New Holland Construction launched the first two models of its new C Series range of crawler excavators at the recent Samoter event in Italy. With operating weights ranging from 27-31tonnes, the new E265C and E305C models introduce new features that that are said to improve productivity and performance, and these include Tier 4 interim engines delivering more power and up to 10% improvement in fuel efficiency; high efficiency hydraulic system to increase productivity by up to 10%; EVO cab with ROPS/FOPS prot

February 13, 2012

Read time: 2 mins

With operating weights ranging from 27-31tonnes, the new E265C and E305C models introduce new features that that are said to improve productivity and performance, and these include Tier 4 interim engines delivering more power and up to 10% improvement in fuel efficiency; high efficiency hydraulic system to increase productivity by up to 10%; EVO cab with ROPS/FOPS protection (its new dampers cut vibrations by 30% when travelling and up to 50% when digging) and new joystick controls offering more comfort and safety, and heavy duty design with reinforced undercarriage.

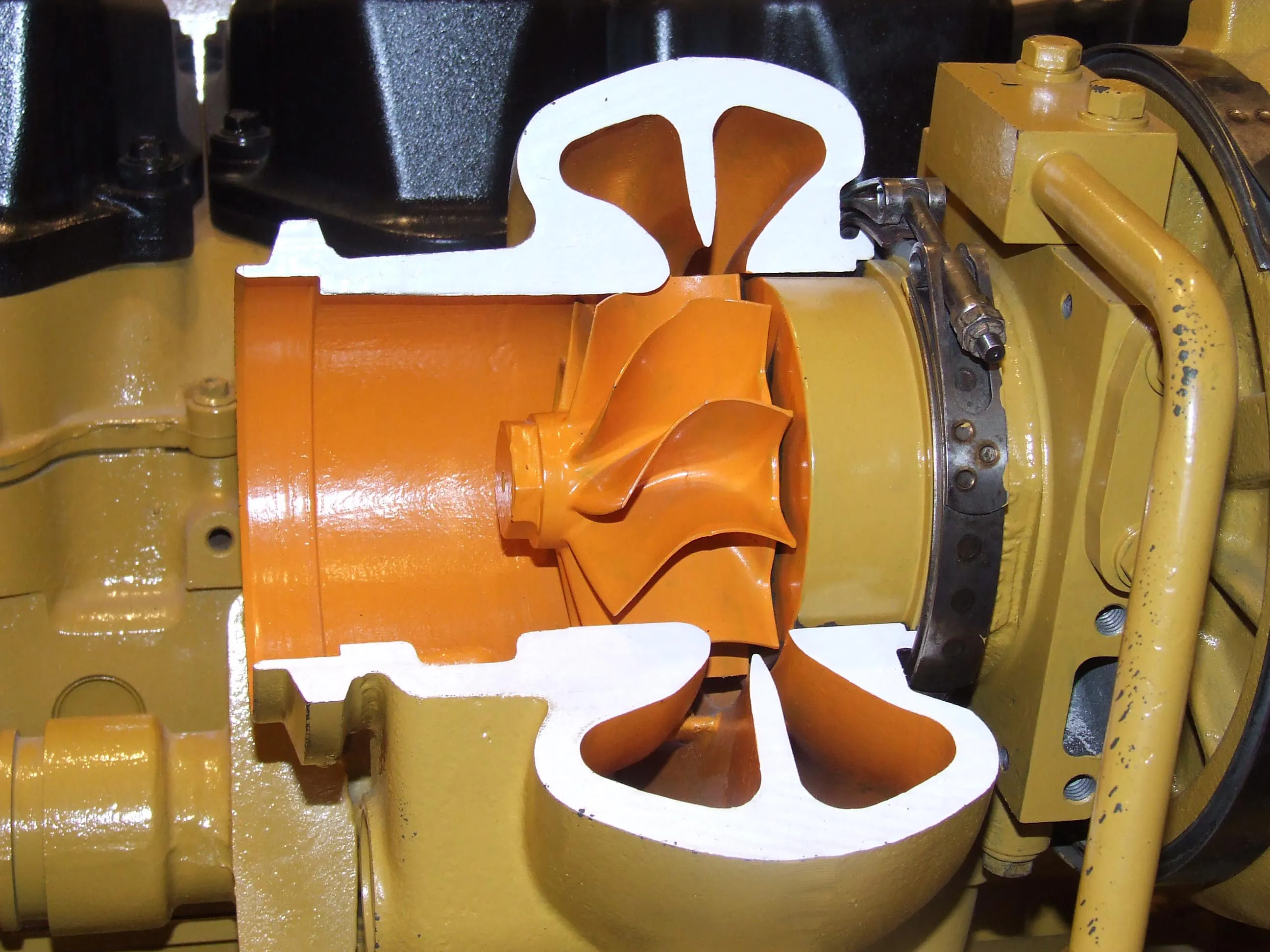

Both models feature New Holland's Selective Catalytic Reduction (SCR) technology to meet Tier 4 interim emissions requirements. This solution, developed by FPT Industrial, relies on an after-treatment system that breaks down the NOx into nitrogen and water through a chemical reaction with a diesel exhaust fluid (DEF), which is marketed under the AdBlue registered name in Europe. The combustion process is optimised to reduce particulate matter (PM), so that no particulate filter is required. The SCR system is fully integrated into the design of the excavator.

"A complete re-design of the hydraulic system, encompassing the main pumps, spool, solenoid and return valves, has significantly increased the machines' controllability and hydraulic efficiency," says New Holland Construction.

The introduction of a new ECO operating mode further enhances the engines' fuel economy, reducing fuel consumption by 10% compared to the B Series.

The E265C and E305C have gross rated output power of 142kW and 152kW, and bucket capacities of 0.58-1.40m³ and 0.6-1.65m³.