These machines suit a range of compaction applications and tend to be shorter than comparable articulated machines, with tighter turning circles. This suits the machines to urban applications where space is at a premium while also being easier to transport.

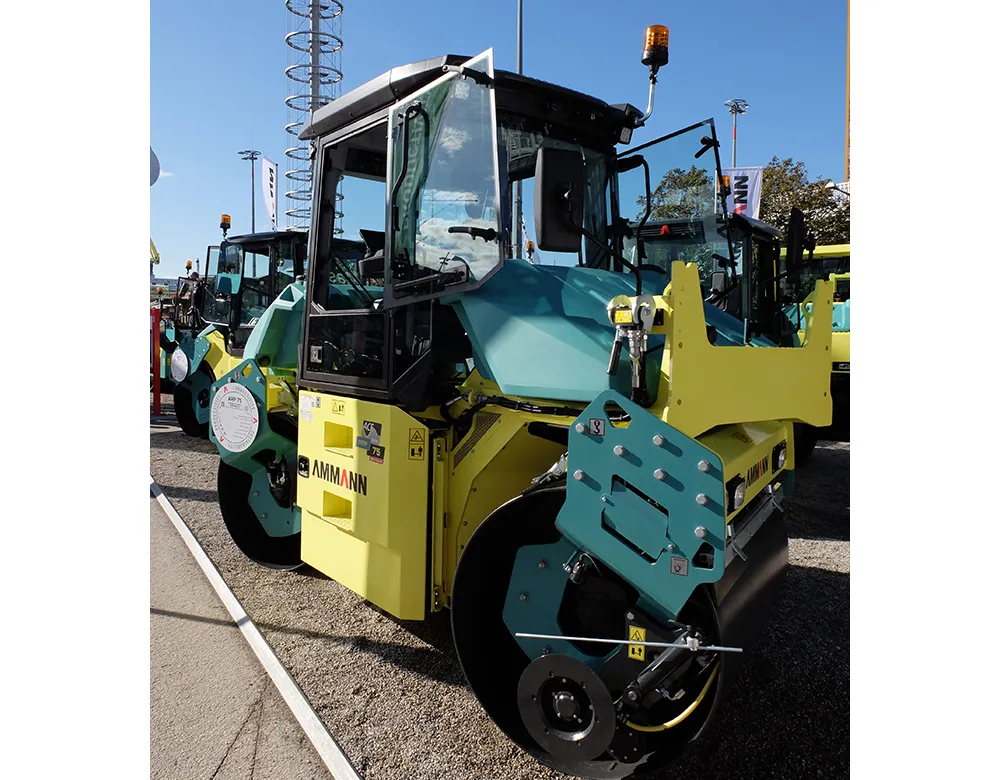

The latest drum steer model from Ammann is a 7.5tonne class machine, the ARP75. This model is powered by a 55.4kW Kubota diesel that meets the Tier 4 Final/Stage V emissions requirements and is said to offer low noise and smoke emissions as well as high productivity and fuel efficiency.

The firm says that the machine delivers a combination of productivity and ease of servicing, with low running costs. Meanwhile, a new cab is said to offer high all-round visibility as well as operator comfort and ergonomic controls. Touchscreen controls allow the operator to set key working parameters, while there are also controls on the joystick and a number of switches. The control layout has been optimised to make the machine simpler to operate.

The compactor is equipped with dual amplitudes and multiple frequencies as standard. This allows the operator to set the working parameters to suit duties on a range of surfaces. The precise controls ensure that the machine can be used to compact thin layer wearing courses without risk of crushing aggregates.

The machine is equipped with 1.5m-wide split drums and offers a wide offset that allows for a maximum compaction width of 2.72m. The compactor is also equipped with Ammann’s proven ACE force compaction control system, which helps to optimise working and can record key job data. In addition, the ACE force system stores data on location, so that it is possible to analyse what compaction work has been carried out where on a jobsite. The machine also has the Servicelink package that helps with predictive maintenance and ensures maximum uptime.

A key feature is the 900litre water tank, said to be the biggest in its class although the machine is compact in size given its performance. A range of options are offered for the machine and these include an edge cutter, chippings spreader and a combi version with tyres instead of a front drum.

From BOMAG meanwhile come the new BW 154 and BW 174 pivot-steered tandem rollers. According to BOMAG, ease of control is a key feature of the machines, which are both fitted with the latest myCockpit system. This novel control system offers a choice of three operating concepts. Operators have a choice of touchscreen, rotary pushbutton switch or classic joystick controls. The touchscreen allows full control over functions and meets the need for digitalisation, though the rollers can also be operated using the rotary pushbutton on the control lever.

The operator can configure default settings and operate and control the functions using the touchscreen. In addition, it is possible for different operators to set their own individual user profiles or switch to default settings. Another feature is a preset operating profile aimed at use by the truck driver when loading the machine for transport.

The BW 154 and BW 174 tandem rollers are available in several variants and with a wide range of equipment. They offer working widths of 1.5m or 1.68m and operating weights of 7.1tonnes and 9.8tonnes. Three compaction systems are offered: Asphalt Manager 2, vibration or the split drum oscillation TanGO4. The Asphalt Manager system has been simplified and regulates amplitude as well as compaction direction. This allows it to achieve optimum compaction quality with minimal passes.

The Asphalt Manager system allows the operator to concentrate on the rolling pattern and other machines working alongside, as well as being suited to compacting low-temperature asphalt.

BOMAG offers optional extras including a second monitor at the rear of the cab for reversing, four additional mirrors on the cabin and rear frame, up to 16 LED lights, a chip spreader and a measuring technology interface for data transmission to the BOMAP app.

Dynapac’s model for the drum steer sector is the CG2300, which is said to feature a high comfort cab and good drum edge visibility due to the extended sideways sliding seat and steering assembly. Good ergonomics as well as smooth and precise steering are offered by the electronic mini steering wheel and four-piston steering system.

The clear control panel gives operators the information they need. Further information can be provided through the optional Dyn@Lyzer software, which gives the full documentation of temperature, compaction Evib value and number of passes on each section of the asphalt.

The Dynapac CG2300 is 3.99m long x 2.99m high, has an inner turning radius of only 2.65m and an offset of 1.2m, making it easy to transport and manoeuvre in confined spaces.

The Dynapac CG2300 is equipped with EcoMode as standard, which reduces fuel consumption by more than 15%. In addition, noise is also lowered through the use of a hydraulically-driven temperature-guided cooling fan, which only operates when necessary.

Use of a double pump vibration system eliminates the need for a vibration valve, making the system more efficient, aiding servicing and reducing fuel consumption. Both pumps, one for the front drum and one for the rear, can simply be shut off if required.

The efficient eccentric weights and the serial start-up of vibration makes the system even more efficient, keeping fuel consumption and CO2 emissions as low as possible.

Advanced options are also available, such as an edge presser/cutter (left and right) and a chip spreader. A sprinkler system with double sprinkler bars and pumps, and a capacity of more than 700litres of water, ensures uninterrupted operation.

The new HX series tandem rollers from Hamm feature pivot steer configuration, replacing the earlier DV+ variants. Improved performance is claimed with advantages such as intuitive operation with Easy Drive, high performance data, high comfort and the Smart Compact digital compaction assistant.

Designed for asphalt compaction, the 7tonne class HX 70i model features a 55.4kW diesel while the 9tonne class HX 90i is powered by a 74.4kW diesel. Both engines meet Tier 4 Final Stage V emissions requirements and the machines are said to achieve high surface outputs on large construction sites.

The company claims that the machines deliver high-quality compaction and is offering an array of variants to suit different customer requirements. Models are offered with split and non-split drums, as well as oscillation and combination variants.

An integrated automatic reversing system is fitted that brakes and then accelerates the rollers quickly and smoothly. The electrically-adjustable seat also turns to face the direction of travel automatically. New LED turn indicators are fitted and the fully glazed panoramic cab offers an improved field of vision with an excellent view of the drum edges. The Easy Drive operating system combines an ergonomic operator platform with sophisticated operating structure. Despite the extensive machine functions, operation is said to be intuitive and very quickly learned. Steering is performed with the steering wheel; all other important functions are operated via a joystick and the multifunction armrest.

The Smart Compact compaction assistant is available and decides compaction automatically and individually for each drum. This selects whether to compact with vibration and big or small amplitude, with oscillation, or statically. The driver then enters whether a base, binder or asphalt surface course is to be compacted. The assistant even evaluates data about the condition of the asphalt, optionally incorporating local weather data from an integrated weather station.

Hamm also offers the option of integrating systems for avoiding collisions with a PDS (proximity detection system) interface. In addition, the telematic system JDLink is on-board in all models, which can be used to call up elements such as performance data for rollers, fill levels, error messages, operating hours or service intervals.

The HX series rollers are offered in 7tonne and 9tonne variants and are available in nine versions including models with two vibrating roller drums, an oscillation and an vibrating roller drum as well as combination rollers.