Quarry production shares many features worldwide. Mike Woof reports

Egyptian contractor

2414 Orascom has set up a new quarry site in the country's desert area, close to the city of Assuit. The quarry was opened specifically to supply Orascom's major road construction projects in this area of Egypt, with high quality aggregates.

At present Orascom is working on three separate highway construction projects that will link Assuit with capital Cairo to the north, the Red Sea to the east and Minya to the south. High quality stone from the quarry is used in the sub-base for the highways and is also used in the asphalt for the road surfacing, which is produced at Orascom's two

273 Marini batching plants that are located nearby. The firm also built the new civil/military

2545 Sohag Airport nearby, which is now open to air traffic and stone from the quarry was also used in the sub-base and asphalt for the runway, taxiway and road construction.

Although Orascom sold off its quarrying and cement operations to Lafarge some years ago the contractor realised it would need a facility to supply the road projects and airport construction with a steady supply of stone. Because of the comparatively short duration of these construction projects, Orascom decided it would be most logical to set-up and run its own operation.

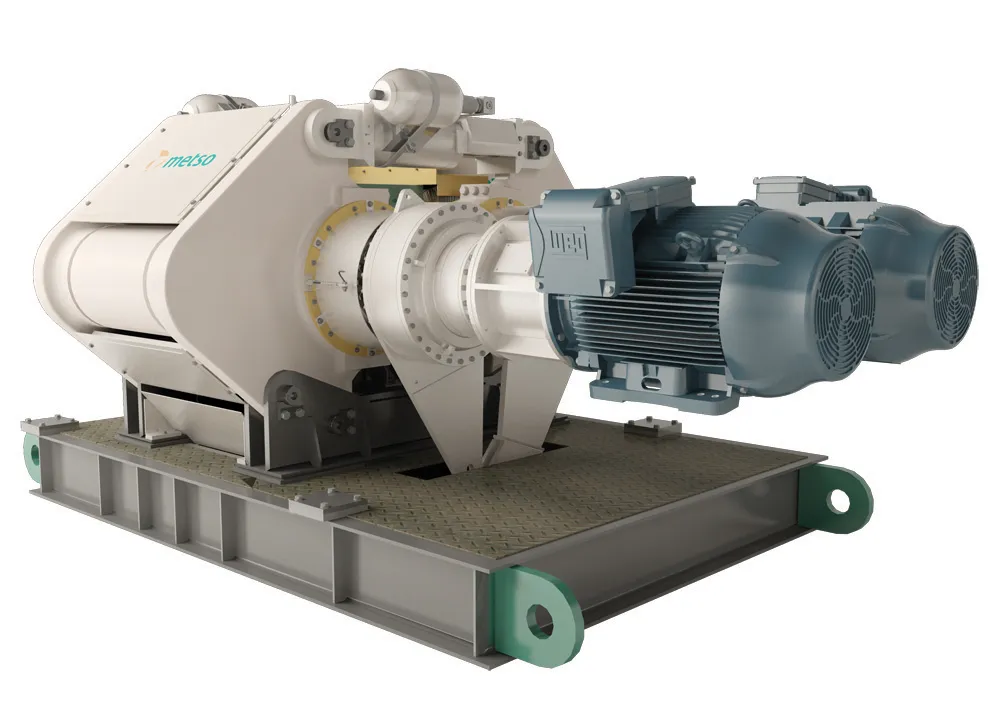

This quarry is equipped with the latest

6934 Metso crushing, screening and conveying equipment, allowing it to deliver around 300tonnes/hour. Material is extracted using ripping and primary breaking techniques rather than by blasting. The quarry has a fleet that includes a

178 Caterpillar D10N and a D9N dozer as well as a

2300 Komatsu D475-3 dozer for ripping work and uses three

233 Hitachi ZX380-3 excavators equipped with hammers for primary breaking. Extraction by ripping and primary breaking suits the geology and also suits Orascom's equipment fleet with its large number of dozers and the firm's operator experience. In addition this method reduces the need for security associated with explosives storage and also eliminates the risk of micro-cracking in the product that can lead to stone being crushed during compaction operations at a construction site.

The processing operation is based around a

6934 Metso C100 crusher, along with Metso equipment for screening and conveying, producing the four stone sizes need for Orascom's nearby construction projects. Four Caterpillar wheeled loaders are used for loading and stocking duties and these load the six on - off highway trucks that carry broken material to the crushing plant. Because the quarry is located at a remote spot in the desert and is some distance from a water supply, dust suppression presented a challenge. As a result Orascom built the quarry office some distance from the working area and operators stay in the cabs of their machines, while personnel minimise dust exposure by keeping away from the crushing and screening plant when it is in operation.