Two Terex Trucks TR60 rigid dump trucks are proving their versatility at an Oman Cement Company (OCC) quarry in Muscat

OCC operates a quarry near the capital Muscat and issued a tender for two dump trucks.

Oman trading company Al Fairuz submitted a bid on behalf of Terex Trucks. And after visiting the job site, the team from Al Fairuz realised that the 55tonne capacity TR60 was well suited to the task at hand. Although the Terex Trucks brand is comparatively new to Oman, Al Fairuz was sure it could wi

October 26, 2016

Read time: 3 mins

Two Terex Trucks TR60 rigid dump trucks are proving their versatility at an Oman Cement Company (OCC) quarry in Muscat

OCC operates a quarry near the capital Muscat and issued a tender for two dump trucks.

Oman trading company Al Fairuz submitted a bid on behalf of8081 Terex Trucks. And after visiting the job site, the team from Al Fairuz realised that the 55tonne capacity TR60 was well suited to the task at hand. Although the Terex Trucks brand is comparatively new to Oman, Al Fairuz was sure it could win the supply deal.

Said to be well-suited to the application, the TR60s will clock up the hours quickly at OCC as the trucks will work three shifts/day. The machines will transport limestone, quartzophyllades, iron ore and kaolin from the quarry, and carry the blasted raw materials to the crusher. According to OCC, the machines will only have around only two hours off in 24 hours due to operator changeovers.

Al Fairuz took OCC personnel to the neighbouring UAE to see similar trucks in use. OCC then awarded the tender to Terex Trucks and put in an order for two TR60s.

Al Fairuz performed the pre-delivery inspection and invited staff from OCC to this so as to commence the training process before the trucks arrived on site. With the support of service engineers from Terex Trucks, training continued when the machines started in use. Al Fairuz spent two weeks on site at the quarry, providing further training for mechanics and operators.

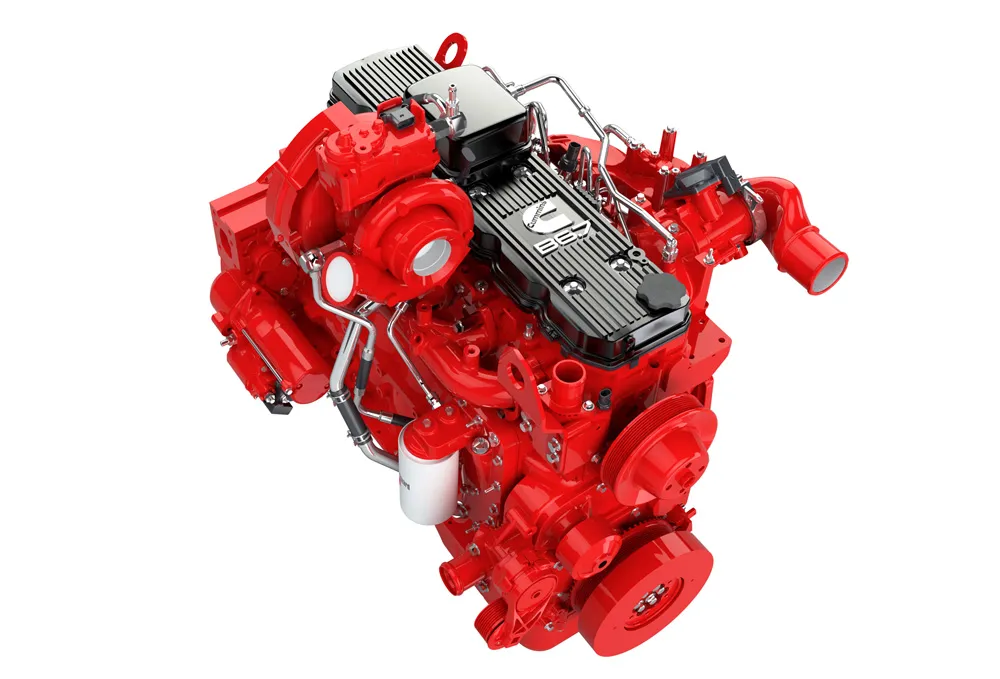

Established in 1978, OCC was set up as part of the regeneration project initiated by His Majesty Sultan Qaboos bin Said. Almost four decades on, the company now has three kilns and four cement mills with a capacity of 2.6 million tonnes/year and in the fourth quarter of 2015 OCC reported a net profit of US$12.2 million. The TR60 is fitted with a six-cylinder, 19litre diesel from Cummins that delivers 522kW and maximum torque of 2,981Nm. The machine has a drivetrain gear reduction that helps power the truck up steep inclines. Transmission and rear brake retardation systems comes as standard, while a high-capacity body with exhaust heating is said to ensure both material retention and cleaner dumping.

OCC operates a quarry near the capital Muscat and issued a tender for two dump trucks.

Oman trading company Al Fairuz submitted a bid on behalf of

Said to be well-suited to the application, the TR60s will clock up the hours quickly at OCC as the trucks will work three shifts/day. The machines will transport limestone, quartzophyllades, iron ore and kaolin from the quarry, and carry the blasted raw materials to the crusher. According to OCC, the machines will only have around only two hours off in 24 hours due to operator changeovers.

Al Fairuz took OCC personnel to the neighbouring UAE to see similar trucks in use. OCC then awarded the tender to Terex Trucks and put in an order for two TR60s.

Al Fairuz performed the pre-delivery inspection and invited staff from OCC to this so as to commence the training process before the trucks arrived on site. With the support of service engineers from Terex Trucks, training continued when the machines started in use. Al Fairuz spent two weeks on site at the quarry, providing further training for mechanics and operators.

Established in 1978, OCC was set up as part of the regeneration project initiated by His Majesty Sultan Qaboos bin Said. Almost four decades on, the company now has three kilns and four cement mills with a capacity of 2.6 million tonnes/year and in the fourth quarter of 2015 OCC reported a net profit of US$12.2 million. The TR60 is fitted with a six-cylinder, 19litre diesel from Cummins that delivers 522kW and maximum torque of 2,981Nm. The machine has a drivetrain gear reduction that helps power the truck up steep inclines. Transmission and rear brake retardation systems comes as standard, while a high-capacity body with exhaust heating is said to ensure both material retention and cleaner dumping.