This software is a GNSS-based, 3D compaction control solution that makes operations more accurate, faster and easier. The package shares the same benefits as other Trimble Earthworks software tools already available for excavators, dozers and motor graders, which deliver improved productivity.

Trimble Earthworks for soil compactors enables contractors to control the compaction process accurately, reducing the risk of unnecessary passes that can result in over compaction. The platform makes the process more efficient, with a higher level of accuracy and less rework. As this package shares the same platform as other tools from the firm, contractors can benefit from shorter training times, reduced downtime and increased remote operator support in the field. In addition, users can benefit from ongoing platform developments as these become available.

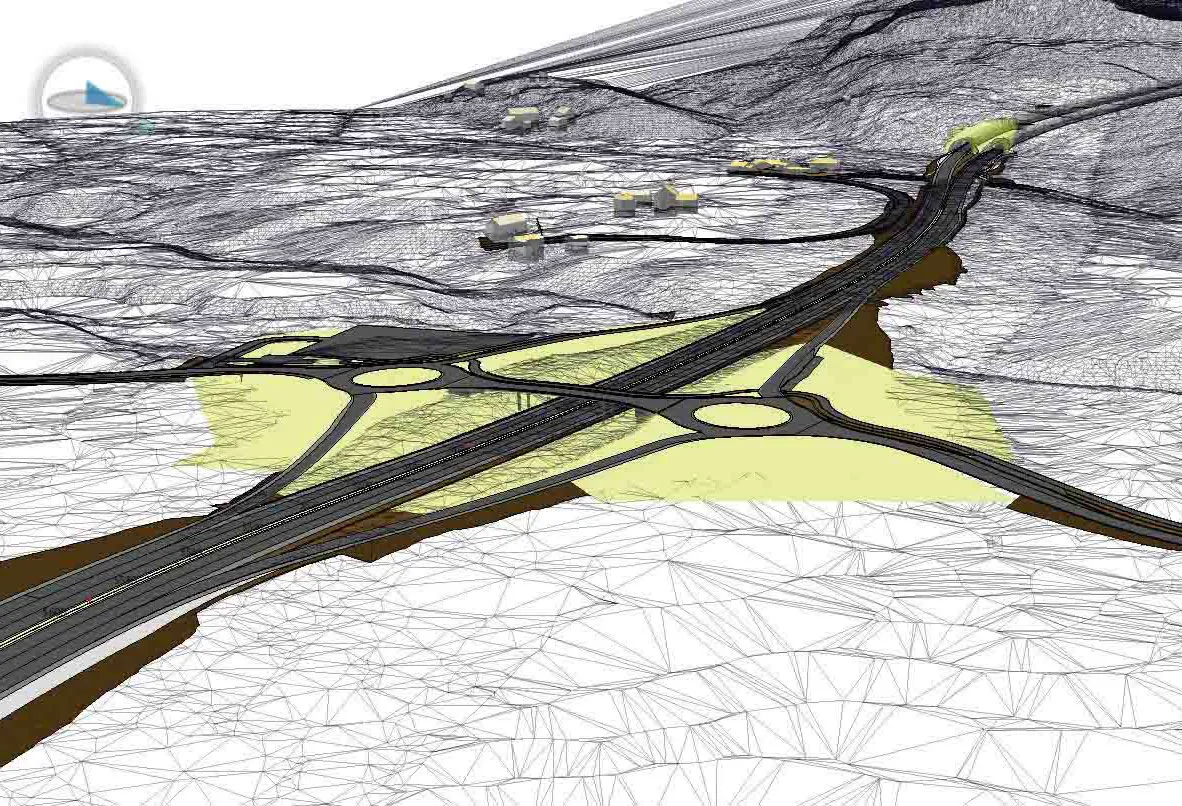

Improvements in material/surface lifts and layer management allow for accurate data and convenient data management. Office-to-field connectivity allows efficient communication and data transfer across the project. Contractors have ready access to productivity data collected from the machine allowing comparisons between work previously completed and work just carried out.

Trimble Earthworks for soil compactors features software licensing options at different pricing levels for budget conscious contractors. New infield design licenses for operators or 3D model-only licenses for increased functionality in the office make it possible for contractors to only pay for the features that they need.