Sandvik Mining and Construction has signed an agreement with Bamtonnelstroy JSC covering the delivery of six LH 410 underground loaders (LHDs) featuring an innovative side-tipping bucket option. The loaders, being delivered in two lots, each have a capacity of up to 10tonnes and a bucket size of 4.6m³.

February 29, 2012

Read time: 2 mins

The loaders, being delivered in two lots, each have a capacity of up to 10tonnes and a bucket size of 4.6m³.

Bamtonnelstroy JSC is a pioneer in the use of cutting-edge Sandvik machinery equipped with a side-tipping bucket for underground construction in Russia.

The order will complete the full range of Sandvik equipment used by Bamtonnelstroy JSC in the construction of road and railway tunnels in Russia (these also include drill rigs, rock reinforcement machines and road headers).

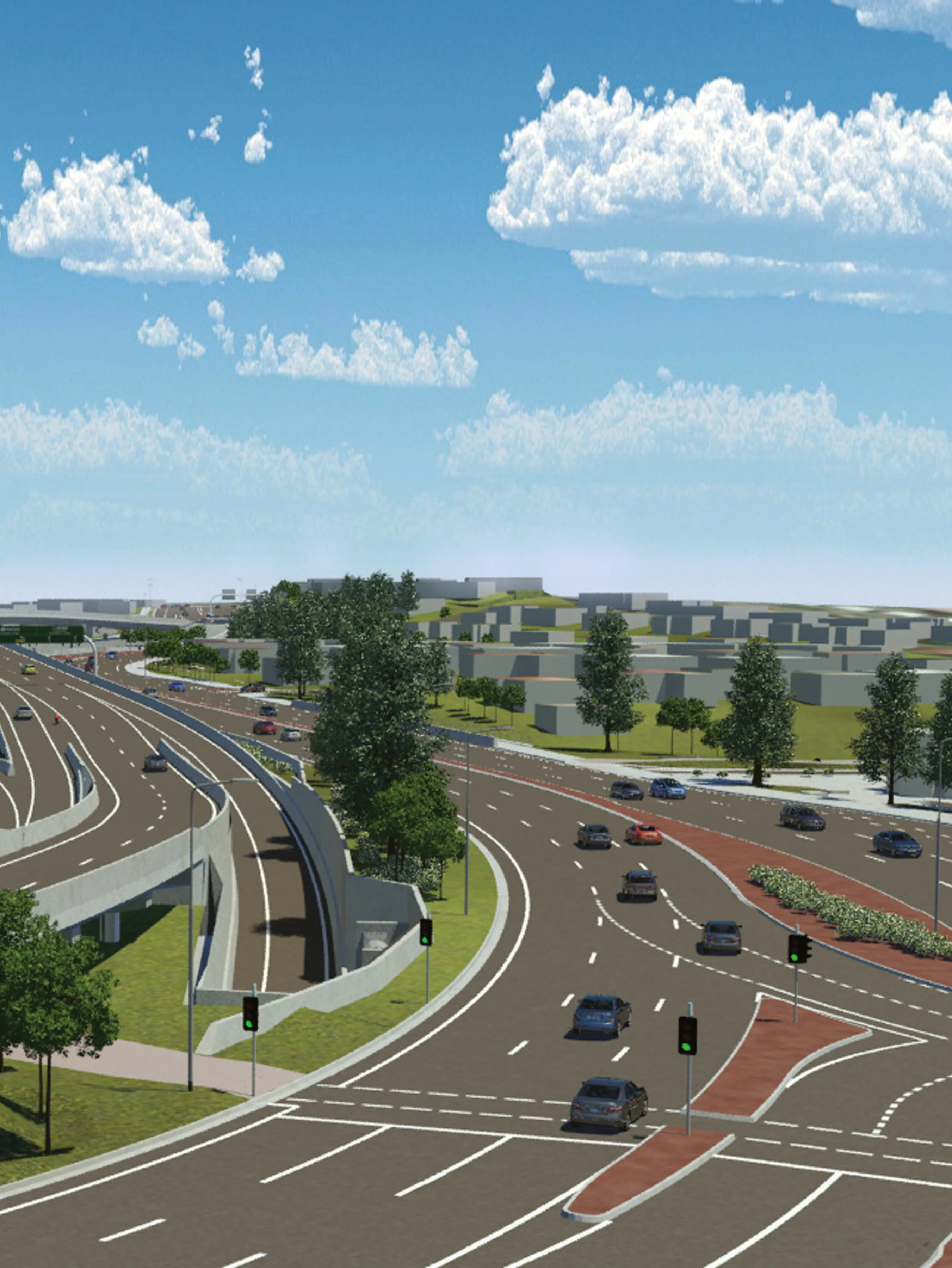

The company has the largest fleet of Sandvik machinery owned by a Russian company in the construction of underground facilities, and the loaders will be used primarily in the construction of tunnels for the new Adler-Roza Khutor highway, a vital link for the 2014 Winter Olympic Games being held at the Black Sea resort of Sochi. It will connect the Olympic Village and the Roza Khutor ski resort.

According to Sandvik the LH 410's fully automatic control system will reduce maintenance costs and save time in tunneling operations with the use of a side-tipping bucket reducing cost per tonne for transported rock mass.

"The equipment has proved its reliability and Sandvik tunnelling machines have enabled us to efficiently achieve our objectives within the adjusted time period," said Victor Balandin, chief engineer at Bamtonnelstroy JSC.