Huesker said the restructure simplifies product selection and provides construction companies and transport engineers with single-source solutions for all application areas.

The company said that all Basetrac products offer interaction flexibility, high reliability and cost-effectiveness with straightforward installation. They are used as base reinforcement for permanent and temporary traffic areas, working platforms and railway applications.

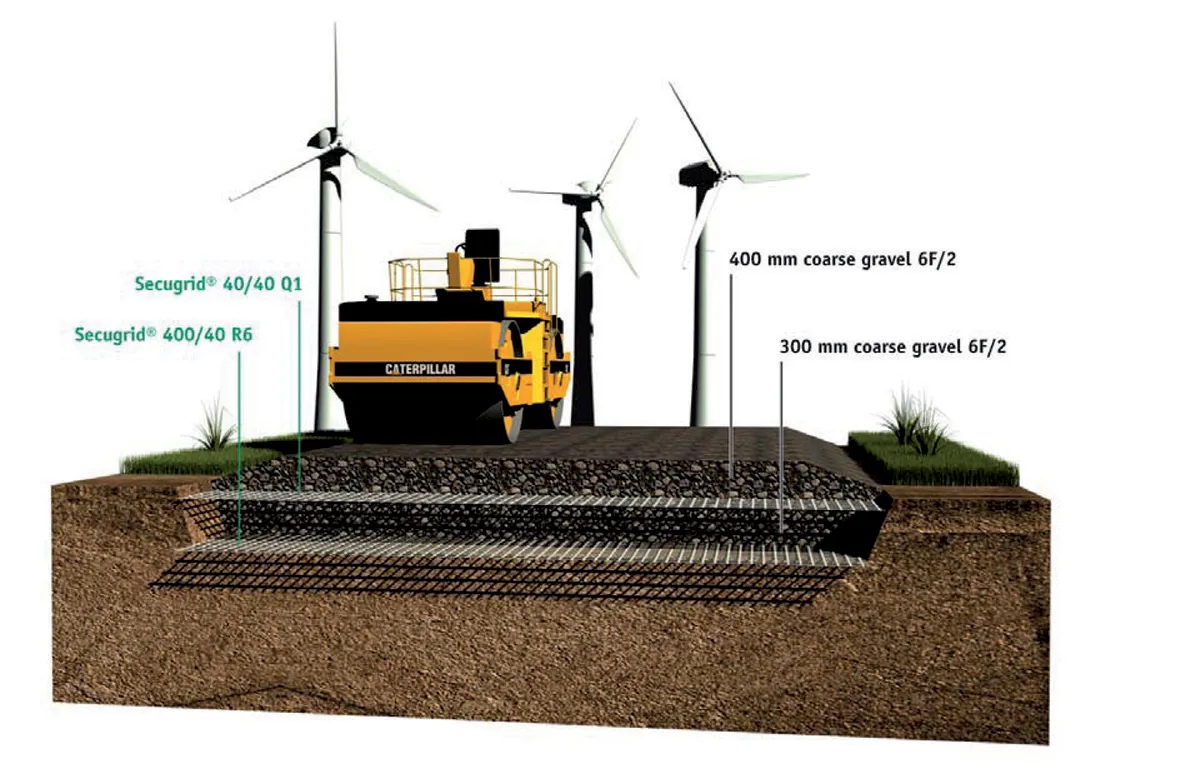

Traffic areas are permanently subject to heavy and fluctuating loads. Allowance must therefore be made, in the base course design, for the particularities of each application. Geosynethics have offered a tried-and-tested base course reinforcement solution for many years. They perform a key function by increasing bearing capacity and improving traffickability.

Further benefits include their high resistance to mechanical loads, straightforward installation, cost-effectiveness and eco-efficiency compared to conventional construction methods. As a result, the use of geosynthetics reduces the base course thickness and increases service life while significantly reducing maintenance intervals and costs.

The restructure move comes as Huesker introduces its BaseCalculator web application to calculate the base course thickness and select the most suitable product to match the condition of the soil and application type. The BaseCalculator is available free online.