Sandvik is rolling out a range of sophisticated tunnelling jumbo drilling rigs, equipped with advanced automation features. The new DTi models feature wide coverage and powerful HX5T drifters that enable them to carry out large and small and tunnelling jobs. To optimise operation, the four machines can use Sandvik's latest iSURE software, which allows blasting operations to be designed on a PC and then downloaded onto the rigs using conventional USB memory sticks: this allows full automation of the face dri

July 20, 2012

Read time: 3 mins

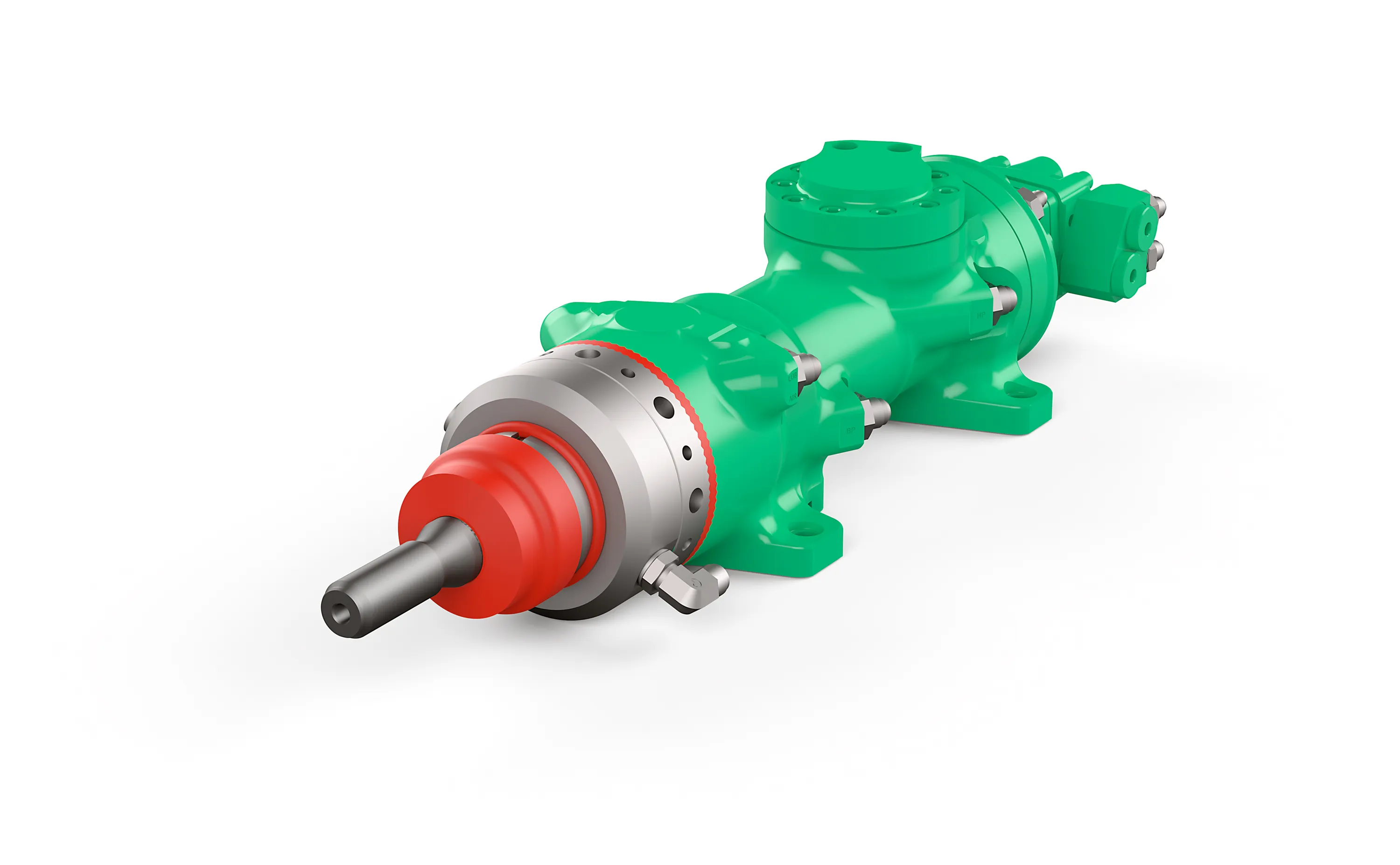

These new machines feature high comfort, air-conditioned cabs with ergonomically designed controls and graphical displays showing drill hole position. The benefits to the driller of the new rigs come in terms of high penetration rates and high accuracy drilling, thanks to the powerful 25kW H5XT rockdrills and precise hole spotting capabilities. Precision manufactured booms, feeds and hydraulics further increase accuracy. The controls and features of the machine all help to improve spotting and reduce hole deviation, which ensure more effective blasting and significantly reduce project costs overall.

The large cabs have up to 20% more glass than the previous models allowing better visibility of the working area, while high power xenon lights are fitted to illuminate the face. The drilling components are protected from damage, while maintenance access is from ground level. Servicing costs will be further reduced due to the installation of the latest machine health diagnostics tools. However, it is the advanced software technology that allows even an inexperienced driller to deliver the hole accuracy and quality of a highly skilled operator. According to Martti Keskinen, Development Manager at Finnish contractor

This is an important point, given that experienced drillers are hard to find and the high comfort cab is likely to help persuade new operators into using this machine.

Given that precise drilling bears such a large responsibility in terms of minimising tunnelling costs, it seems likely that the market will be receptive to such advanced technology. Lemminkäinen has been closely involved with the development of these new rigs and the contractor's feedback has played a large role in the final design of the machines (other tunnelling contractors have also played a role in this feedback process).

There are four models in the line-up at present, the DT920i, DT1120i, DT1130i and DT1230i. The DT920i and DT1120i are twin boom machines offering coverages of 16-125m² and 16-177m² respectively. The DT1130i and DT1230i are triple boom

machines with coverages of 20-177m² and 20-203m² respectively. All four rigs have an additional boom carrying an access platform, which can also be used for longhole drilling applications. Sandvik believes that these four rigs will comprehensively address the market for the drill and blast tunnelling sector. Meanwhile further models will be available for the extraction industries that use much of the same technology.