Caterpillar has introduced the next generation of articulated trucks, with the new B Series models, which now include the 735B, offering a 32.7tonne payload; the 740B (39.5tonnes), and the 740B EJ with ejector body (38tonnes).

February 16, 2012

Read time: 4 mins

The models are available with either Tier2/Stage2 equivalent or Tier 4 Interim/Stage IIIB certified emissions configurations to meet the needs of customers around the world.

Caterpillar says that both configurations feature revised transmission and traction control systems that enable higher productivity, while focusing on reducing driver effort and cutting operator fatigue through improved cab design.

The trucks will be available with Tier 4 Interim/Stage IIIB certified Cat diesel engines for those countries that require them. The systems employed on the trucks produce 90% less particulate matter (PM) and reduce nitrous oxides (NOx) emissions by as much as 50%.

"Caterpillar has further improved its six-wheel-drive system. A new, fully proportional torque-distribution automatic traction control (ATC) system eliminates the need for any driver intervention to maintain maximum traction in difficult operating conditions," says Caterpillar.

"The optimised proportional ATC system results in improved traction in all operating conditions for reduced cycle times and improved productivity. The automated system also reduces the possibility of system abuse, cutting wear and prolonging component life and reducing costs." Caterpillar also has upgraded its field-proven automatic transmission with the introduction of a number of significant technological improvements, meaning that gear changes are much smoother, as torque is maintained through each gear change, resulting in improved acceleration, especially on grades.

"The B Series trucks are designed and built around the operator. Behind the tough exterior, with its powerful new styling, integrated heavy-duty bumper and fully enclosed belly guards, the Cat truck offers the ideal operator environment. A new injection molded dash panel with revised trim provides an improved fit and a more aesthetically pleasing working environment." All B Series models are produced at Caterpillar's state-of-the-art production facility in Peterlee, UK.

The company is also introducing its latest motor grader models, the 140M2 and 160M2, along with their all-wheel-drive (AWD) counterparts, the 140M2 AWD and 160M2 AWD, are equipped with clean-burning, fuel-efficient engines meeting European Union Stage IIIB emission standards.

M Series 2 models are designed for a broad range of tasks, including heavy blade work, road maintenance, ripping and precision-finishing applications, and they use the Cat C9.3 ACERT engine with Variable Horse Power (VHP), offering a wider net variable-horsepower range than their M Series predecessors. The 140M2 and 160M2 have power ranges of 144kW to 181kW and 159kW to 196kW respectively.

Net power ratings for the 140M2 AWD and 160M2 AWD are 151kW to 181kW and 166kW to 196kW, respectively.

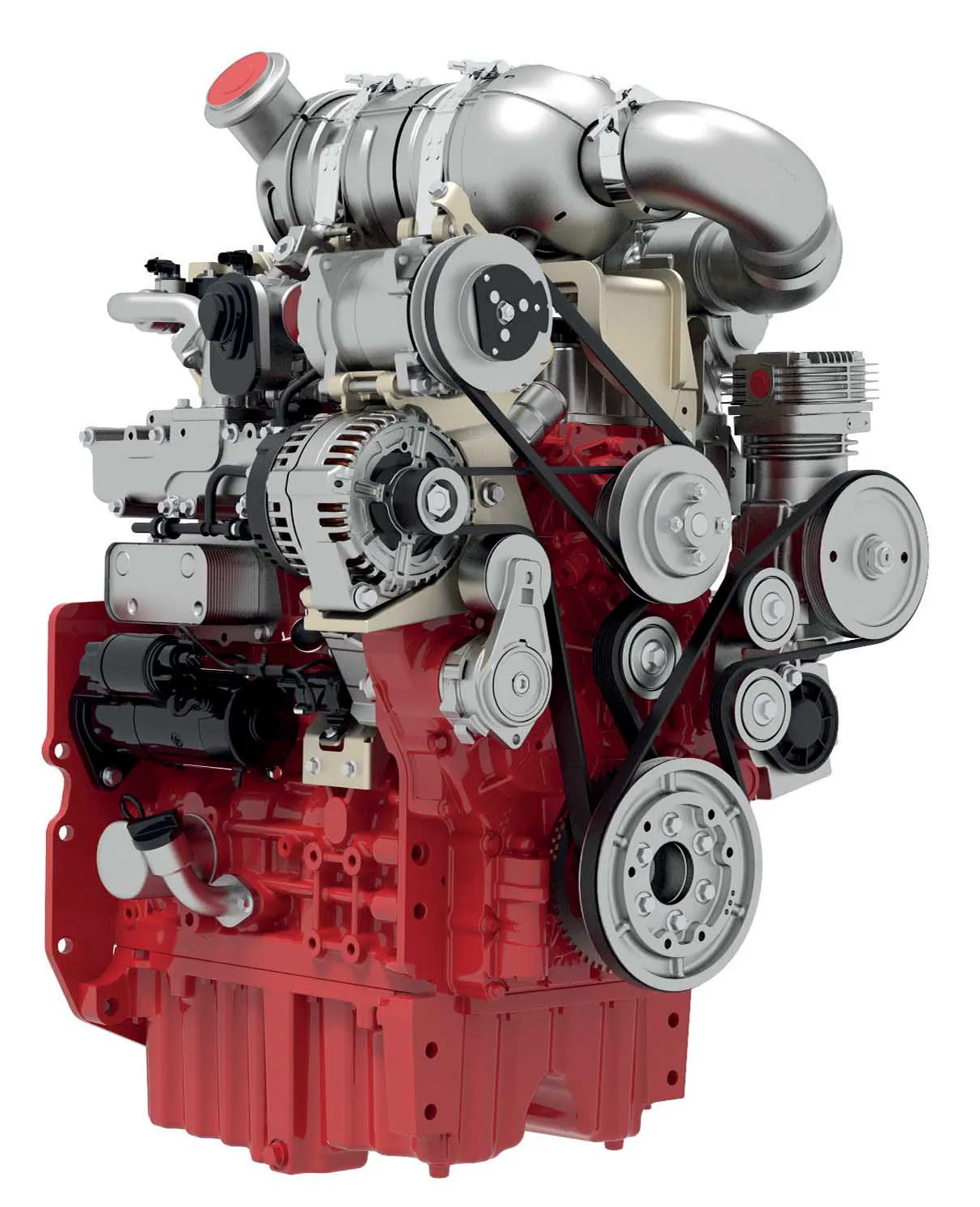

The C9.3 ACERT engine meets Stage IIIB emission standards utilising the building blocks of ACERT technology. The technology combines refined fuel, air-management and electronic systems with the Cat NOx-Reduction System and Cat Clean Emissions Module (CEM).

"At the heart of the M Series 2 design is the Cat control system, which uses two electronic joysticks to provide complete, precise control of the machine. The control system results in nearly 80% fewer hand and wrist movements compared to conventional motor grader controls: the net result is enhanced operator comfort and efficiency," says Caterpillar.

The M Series 2 models will also offer the new Cat Grade Control Cross Slope system, a complete machine control and guidance system which integrates traditional grade control with standard machine components at the factory.

This optional factory-installed and calibrated cross slope system provides automatic cross slope control capability, ready to operate from the moment it leaves the factory.

In addition, Cat Cross Slope is fully upgradeable and compatible with AccuGrade systems to grow with customers.

In addition to Cat Cross Slope, the M Series 2 motor graders will also continue to offer the AccuGrade Ready Option which provides all the mounting hardware, controls and harnesses for easy installation of all AccuGrade kits.