Caterpillar is introducing a revised line-up of 20-24 tonne E Series crawler excavators at Intermat 2012. The 320E, 323E and the reduced radius 320E RR adopt the EU Stage IIIB Cat C6.6 ACERTTM engine, providing reduced emissions and fuel consumption savings of up to 11% compared to other D Series models. A wider range of cab seating, including heating and cooling options, comes with the new E Series crawler excavators. Time delay lighting, additional safety handrails and improved serviceability are also sai

April 11, 2012

Read time: 4 mins

The 320E, 323E and the reduced radius 320E RR adopt the EU Stage IIIB Cat C6.6 ACERTTM engine, providing reduced emissions and fuel consumption savings of up to 11% compared to other D Series models.

A wider range of cab seating, including heating and cooling options, comes with the new E Series crawler excavators. Time delay lighting, additional safety handrails and improved serviceability are also said make these mid-weight excavators an ideal choice for both contractors and rental companies. For customers involved in the earthmoving sector, Cat Grade Control Depth and Slope technology is available as factory-supplied option on all models, said to offer increased productivity and performance.

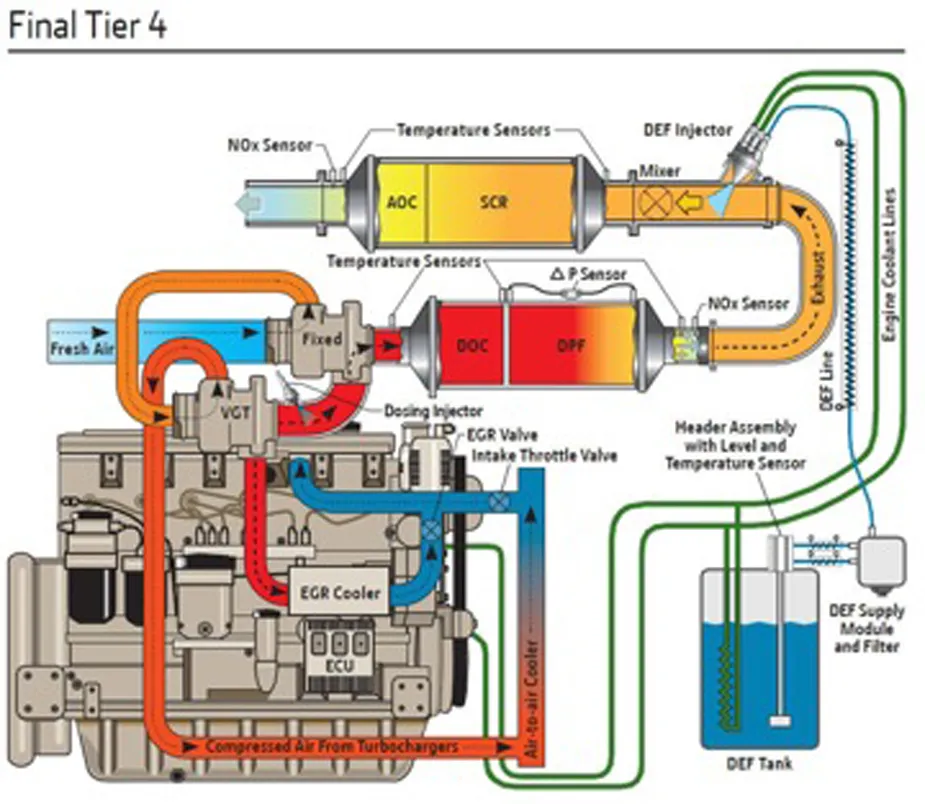

The two conventional bodied models, along with the reduced radius 320E RR, are powered by a Cat C6.6 ACERT diesel engine. Rated power is 152hp (112 kW for the two 320E models, and 165hp (121 kW) for the larger 323E. What is said to be a proven engine, the Cat C6.6 ACERT uses a suite of technologies, including the Cat Electronic Control Module (ECM) in combination with the Cat Clean Emission Module (CEM) to meet the EU Stage IIIB emissions standards. The CEM incorporates a Diesel Oxidation Catalyst (DOC) and a Diesel Particulate Filter (DPF), and a passive regeneration system that automatically cleans the DPF throughout the working cycle of the machine without requiring operator intervention or disruption to operations.

On the 320E and the 320E RR, the power management system provides two operating modes for the operator, high power mode and an economy mode. On the 323E, a third middle mode is offered. A fitted isochronous engine speed control is said by Caterpillar to ensure that the engine speed remains constant regardless of hydraulic demand. It is also said to reduce idle speed under no load, cutting fuel consumption further.

The three excavators feature an automatic engine idle shutdown system that will shut the engine down when it has been idling for more than a customer-specified amount of time. The idle period can be set between 1-60 minutes. In addition, an automatic engine speed control reduces engine revs by 100 rpm when the machine is not under load for more than five seconds, helping to save fuel and cut emissions.

The fuel system on the C6.6 ACERT is equipped with an electronically-controlled high pressure fuel injection system, featuring three-layer hoses, making it capable of running on bio-diesel up to a 20% mixture (EN 14214 or

E Series excavators use a twin-pump open-centre hydraulic system with what is said to be a highly efficient back-to-back main hydraulic valve.

In addition, the new E Series excavators have a clear LCD monitor that is 40% larger than the D Series model. With a higher resolution, this monitor is said to provide operators and technicians with vital operating and performance information. It is now programmable in 42 languages, up from 28 in the D Series machines.

The standard rear view camera displays its image through this cab monitor, which can handle up to three different camera feeds, displaying up to two camera views at any one time. Improved in-cab storage, a relocated coat hanger and automatic climate control are further improvements within the E Series cab.

The 320E RR is offered with a 5.7metre main boom and the R2.9B1 stick. Both the 320E and the 323E are available with a range of main boom and dipper sticks, to suit a variety of applications. The two machines can also be specified with a choice of Long or Long Narrow tracks and with hydraulic or electric tool control options. Caterpillar offers a wide range of work tools, along with general duty and severe duty buckets for all three machines. A quick coupler control is also available for the two conventional models.

Cat Grade Control Depth and Slope system can be factory-integrated to both the conventional and reduced radius excavators. The system is said to combine traditional machine control and guidance with factory-installed and calibrated components. Integrated with the in-cab monitor, Grade Control Depth and Slope reduces the need for traditional grade staking and checking, cutting time on site and further reducing fuel consumption.