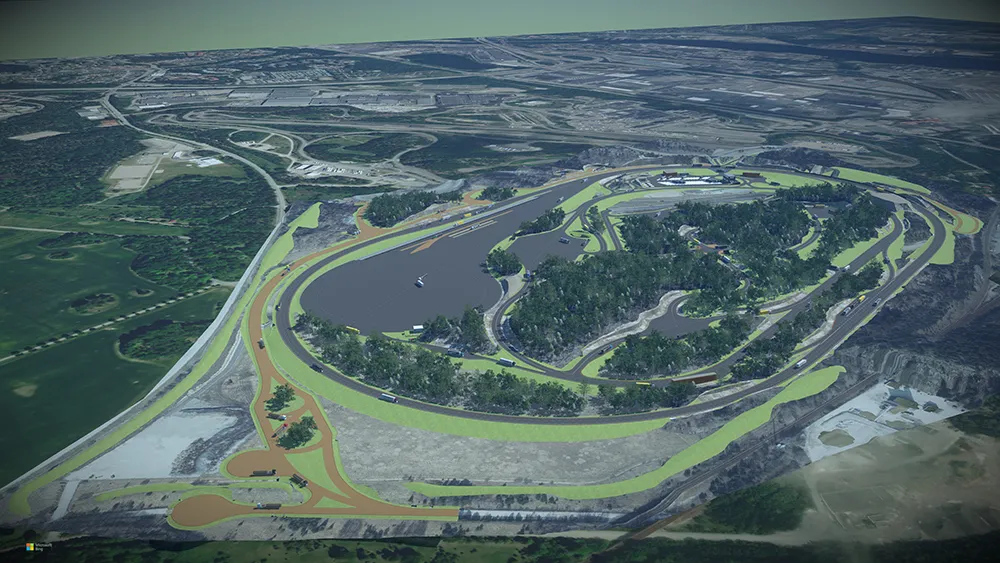

The new and revolutionary high-tech LAB demo will feature Cantiere Digitale - The Digital Construction Site. This is a full-scale automated construction site set up in collaboration with Quelli del Movimento Terra.

"SaMoTer Lab came about thanks to constant and continuous debate with the sector,” said Raul Barbieri, sales director of Veronafiere, the exhibition organiser. “This expressed the need for a venue specifically for technological displays, combined with updating, discussion and training opportunities. Samoter LAB consequently focuses on technological innovation, digitisation, de-carbonisation, safety and training. Cantiere Digitale - The Digital Construction Site is the natural outcome of all this, as a full-scale work place for cutting-edge machinery and technologies."

The Digital Construction Site will host typical construction site processes several times a day to highlight advantages in terms of productivity, quality and safety thanks to the use of these technologies.

Visitors attending SaMoTer will have the chance to watch 4.0 machinery and digital control technologies at work in the construction of road infrastructure across three strategic stages. There will be surveying with drones, GPS, scanners, mobile mapping and robotics. Design will be highlighted with the creation of a 3D project to ensure a flat and regular new road surface and start renovation work. Meanwhile, machine-to-machine interaction will be demonstrated.

SaMoTer is held alongside Asphaltica, the exhibition for road paving, safety and road infrastructure technologies and solutions. All this is promoted by and with SITEB-Strade Italiane & Bitumi.

For more information, please click on the SaMoter site.