A new automated levelling tool from MOBA is available that can help improve paving quality. The system is designed to deliver a smooth and even asphalt surface, by ensuring that the height and slope of the screed on the paver is accurately maintained. This is particularly important when the machine is moving in the vertical plane due to uneven ground or sub base conditions.

Achieving smoothness is important to the paving contractor. In many countries, highways authorities will pay more for smoother roads

October 9, 2015

Read time: 3 mins

A new automated levelling tool from MOBA is available that can help improve paving quality

The system is designed to deliver a smooth and even asphalt surface, by ensuring that the height and slope of the screed on the paver is accurately maintained. This is particularly important when the machine is moving in the vertical plane due to uneven ground or sub-base conditions.

Achieving smoothness is important to the paving contractor. In many countries, highways authorities will pay more for smoother roads and also penalise contractors that do not meet smoothness specifications.

Durability is a key factor in the need for smoother roads as these will last longer, improve fuel consumption (by 3-5%) and be quieter and safer to drive on. Levelling systems can help meet tight specifications and eliminate issues of poor smoothness in paved surfaces, improving efficiency for the contractor and quickly paying for the cost of the technology.

Levelling systems can be preset to pave a specific grade and slope and as the paver progresses the technology ensures the correct gradient is maintained, without any action from the operator. Levelling systems also remove the need for an operator to manually adjust the screed, providing significant savings in the cost of materials.

According to1228 MOBA, its technology can be fitted to any paver (as well as milling machines, compactors or graders). The technology has a number of key features and its grade control is crucial, managing the height of the paver against a reference level. The system can compensate for irregularities at the sub-base level as well as height movements of the paver during driving. Meanwhile effective slope control ensures that the transverse inclination of the paver is maintained on a defined level.

The real-time control loop continually measures and corrects the screed and the grade and slope controller uses sophisticated algorithms to maintain smoothness as well as the grade and cross slope. In use, the controllers continuously make small corrections to any transitions, while also maintaining elevation and cross slope set-points.

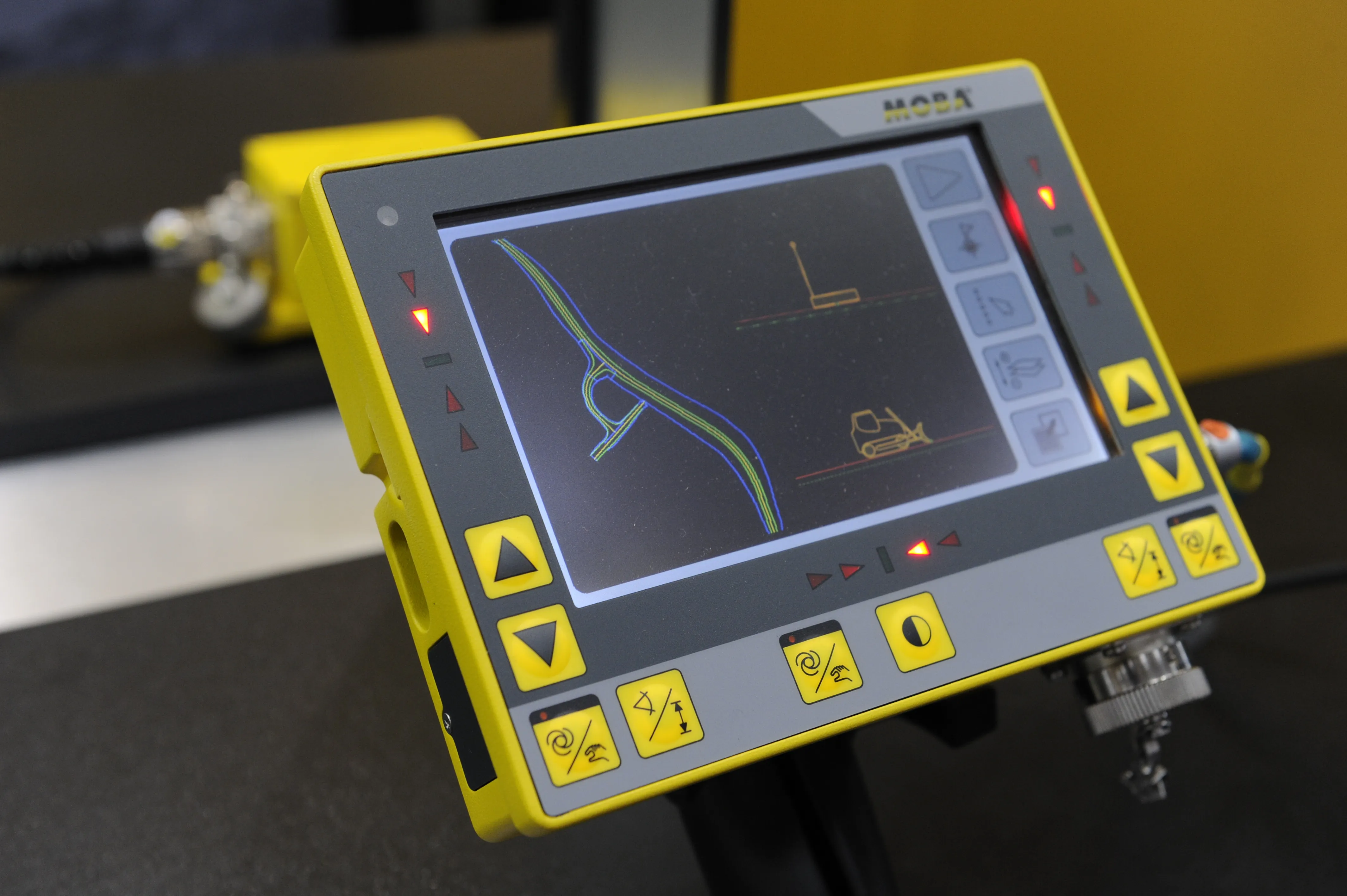

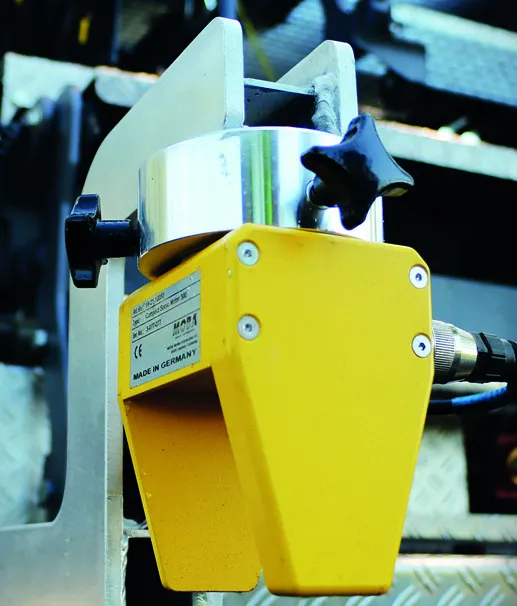

The improved MOBA-MATIC II levelling control system now has a larger screen and backlit keypad. And with a single control panel, both sides of the screed can now be controlled from one screen. Another major upgrade has been made to MOBA’s Sonic Ski sensor, which now has five sensors that more accurately determine the distance to the reference point.

The system is designed to deliver a smooth and even asphalt surface, by ensuring that the height and slope of the screed on the paver is accurately maintained. This is particularly important when the machine is moving in the vertical plane due to uneven ground or sub-base conditions.

Achieving smoothness is important to the paving contractor. In many countries, highways authorities will pay more for smoother roads and also penalise contractors that do not meet smoothness specifications.

Durability is a key factor in the need for smoother roads as these will last longer, improve fuel consumption (by 3-5%) and be quieter and safer to drive on. Levelling systems can help meet tight specifications and eliminate issues of poor smoothness in paved surfaces, improving efficiency for the contractor and quickly paying for the cost of the technology.

Levelling systems can be preset to pave a specific grade and slope and as the paver progresses the technology ensures the correct gradient is maintained, without any action from the operator. Levelling systems also remove the need for an operator to manually adjust the screed, providing significant savings in the cost of materials.

According to

The real-time control loop continually measures and corrects the screed and the grade and slope controller uses sophisticated algorithms to maintain smoothness as well as the grade and cross slope. In use, the controllers continuously make small corrections to any transitions, while also maintaining elevation and cross slope set-points.

The improved MOBA-MATIC II levelling control system now has a larger screen and backlit keypad. And with a single control panel, both sides of the screed can now be controlled from one screen. Another major upgrade has been made to MOBA’s Sonic Ski sensor, which now has five sensors that more accurately determine the distance to the reference point.