Veta 6 Released: Efficient, Comprehensive, and User-Friendly Intelligent Construction Data Analysis

Veta, developed by Transtec Group, is a free map-based intelligent construction data management software tool. It enables contractors and highway agencies to analyse and report data collected from intelligent compaction rollers and paver‐mounted thermal profilers (PMTP)/infrared (IR) scanners or cameras.

Transtec says that the new Veta 6 is the latest software release and features a host of improvements, allowing a more comprehensive viewing and analysis for intelligent construction data. Veta 6 enhances usability and expands upon features included with previous versions.

Starting with Veta 6, IC (compaction roller data) and PMTP data can be imported into one Veta project file. This allows for more efficient data viewing, analysis and reporting. Users need not switch back and forth between separate Veta files.

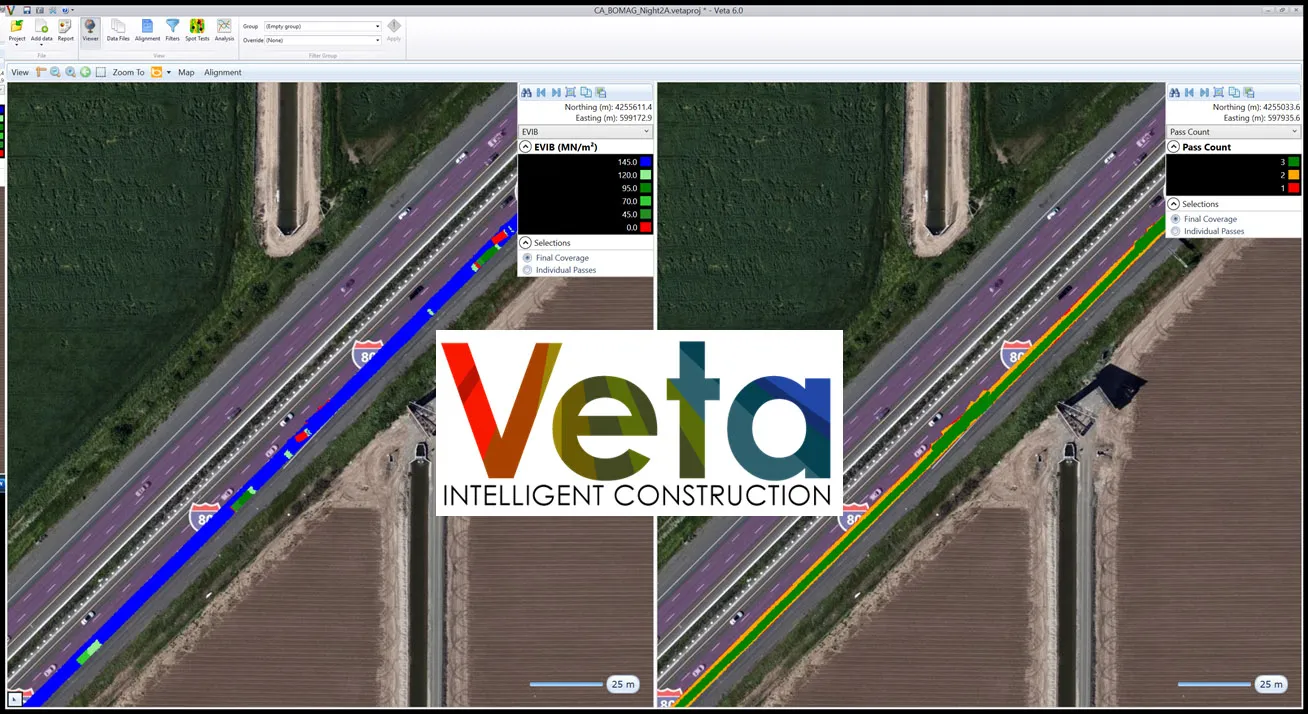

The new split-screen map options allow users to view up to four types of data simultaneously, including combinations of IC and PMTP data. With this feature, users can easily spot relationships and trends between data sets, says the company. The intuitive interface dramatically increases efficiency by minimising time spent hunting for correlating data among different files.

Veta 6 also includes more direct download support from vendor cloud platforms such as MOBA, TOPCON, Trimble, and Wirtgen/Vögele. Users of these platforms can download data from the cloud directly into Veta 6 and get to work immediately. Users no longer encounter data import compatibility issues. Direct download features also enhance data security to prevent data tampering.

There is an improved legend management system for customising and storing any legend with project specific properties. It can easily import saved legends into future projects to save time and resources. This innovation sets a precedent for all future legend systems implemented within geospatial information software, according to the company.

Reports now include “impacts per foot” as a new parameter, tical for ensuring optimum asphalt compaction.

The spot test screen in Veta 6 now allows for cut-and-pasting of spot tests for any roller pass. A user can include spot test data from nuclear density gauges on specific roller passes and core data on the final lift in one file and cut-and-paste them into Veta all at once. The ability to use spot tests and specific passes improves overall data analysis efficiency as well as shortens the time to identify discrepancies in data gathering.

Finally, Veta 6 features high-quality map backgrounds coupled with superior zoom options. Flying blind is never fun! The new high-quality map feature and the new overview “mini-map” will improve the user’s overall experience with Veta 6.

Transtec says that Veta is required in FHWA (the US Federal Highways Agency) AASHTO PP80, PP81 and MP39 specifications - and is increasingly adopted by highway authorities worldwide.

Transtec says that users and potential users will be given Veta training workshops if required.