Congestion is a major problem in certain areas of US state Florida. A large number of commuters and tourists means that central Florida’s Interstate 4 (I-4) highway suffers particularly from congestion. Its proximity to Disneyland means that the traffic often comes to a complete standstill.

A 2012 report from the Texas Transportation Institute ranked Orlando 13th in the US for traffic congestion, with more than 1.5 million daily trips on I-4. The report estimates that each frustrated commuter wastes about 45 hours/year sitting in traffic.

With Central Florida attracting 59 million visitors/year, it is clear that I-4 is in need of a major update. But an analysis showed that the project would take 27 years to complete with Florida Department of Transportation (FDOT) funding alone.

As a result, a novel PPP arrangement is being used that will allow the project to be completed in less than seven years.

This allows the FDOT to share financial risk with a team of private companies, which finance a portion of the project.

Three major infrastructure firms,

Close to 2,000 workers will be involved during the project. The difficult terrain means that the plans involve the construction of no less than 140 bridges. There are 13 bridges being widened, while more than 74 are being replaced and a further and 53 new bridges are being built along the 34km route of the highway.

Project innovations include the use of recycled materials, such as existing concrete and limestone. The work also includes the use of carefully designed landscapes, lighting and bridges, to optimise the aesthetics.

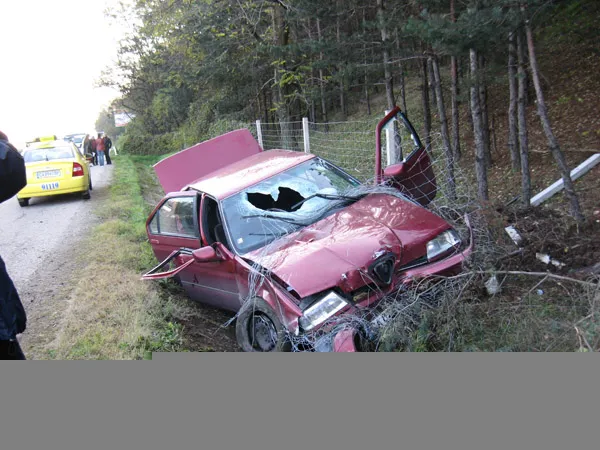

Because the project is being carried out in the urban environment as well as alongside live traffic in some areas, safety is a key issue and the project team has placed this as a priority for the site personnel.

SGL’s safety policies include granting every person on site the authority to stop work if he or she notices a potential safety problem. This encourages each member of the project team to look out for everyone else.

Much of the equipment being used for the work has been supplied by

The Volvo machines are being used for clearing and site preparation, pipe-laying and bridge demolition, using Volvo HB450 Plus and HB2400 Plus hammers.

The Volvo ECR305C is a short tailswing crawler excavator and its use is especially important on the I-4 project because much of the work is being carried out close to local homes and businesses, and many roads will be open to traffic during construction.

The project spans territory rich in waterways, fish, wildlife and sensitive environments. SGL says it is proactive in protecting natural resources, controlling spills and erosion at job sites. More than 93,000 native plants, trees, and shrubs will be planted in concert with native grasses to create a signature corridor in the region. SGL has also established a waste reduction goal to reuse and recycle 98% of all construction and demolition waste generated by the project.

To maximise site safety, operator training has also been placed as a priority. When SGL bought its Volvo CE excavators, the manufacturer also supplied a training simulator. As part of its hiring policy, SGL has been ensuring that all excavator operators brought in for the job have sessions on the simulator, to assess their abilities.

The simulator is also being used to help train up excavator operators, due to insufficient numbers of skilled and experienced personnel to work on this massive project.