This month we look at how pavement testing technology is responding to extremes of temperature, showcase concrete testing in Doha and look at how water drops could help identify delaminated bridge decks - Kristina Smith reports

One of the biggest challenges that pavement engineers face is how to design for extremes of temperature. Designing for cold weather can result in problems at higher temperatures – and vice versa.In Scandinavia, generally a cold climate, they are facing this problem. In the summer, temperatures in the pavement can reach 50°C when the sun shines for more than 20 hours. This means that rutting is one of the most frequent problems on roads carrying heavy traffic.

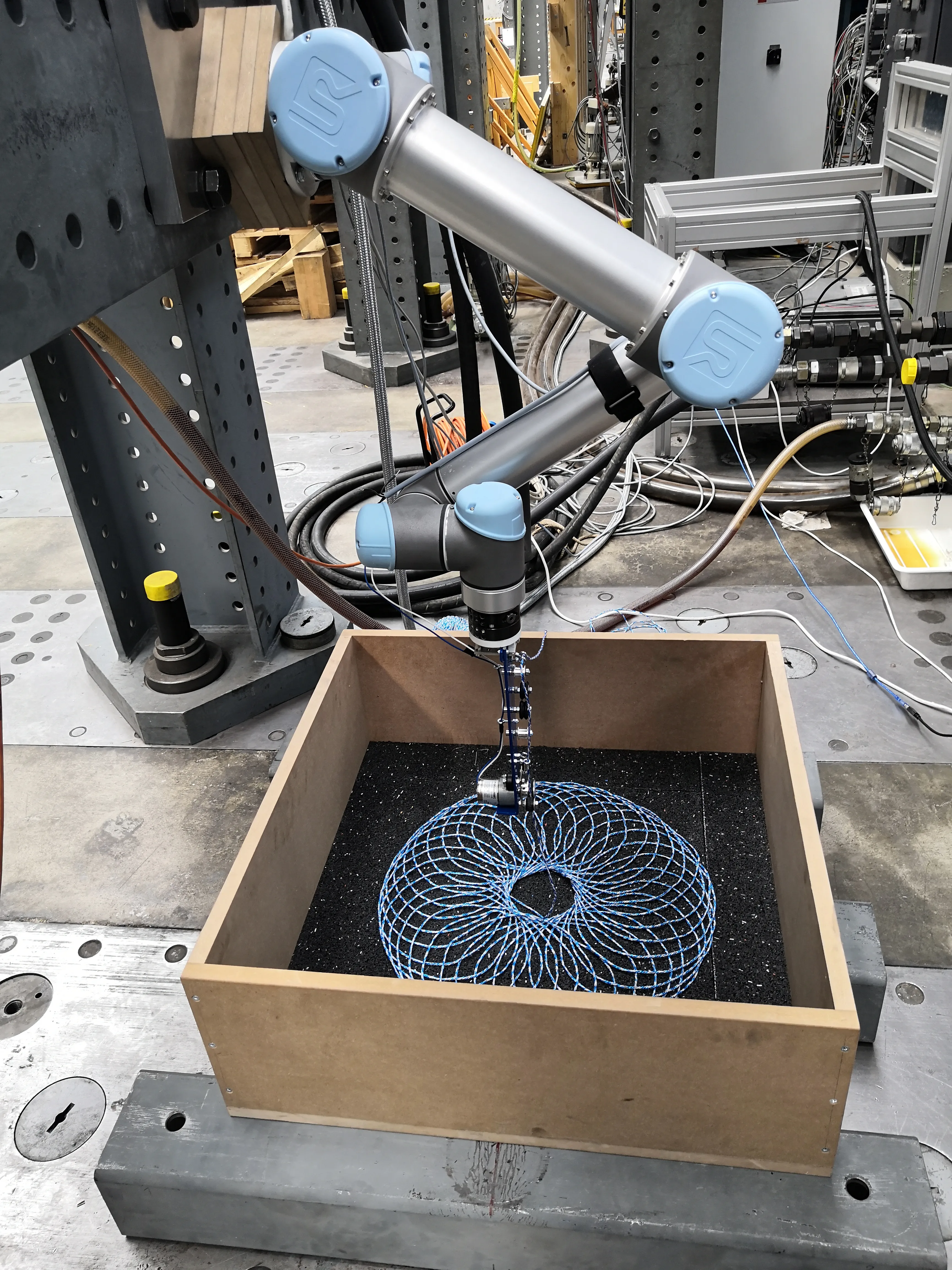

Researchers at the Swedish Road and Transport Research Institute,

“This method will help us get the optimum solution for a pavement design,” said Hassan Hakim, who with CTI colleague Safwat Said has carried out the research. “We can use a modified bitumen and understand how the asphalt changes due to the temperature. That way we can find something that is more resistant in the hot weather but still soft in the cold weather.”

The shear test involved gluing a cylindrical specimen to two plates. One plate exerts a sinusoidal force, mimicking acceleration or braking force while the other applies a constant compressive force equivalent to the weight of the vehicle. The frequency of the sinusoidal load and the temperatures are varied.

VTI has also gone on to create a model which can estimate the rutting development in the pavement. Hakim said that VTI has compared the model’s predictions against the actual rutting on a road which has been in use for 10 years with “good results.”

VTI also offers a Prall tester, which was launched in early 2012, required for climates such as Scandinavia where studded tyres are used in winter weather. The VTI Prall is designed to meet the requirements for method A in the European standard EN 12697-16:2004 “Bituminous mixtures- Test methods for hot mix asphalt- Part 16: Abrasion by studded tyres.”

VTI would like to make it clear that it was not involved with the development of the Cooper Prall tester, as stated in the May 2012 issue of World Highways and that its Prall tester is commercially available.

Water droplets could help detect bridge damage

Researchers at Brigham Young University in the US have discovered a potential new means of testing the integrity of bridges: dropping water onto the deck and recording the sound.

Brian Mazzeo and W Spencer Guthrie reported the results of their study ‘Acoustic impact-echo investigation of concrete delaminations using liquid droplet excitation’ in the journal Non-Destructive Testing and Evaluation International.

Impact-echo testing is often used on bridges and other structures. Engineers drag heavy chains over the bridge deck and listen to the sound it makes. Where a concrete structure has delaminated, often due to rusting reinforcement, a different sound is heard.

This method can be costly and disruptive, however, as it often requires lane closures. If the sound of water droplets, sprayed over the deck from a moving vehicle could be used, it would vastly speed up the process.

It is early days for this new method of testing. More research will be required before these findings can be developed into a useable solution.