The new Caterpillar 621H, 623H and 627H scrapers are said to deliver productivity and operator comfort and efficiency.

February 22, 2012

Read time: 2 mins

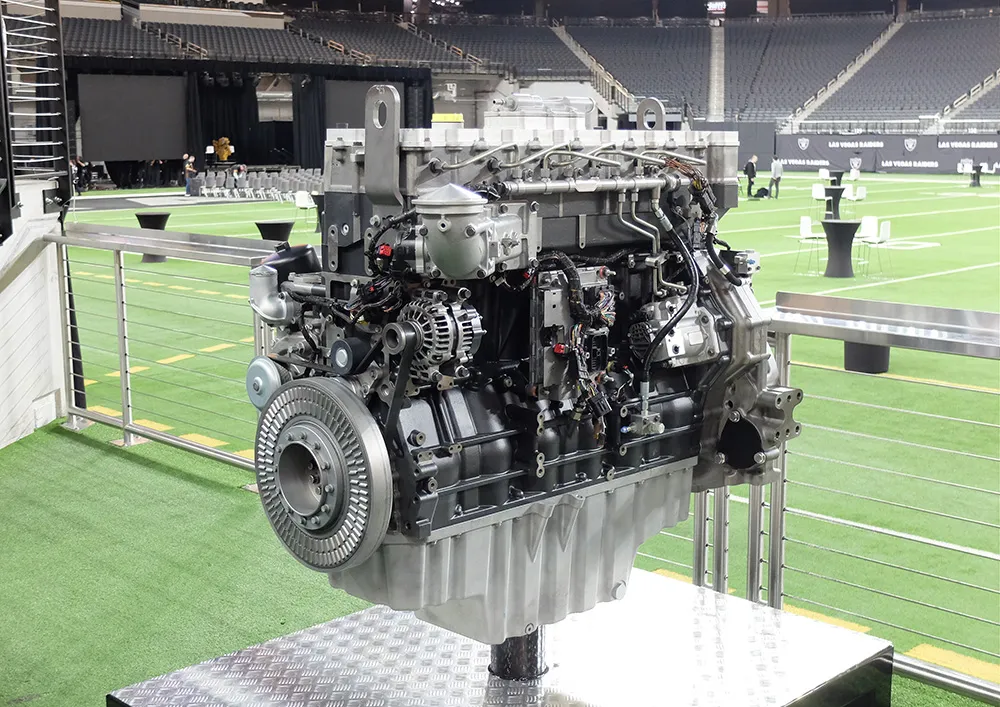

The new 178 Caterpillar 621H, 623H and 627H scrapers are said to deliver productivity and operator comfort and efficiency. Increased power and capacity, new structures, electronic controls and ergonomic design help increase capabilities and move material at lower cost/tonne. The machines come with the novel sequence assist and load assist tools that automate key tasks and when combined with Cat Grade Control, boost output. The 621H is offered in a push-pull configuration for the first time, allowing two scrapers to work together when loading. The new H Series machines replace the G Series machines and each of the three models is available with engines that meet US EPA Tier 4 Interim and EU Stage IIIB emissions standards as well as with engines for use in other regions. The 621H is a single-engine, open bowl machine; the 623H has an elevating scraper and a single engine; and the open-bowl 627H has twin engines, and all wheel drive. Capacities are increased by 1.5m3 ro 18.3m3 for the 621H and 627H. The new bowl design is easier to load than the G Series bowl and has proven to enhance production. The 623H bowl retains the17.6m3 capacity of the G Series, but the elevator is stronger and more powerful.

The new H Series scrapers feature more powerful engines and the Cat C13 engine in the tractor produces 304kW, 18% more power than the G Series. And the C9.3 on the 627H scraper produces 216 kW, an increase of 19% from the G Series. New software integrates engine and transmission. The system manages the torque converter and transmission to provide smooth operation. Performance on grades and coming out of the cut is said to be better. Caterpillar offers three new integrated technology options, with sequence assist available on all three models. This uses integrated software and position sensing cylinders to automate tasks when loading, hauling and dumping. The operator simply sets preferences for bowl and apron height and subsequently pushes a button to ready the machines for loading, then for hauling, then dumping, and then the return to the cut.

The system automatically sets the cushion hitch, bowl height, apron, ejector and elevator. Sequence Assist comes with a convenient load counter for tracking material moved. Load assist is available on the 621H and 627H models and as the machine enters the cut, the operator can activate the system which takes over control of the cutting edge height, limiting tyre spin based and ensuring consistent bowl loads. Cat grade control is available on all three models and works with the other automated features to maximise productivity.

The new H Series scrapers feature more powerful engines and the Cat C13 engine in the tractor produces 304kW, 18% more power than the G Series. And the C9.3 on the 627H scraper produces 216 kW, an increase of 19% from the G Series. New software integrates engine and transmission. The system manages the torque converter and transmission to provide smooth operation. Performance on grades and coming out of the cut is said to be better. Caterpillar offers three new integrated technology options, with sequence assist available on all three models. This uses integrated software and position sensing cylinders to automate tasks when loading, hauling and dumping. The operator simply sets preferences for bowl and apron height and subsequently pushes a button to ready the machines for loading, then for hauling, then dumping, and then the return to the cut.

The system automatically sets the cushion hitch, bowl height, apron, ejector and elevator. Sequence Assist comes with a convenient load counter for tracking material moved. Load assist is available on the 621H and 627H models and as the machine enters the cut, the operator can activate the system which takes over control of the cutting edge height, limiting tyre spin based and ensuring consistent bowl loads. Cat grade control is available on all three models and works with the other automated features to maximise productivity.