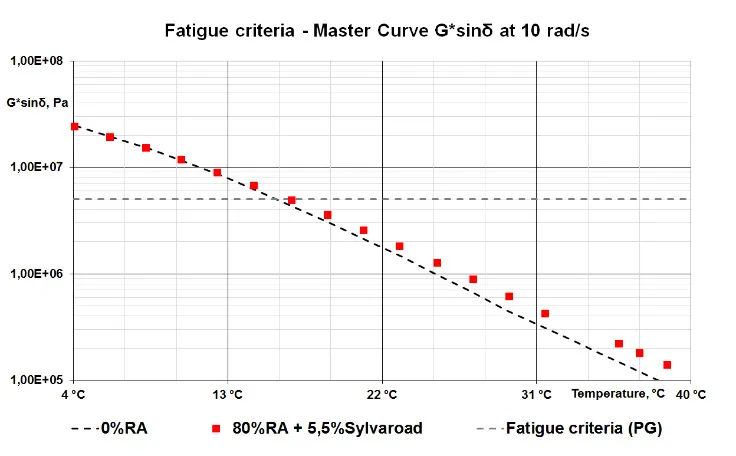

The cold climate found in regions such as Canada and the northern regions of the US and Europe poses a particular challenge to engineering a long-lasting, high-quality pavement. Pavements constructed with asphalt in those regions are affected by the asphalt binder’s sensitivity to temperature. Choosing a binder wisely is imperative for getting the best value for money when constructing a highway.

If the climate it is too warm, the binder becomes soft, which may lead to rutting. If it is too cold, the binder can become too brittle, which causes cracking. It’s important to assess the ability of available materials to withstand these temperature extremes and then optimise the binder and mix appropriately.

On pavements in cold climates, Transtec focuses on binder selection, especially the low-temperature properties of the binder. High-quality crude oil is often the key to improved low-temperature properties. Binders can be further modified with polymers to ensure even higher performance.

Aggregates used in the asphalt mixture can also be engineered to resist rutting and cracking. This begins with assessing the source quarry or pit, crushing methods used and the final size and shape of aggregate particles.

Design-build and public-private partnership - P3 - projects commonly specify rigorous pavement performance requirements, including cracking, rutting and ride quality. To meet these requirements when constructing pavements in cold climates, Transtec recommends designing and constructing to a higher standard than the minimums usually specified. It is often better to construct pavement smoother than typically done for other projects in the area for the pavement to remain smooth during its life. To achieve this, construction methods that improve smoothness must be implemented.

Engineering a smoother pavement improves its long-term performance. The time it will take to reach the pavement’s performance limit is extended, which means there will be fewer interventions or overlays, reducing the impact to the public traveling on the road. Fewer interventions also decreases the pavement’s life cycle cost, which saves taxpayer money.

Because it is inherently difficult to build large-scale projects under stringent performance requirements in cold climates, it is essential to choose a pavement analyst partner, such as Transtec, with expertise in this particular type of project. The analyst should provide independent evaluation and guidance for the developers to ensure a quality, long-lasting pavement.

Transtec Group delivered an expert review and life-cycle recommendations for the Southwest Calgary Ring Road public-private-partnership project in the city of Calgary. The project will, when finished, be a circle around the city. The Southwest section of the project, which broke ground in the summer of 2016, is one of the last segments to be finished and is expected to be open in 2021.

Transtec worked with Mountain View Partners which includes

The firm’s cold climate experience extends to a major project in the Canadian city of Winnipeg – sometimes referred by locals as Winterpeg. January temperatures can average around −16°C, occasionally dropping below −40°C. Air temperature drops below −30°C average around 13 days a year. Transtec delivered a plan for pavement design and life-cycle advisement for the P3 project Southwest Transitway project with the Plenary Group.