Contractor Tarmac helped provide a high quality surface for the UK’s famous Silverstone 1 race track, with the help of sophisticated technology from Topcon Positioning and Volz Consulting.

The Tarmac team laid the highly durable asphalt solution at the Northamptonshire track. The material was developed by the circuit design team, Dromo, in time for the event. The surface was designed to be resistant to the lateral loads and extremes of braking and cornering generated by racing cars and motorbikes.

An expert team led by Tarmac and Italian racetrack specialist Dromo, headed by Jarno Zafelli, took on complex resurfacing project. Tarmac’s road planing business, NRP, took the lead on the milling project, working with Topcon Positioning Group for its SmoothRide machine control technology to deliver a high surface quality. NRP employed 3D GPS guided planing during the removal of the previous track surface. The team needed to alter the entire camber of the 5.5km circuit to optimise water run-off and adjust gradients.

It was to be the first use of the technology in the UK. Sjoerd Stoové, 3D paving specialist at Topcon Positioning Group, said: “Racetracks are completely different from other roads – it’s very specialist work. This is mainly because on a normal road there are separate lanes, but on a racetrack the ideal racking line changes constantly from left to right. With Silverstone, there also needed to be two ‘crowns’ in the road, which were not always in the same spot, and there were very tight corners requiring quick camber changes over short distances.”

Rather than replacing the top layer, the track required a complete redesign. Sjoerd explained: “If you only take off the top layer and replace it, you are essentially just replicating the existing situation. We needed to create a new surface to eradicate any risk of bumps, and also so we could shape a new camber that would make sure all water runs off to avoid aquaplaning.”

The project team first carried out a scan of the existing surface to identify bumps. This scan data was then converted into a 3D digital terrain model (DTM) using Topcon’s Magnet Collage software, with the model being used to inform the new design.

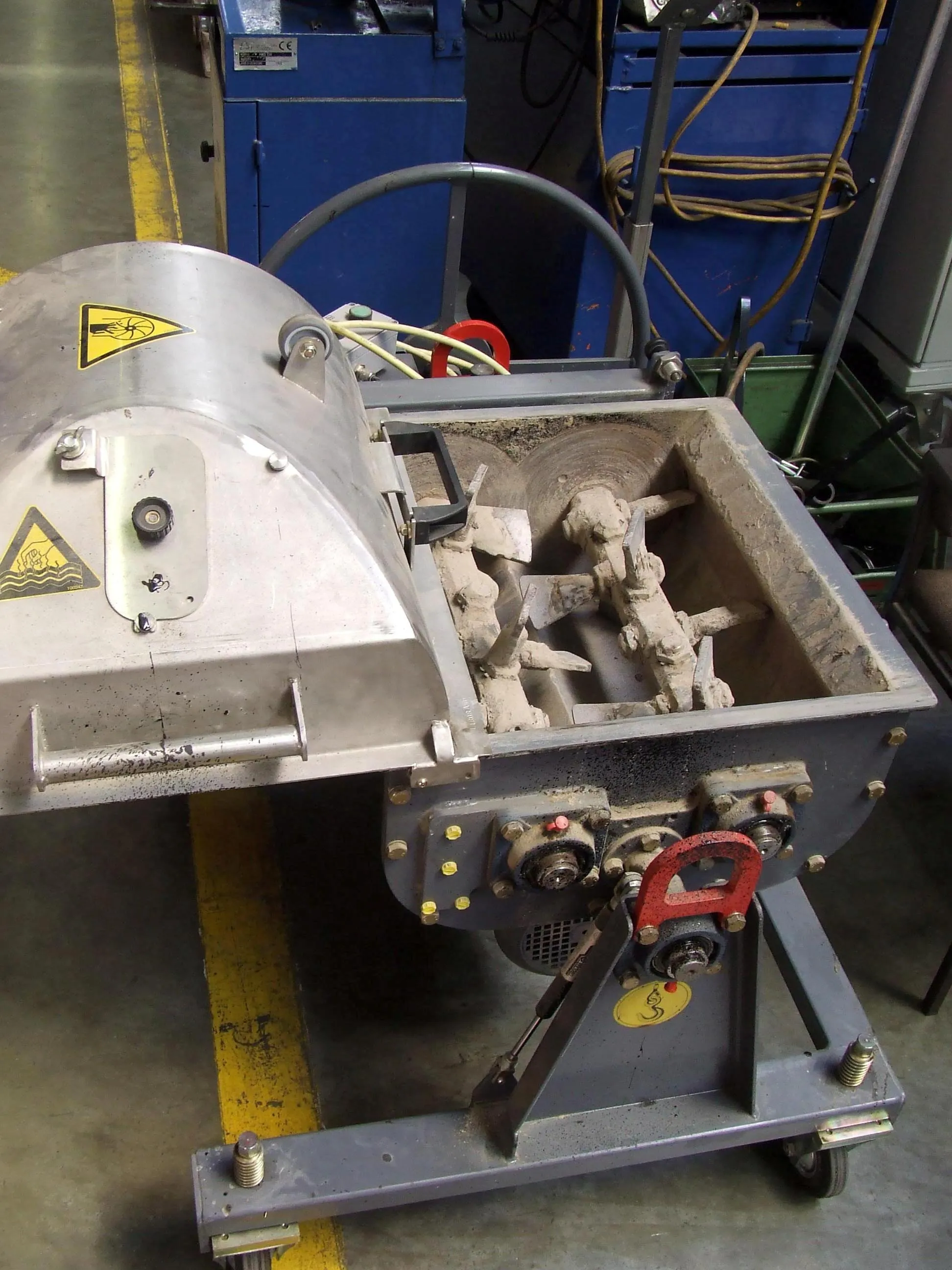

It was decided that milling machines would be used to shape the new track as they can make the surface extremely level, meaning the subsequent paving can be done in a constant layer thickness. Sjoerd Stoové added: “The difference between the existing surface and the new design resulted in an average milling depth of 70mm over the whole racetrack. However, the problem with averages is that in some places you need to mill more, where in others you need to mill far less, or even not at all.”

Sensors on the two Wirtgen W210Fi machines were used to pinpoint the depth of the milling drum on both sides then, based on the desired depth and the actual depth, the machines were told to move the drum up or down. Sjoerd said: “This way, the new design is executed to millimetre accuracy.”

Milling of the 87,000m2 track took just three days and two nights. There was also no need for surveyors to paint depth numbers on the asphalt or create stringlines, saving days of survey work. And, because the milled surface was accurate, Tarmac was able to precisely calculate the amount of material required when it came to paving using its state-of-the-art BPO ASPHALT management system

Three paving machines ran in echelon during installation to eliminate joints across the width of the track, while digital paving technology was used to guarantee quality during the laying and compaction of the asphalt. Tarmac was able to address the logistical challenges of delivering material from multiple sites with the advanced BPO ASPHALT management system.

The software calculates the most efficient way of completing a scheme by working out how many delivery trucks are required, precise timings for their arrival and departure, as well as the total tonnages achievable. It also provides site supervisors with live updates throughout each shift, supporting real-time decision-making through a comprehensive supply of data.