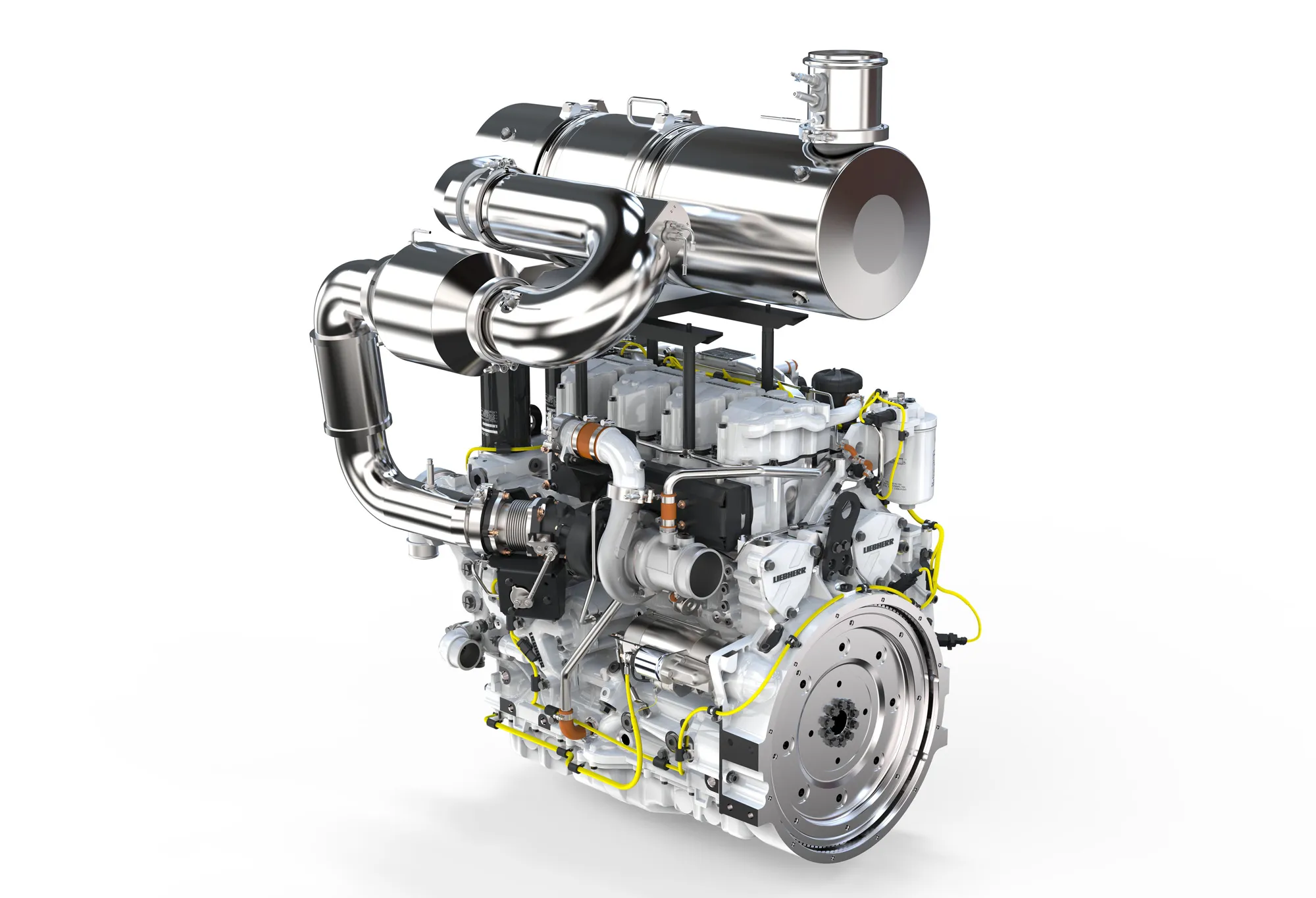

Liebherr has taken the wraps off the R960 demolition rig, a 93.5 tonne crawler with a choice of 28m and 34m boom configurations. A replacement for the previous R954C, the R960 is powered by a 240kW Stage IV diesel engine and features the latest Liebherr Demolition Control (LDC) active safety system.

January 6, 2017

Read time: 1 min