Mining company Arcigrés has become the first Spanish buyer of New Holland Construction’s new W300C wheeled loader. Featuring New Holland’s Tier 4 interim AdBlue technology, the W300C was said to be chosen by the Valencia-based customer for its advanced performance, exceptional fuel efficiency, low emissions, and high productivity with fast cycles and 10tonne bucket capacity. A family business with over 30 years’ experience in the extraction of gravel, sand and china clay, Arcigrés purchased the W300C as pa

April 11, 2013

Read time: 2 mins

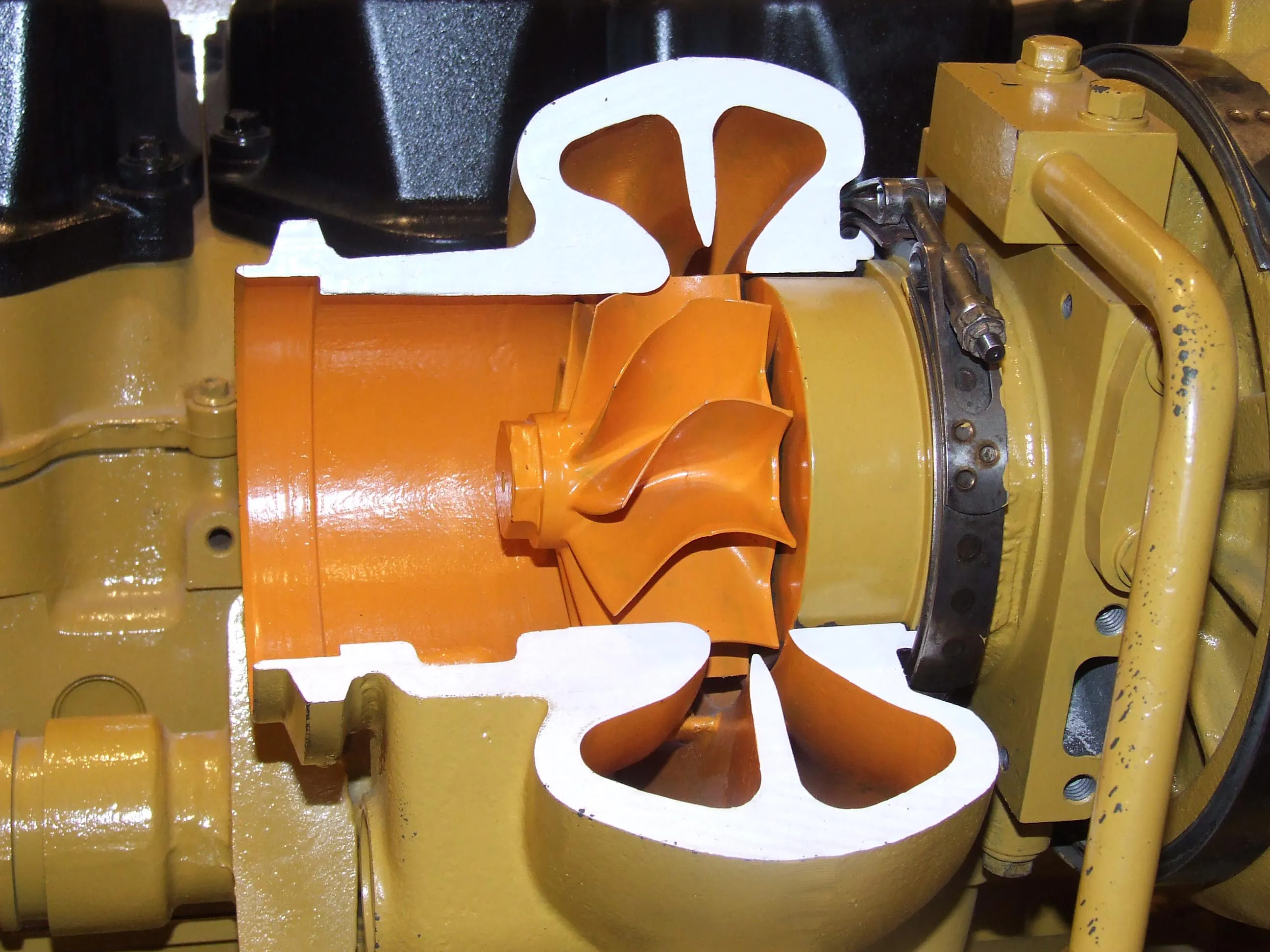

Mining company Arcigrés has become the first Spanish buyer of 5895 New Holland Construction’s new W300C wheeled loader.

Featuring New Holland’s Tier 4 interim4867 AdBlue technology, the W300C was said to be chosen by the Valencia-based customer for its advanced performance, exceptional fuel efficiency, low emissions, and high productivity with fast cycles and 10tonne bucket capacity.

A family business with over 30 years’ experience in the extraction of gravel, sand and china clay, Arcigrés purchased the W300C as part of its fleet renewal programme. At a time when the Spanish mining industry is in great difficulty, the company is said to be investing in updating its fleet to ensure it has high productivity equipment to run its operation efficiently.

A loyal New Holland Construction customer since the 1970s, Arcigrés is putting its new W300C machine to work in a quarry with a daily production of around 7,000m³, where about 2,000tonnes are loaded every day. The high capacity bucket, capable of carrying up to 10tonnes of china clay, drives up the W300C model’s productivity.

Jorge Gabarda Cortés, of Arcigrés, said he is delighted with its performance: “It’s wonderful. We load up a truck with just three buckets-full of clay!”

Featuring New Holland’s Tier 4 interim

A family business with over 30 years’ experience in the extraction of gravel, sand and china clay, Arcigrés purchased the W300C as part of its fleet renewal programme. At a time when the Spanish mining industry is in great difficulty, the company is said to be investing in updating its fleet to ensure it has high productivity equipment to run its operation efficiently.

A loyal New Holland Construction customer since the 1970s, Arcigrés is putting its new W300C machine to work in a quarry with a daily production of around 7,000m³, where about 2,000tonnes are loaded every day. The high capacity bucket, capable of carrying up to 10tonnes of china clay, drives up the W300C model’s productivity.

Jorge Gabarda Cortés, of Arcigrés, said he is delighted with its performance: “It’s wonderful. We load up a truck with just three buckets-full of clay!”