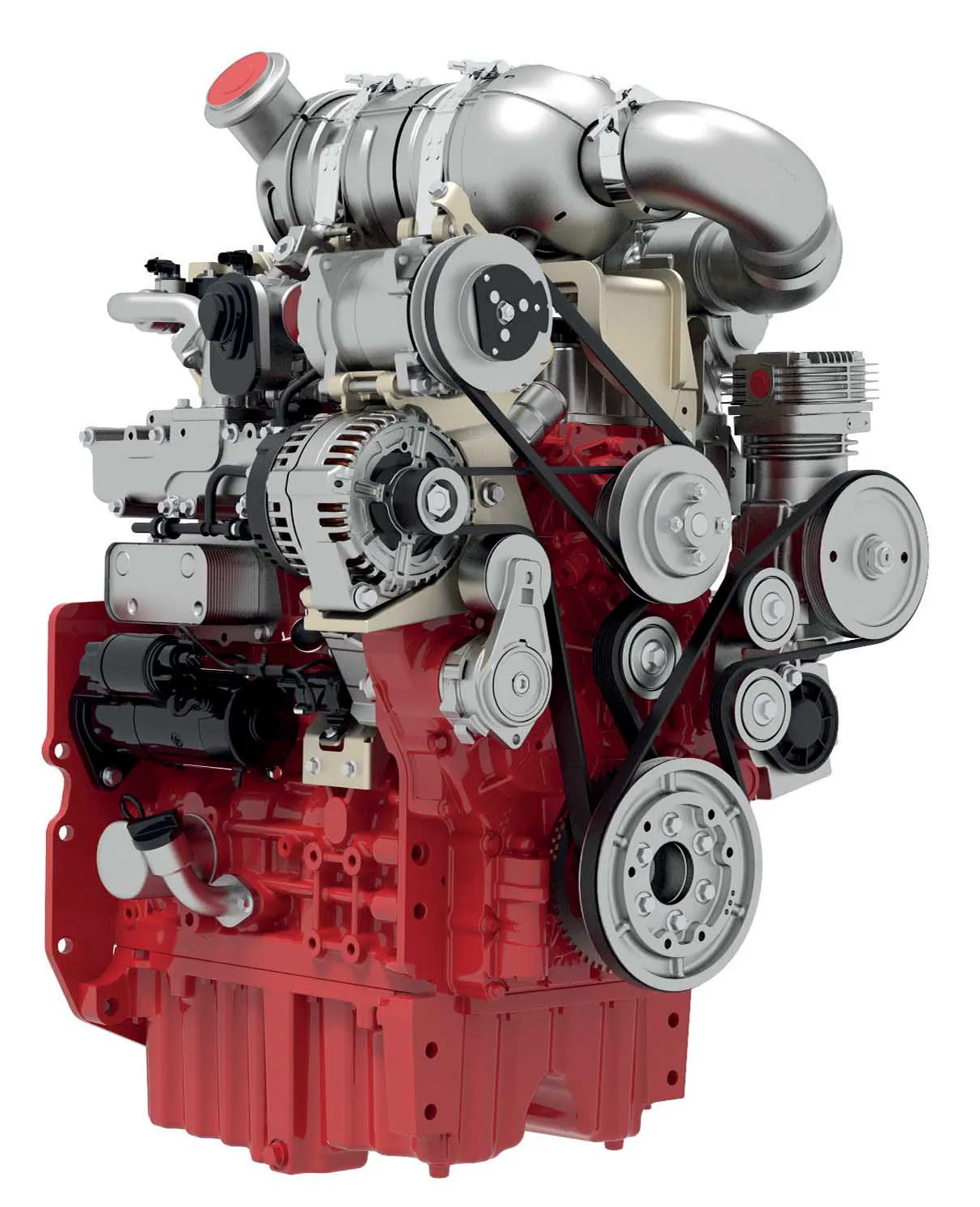

Caterpillar plans to open a new manufacturing facility in Xuzhou, Jiangsu Province, China, to produce undercarriage components and track assemblies, which are utilised on Cat hydraulic excavators.

April 5, 2012

Read time: 2 mins

Caterpillar plans to open a new manufacturing facility in Xuzhou, Jiangsu Province, China, to produce undercarriage components and track assemblies, which are utilised on Cat hydraulic excavators.

Construction and modifications to pre-existing buildings will start in 2011, with production scheduled for mid-2012."This new facility is our latest strategic investment to continue expanding our presence and capacity in the Asia/Pacific region.

Together with our joint venture, AsiaTrak in Tianjin, China, which also manufactures undercarriage components and track,

The 18,000m2 facility will be located in the Xuzhou Economic Development Zone, and when fully operational and at full capacity it is expected to employ about 400 people.

Caterpillar officials expect to realise a number of cost-saving benefits from the new facility, which will be located adjacent to the Caterpillar Xuzhou hydraulic excavator facility, allowing shipment of finished undercarriage components to the Caterpillar machine facility for final assembly.

"The investment in infrastructure and urbanisation forecasted in China's 12th Five-Year Plan should continue to drive long-term demand for construction equipment. This new facility, producing high-quality undercarriages for Cat excavators, further demonstrates our commitment to our customers' success, both in China and across the Asia/Pacific region," said Kevin Thieneman, Caterpillar country manager for China.