In the US, 23 states have written intelligent compaction (IC) specifications for asphalt paving jobs and more states are expected to follow. Among those states with IC specs is California.

However, like many other states with IC specs in place, California has yet to require their adoption for most highway paving jobs. Many believe that

It’s only a matter of time; contractors with proven experience with IC systems will be most competitive when more jobs require the use.

Granite Construction, a 100-year-old civils contractor is one such company using IC specifications right now. The company’s contract for the Sacramento International Airport is gaining Granite valuable experience of IC specifications, knowledge it can use on projects in within the 50 states in which it does work. The company is relying on Volvo Compact Assist to see passes, temperature and real-time density calculations on the project.

Sacramento has more than 110,000 aircraft operations a year. Along with partner general engineering contractor DeSilva Gates, Granite Construction began work on a taxiway reconstruction in August 2016. While Granite had not yet been faced with bidding on a Caltrans IC project that required density or stiffness measurements, they expect that it’s coming. Granite Construction saw the 35,000ton taxiway job as the perfect opportunity to gain experience with the technology.

X-Head: Stakes are high

If the company could successfully pull off the FAA-specified 96.3% density for this project using IC for the first time, then the bonus would pay out at 6% of the US$2.5 million paving budget. Standing in the way were challenging weather conditions, a tight timeline and strict Federal Aviation Authority requirements, not to mention getting to grips with a new technology.

The job consisted of four phases to replace all the outdated eastern taxiways which did not meet modern lighting, width and shoulder requirements. “This kind of job is our bread and butter, from demolition and earthwork to paving with our own asphalt mix from our local plant in Sacramento,” said Kelly Curtis, project manager at Granite Construction.

Phase one included removing the taxiways. The old pavement was a 10-inch (254mm) asphalt section over multiple base courses—a typical taxiway section.

Earthwork was phase two of the project and lasted until October 2016. It included building shoulders and widening a short section of the taxiway. All asphalt grindings from the old taxiways were recycled and incorporated into the base courses for the new shoulders. Granite then re-graded the old taxiway base courses to the new alignment.

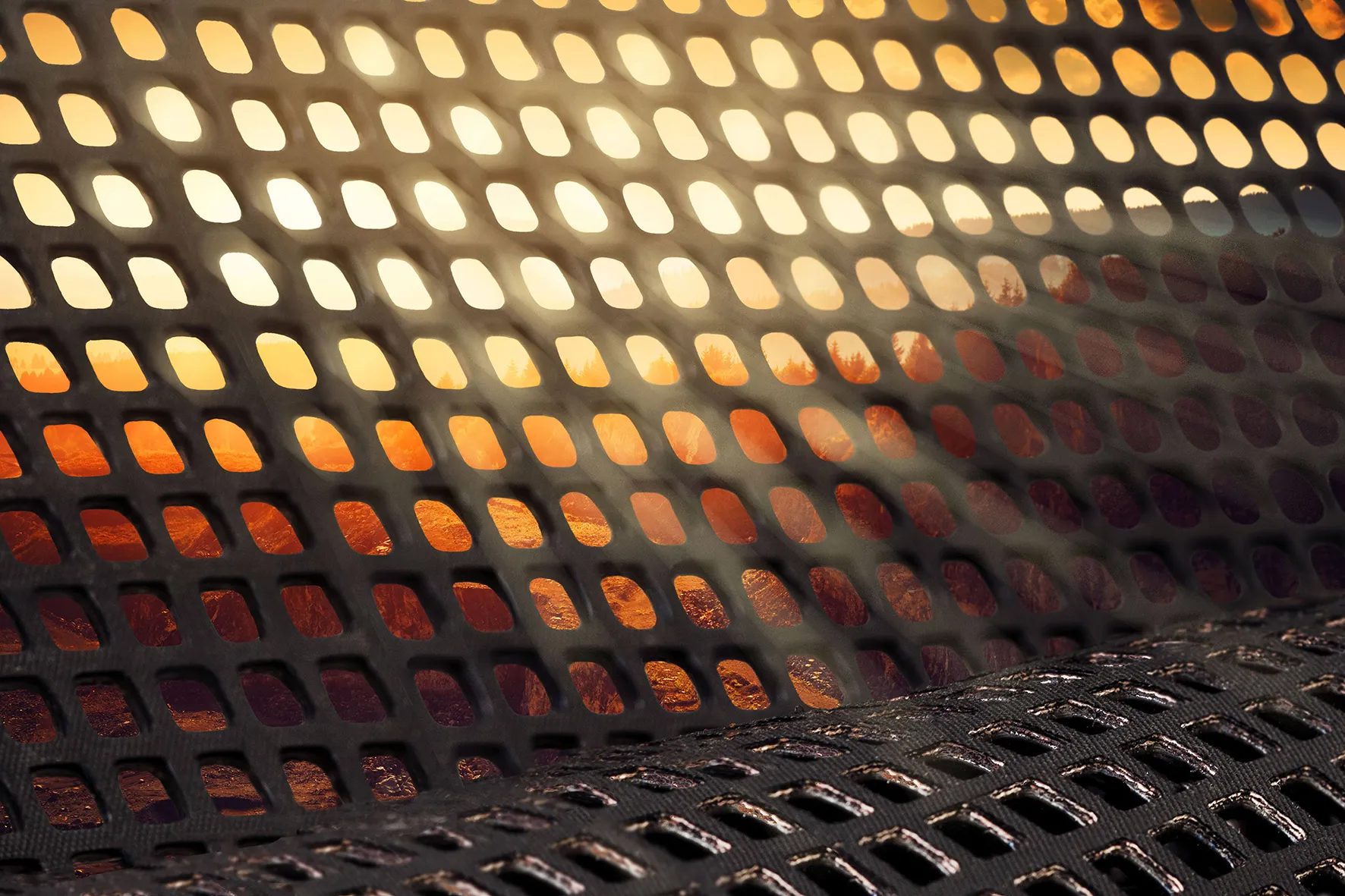

Volvo Compact Assist with Density Direct provides pass mapping, temperature mapping and density calculations to the operator in real time.

With the entire eastern taxiway closed, time was of the essence, meaning Granite Construction had to work through much of the winter season. A Sacramento winter is wet with near-freezing temperatures. Reopening the taxiway on time, while adhering to the stringent specifications with minimal rework, took a well-coordinated effort.

Asphalt mix for the project was required to meet the FAA P-401 standard at three-quarters of an inch (19mm). Target density for the project was 96.3% and had a percent within limits (PWL) specification of 90%. The PWL looks at not only the average but the standard deviation. Granite Construction had a goal to get the bonus 100% of the time by hitting a PWL of at least 96%, which is 6% above the PWL specification set for the project.

Meeting these specifications and staying on schedule was a tall order, but one that would pay off.

X-Head: Compact Assist

Granite Construction has had a well-established quality control (QC) process for years. For the Sacramento job, that meant three QC workers on site and periodic core density and nuclear gauge testing. Granite also wanted to slowly cycle in an IC system to compare what they were seeing with their existing QC processes.

The company took advice from their equipment dealer, Volvo Construction Equipment and Services of California. “They felt like if they waited until there was a job with an IC requirement and stubbed their toe, it would be costly. So, they were going to treat this project like it was an IC-spec job,” says Jake Zayas, VCES branch manager.

Granite eventually rented two compactors—a DD110B and DD120B. Both are equipped with Compact Assist, the Volvo Intelligent Compaction system with Density Direct. Compact Assist has pass mapping and temperature mapping functionality, as most IC systems do. However, unlike other programs, it also provides density estimates in real time rather than intelligent compaction measurement values (ICMV), which are essentially a measurement of stiffness.

ICMV has been a source of confusion for many of his paving customers. “With ICMV, you’re seeing a value that doesn’t represent something in the job’s specifications,” explains Zayas.

“You might see a value of 40 on the screen and then your operator has to figure out how that correlates to density. It’s much less complex to see an actual density calculation on screen. In real time you can see, for instance, 95% relative density displayed on the screen, and know exactly what that means, because it’s tied to your job specification. That’s a big part of why Granite came to us for this project.”

X-Head: Confidence increases

Granite Construction equipped both the breakdown roller and the finish roller with Volvo Compact Assist, allowing them to scale back on other QC efforts.

To help Granite Construction get started, VCES provided training on the system and assistance with calibration at the beginning of the paving phase of the project. Calibration allows the system to become familiar with the asphalt mix used for the job for accuracy when calculating density values.

The calibration process requires that the operator make several vibratory passes while the system collects data or trains itself for that specific material. Once calibrated, the system can save up to six unique lifts of asphalt per job, allowing the operator to select differing lifts during the daily work cycle.

“I would say the calibration process typically takes about three minutes, assuming you have no hiccups,” Zayas says. “But if you do have a hiccup, it can actually be a good thing. For instance, if it’s not calibrating, it probably means you’re running at the wrong amplitude for the asphalt mix, so it’s an added layer of quality assurance.”

Granite Construction found that after using Compact Assist alongside current QC/QA practices the density provided by Compact Assist with Density Direct was consistent with core density and nuclear gauge testing. This allowed the team on the job site to see the pass map and make corrections as needed. They used the first half of the project to gain confidence in their overall approach. For the second half, their intention was to rely more heavily on Compact Assist.

With the initial training and calibration complete and some work with the system under their belts, operators’ trust in the system built up. Halfway through the project, they saw an opportunity to reduce QC costs by removing one dedicated QC team member from the project. In fact, this was an opportunity to train a new QC team member, while remaining confident the project was on track.

“Part of what a QC is doing is watching your rolling patterns,” says project manager Curtis. “Now here’s a tool that tells you how many passes you’ve made over every section of the pavement, so you don’t need that guy to be as attentive. It was definitely an added layer of comfort.”

With their confidence level heightened, Granite rounded out the second half of the project with increased reliance on Compact Assist, to great effect. “We actually hit the bonus on 100% of the paving,” says Curtis. “Most of the time we were able to hit 100% PWL because we were getting compaction in the 98-99% range, which puts us so high above the job specification that, as far as that PWL is concerned, we’ve got a 100% score, essentially.”

Moving Forward with Technology

Granite has gained valuable experience at a time when job specifications will increasingly require include IC. “I think in the next 5-10 years, there’s won’t be a roller that doesn’t have some form of IC on it,” Zayas said. “It’s not just about meeting some requirement written into the job specs. There’s added value to the system. Even paving someone’s driveway, you have data to back up that you met compaction needs. It’s kind of like an insurance policy.”

*Granite Construction, based in Watsonville, California, recently won a $23 million runway rehabilitation contract at San Diego International Airport. The deal includes milling and replacing around 230,000m² of asphalt concrete pavement, reconstruction of a taxiway, upgrading of lighting and signage and new striping and marking. The award comes just after another runway win, a $41 million reconstruction contract at Los Angeles International Airport.

VolvoCE

Granite Construction