From FAE come highly versatile machines in the shape of the RCU55 and RCU75 remote control carriers. Developed initially for land clearance, these can be used for a wide array of tasks, including operation in hazardous areas. Where ground conditions may be too hazardous for personnel, the RCU55 and RCU75 are heavy-duty, remote control units that can handle many of FAE’s specialist attachments such as planers and cutters. The heavy weight means that they retain good stability, even in hard cutting or planing duties.

Meanwhile, the firm’s latest EX unit is designed for use on excavators in the 8-14tonne class and weighs 700kg, without including the attachment plate. This unit can cut a slot 460mm wide to a depth of 140mm.

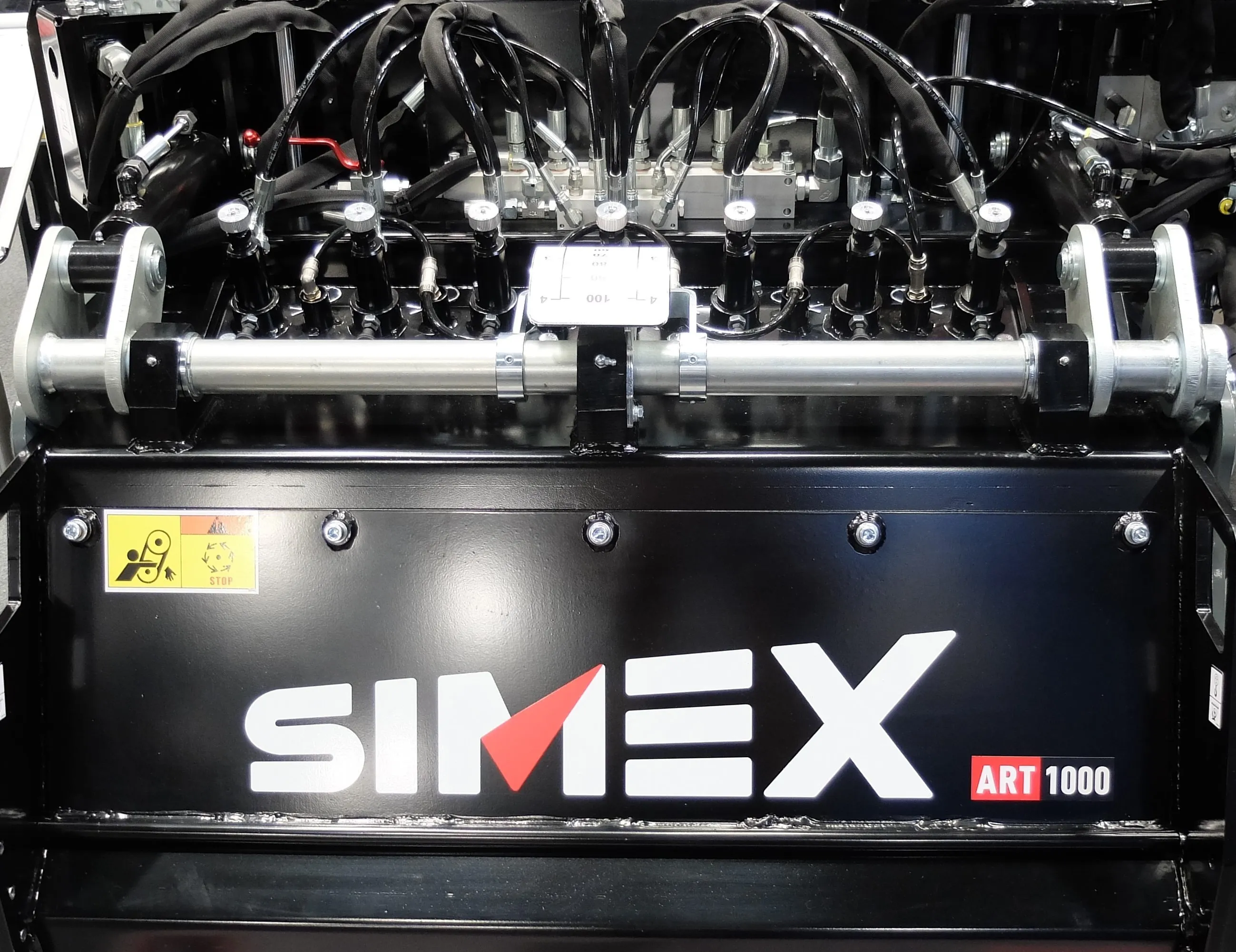

The new ART1000 unit from Simex offers fast and effective road repairs. The unit is suited to use on urban roads and offers a cost-effective solution for repairs and maintenance works. This sophisticated unit is designed for use on a high performance skid steer loader with high flow hydraulics but is more sophisticated than a basic milling unit.

Alessandro Ferrin from the firm commented, “It’s the most advanced attachment we have and we spent five or six years developing it. This is not a common milling attachment.”

He said that the unit offers users the option of cold-in-place recycling allowing speedy, low cost road repairs. Additional training is required for users of the machine operator to ensure that repair works are carried out properly. Apart from the skid steer carrying the attachment, the only other piece of equipment required onsite is a small twin drum compactor.

The milling drum at the front of the unit breaks out the old surface, with a second revolving cutter then reducing the material to the 0-15mm size. Ferrin said, “’Everything is controlled by the system that maintains a constant percentage of additive. The unit can be used for repairing local roads quickly and as almost all of the material is from the surface, with only a small percentage of additives, it reduces repair costs.

Repairs can also be carried out repeatedly on the same stretch of road. The machine has a working width of 1m and can cut to a maximum depth of 100mm, although Ferrin said that in use, 30-70mm is more typical. Ferrin added that the firm will broaden the range with smaller and larger versions, although customers may have to wait two years for them to be available.