The Dutch city of The Hague officially opens the Victory Boogie Woogie Tunnel today after more than five years of construction.

The twin-bore tunnel is part of the new 4km Rotterdamsebaan which runs from the Ypenburg junction (A4 and A13) to the Binckhorst Business Park near the centre of The Hague.

BAM Infra Nederland has been main contractor for the Rotterdamsebaan project at a cost of around €301 million. Work started in 2015 and includes two 450m-long ramps and 650m of cut and cover for the tunnel.

The tunnel, with a speed limit of 70km/h, is claimed to be the most sustainable tunnel in the Netherlands. Solar panels adorn the entrances and a fine particle dust reduction system manages the air inside the tunnel. Sustainable low-energy asphalt concrete - or LEAB asphalt after its Dutch acronym - has been used for road surfaces.

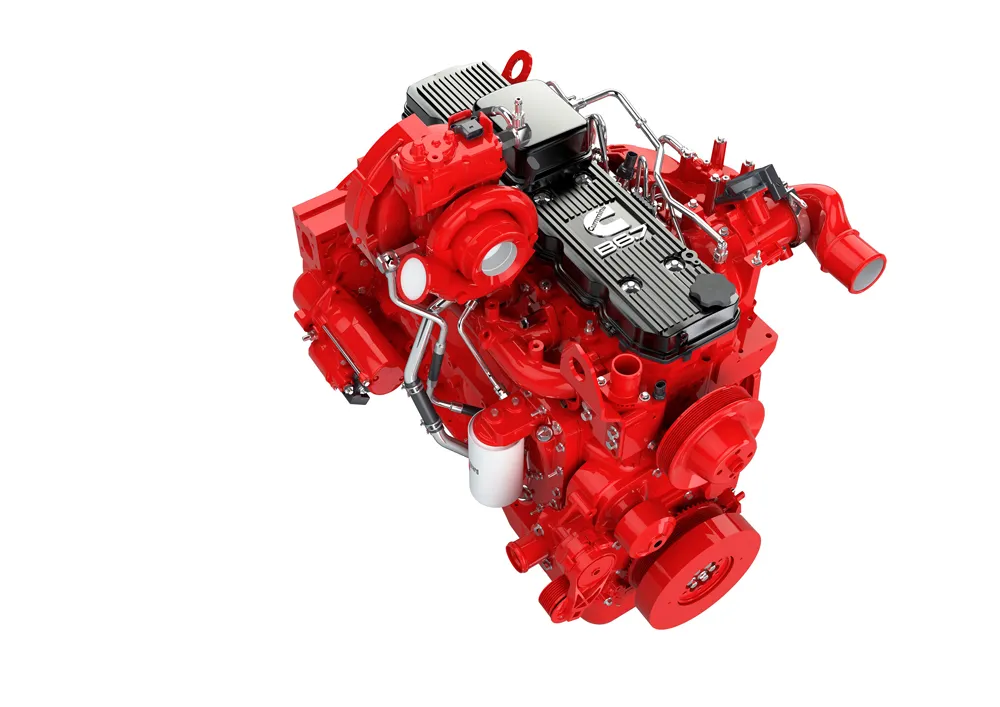

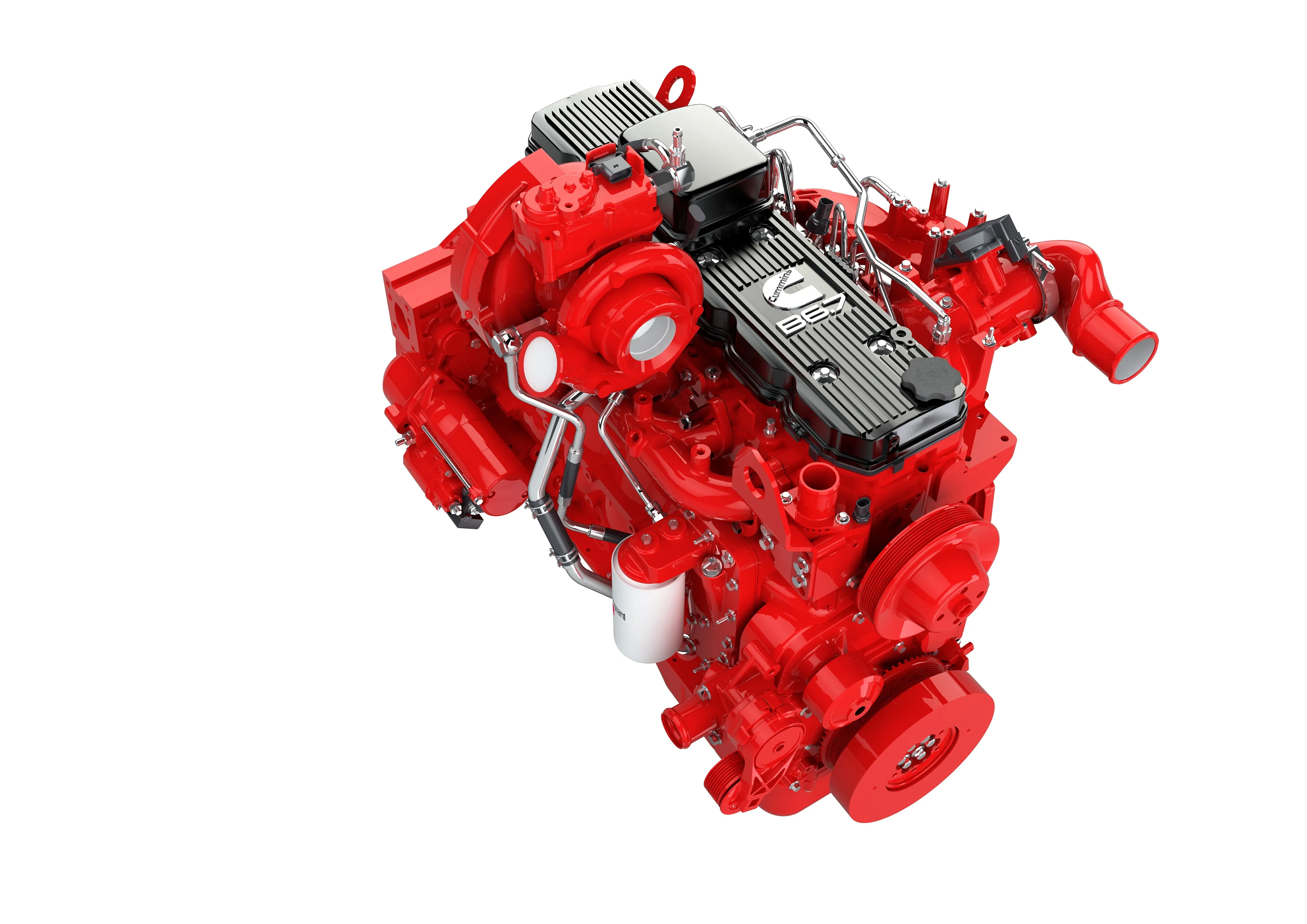

Sustainability measures in the construction process included the use of cleaner gas-to-liquid fuel for on-site machinery. GTL uses a refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel.

World Highways reported on the progress of construction in July last year.