Morocco has a rapidly expanding road network, which is benefiting from expertise offered by French contractor Colas. The quality of Morocco's roads is higher than in many other African countries, with much of this due to the use of the latest road construction technology by Colas. It previously took almost two days to go from Casablanca to Tan Tan in the south and this journey now takes less than eight hours. Colas has some 800 machines and vehicles in Morocco, with 70 graders, 70 wheeled loaders, 50 excava

February 8, 2012

Read time: 2 mins

Morocco has a rapidly expanding road network, which is benefiting from expertise offered by French contractor 184 Colas. The quality of Morocco's roads is higher than in many other African countries, with much of this due to the use of the latest road construction technology by Colas.

It previously took almost two days to go from Casablanca to Tan Tan in the south and this journey now takes less than eight hours. Colas has some 800 machines and vehicles in Morocco, with 70 graders, 70 wheeled loaders, 50 excavators, 50 compactors, 30 bulldozers, six articulated haulers and a lot of smaller vehicles.2394 Volvo supplies 30 of these larger machines, including G900 graders, L120F wheel loaders, excavators of 22-45tonnes and a dozen asphalt pavers including Volvo's latest ABG7820 paver. Colas has doubled its business in Morocco over the last five years, benefiting from increased government spending on its road network.

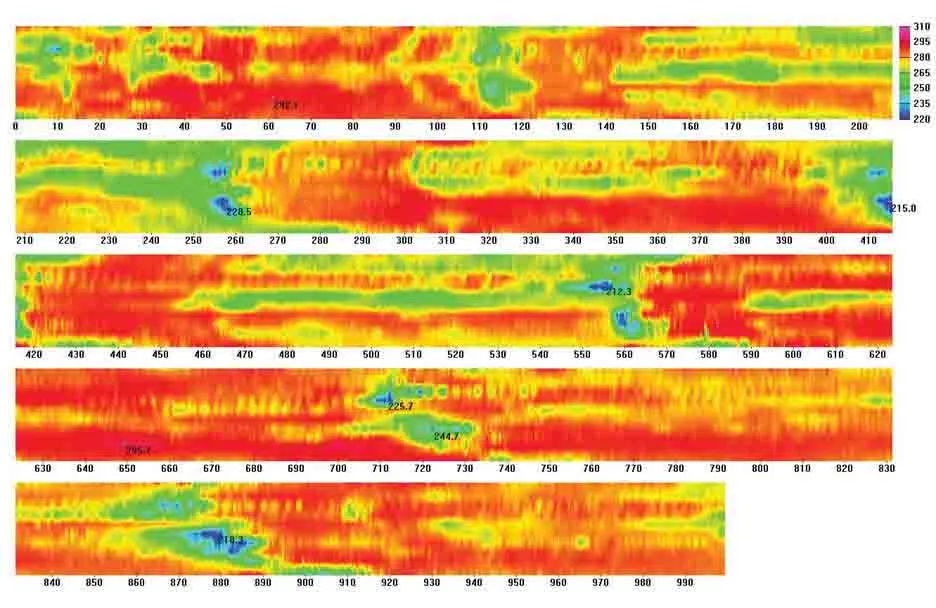

However, harsh conditions make building roads in desert conditions difficult. The heat affects the wearing course, but this can be solved using admixtures to the asphalt, however the occasional rainstorm breaks up the structure and can be heavy and destructive. Meanwhile traffic volumes have grown significantly and the country has had to develop its network significantly. With contracts to build 150km of highway near Morocco's border with Mauritania, a 40km road through the mountains near Casablanca and a host of other projects, Colas hopes to win more business in the future.

It previously took almost two days to go from Casablanca to Tan Tan in the south and this journey now takes less than eight hours. Colas has some 800 machines and vehicles in Morocco, with 70 graders, 70 wheeled loaders, 50 excavators, 50 compactors, 30 bulldozers, six articulated haulers and a lot of smaller vehicles.

However, harsh conditions make building roads in desert conditions difficult. The heat affects the wearing course, but this can be solved using admixtures to the asphalt, however the occasional rainstorm breaks up the structure and can be heavy and destructive. Meanwhile traffic volumes have grown significantly and the country has had to develop its network significantly. With contracts to build 150km of highway near Morocco's border with Mauritania, a 40km road through the mountains near Casablanca and a host of other projects, Colas hopes to win more business in the future.