With the launch of the PW168-11 and PW198-11, Komatsu reports it has rounded up the operating weights of its wheeled excavator range to 20 tonnes.

Komatsu says that the new machines - at 16 and 20 tonnes - are compact and easy to transport yet powerful and versatile.

There is no need for a special low-bed trailer. With a low transportation height of just 3.1m, they can be transported on standard low-bed trailers with a loading height of up to 4m. The short rear overhang of 1.85m (PW168-11) or 1.9m (PW198-11) is ideal for narrow construction sites.

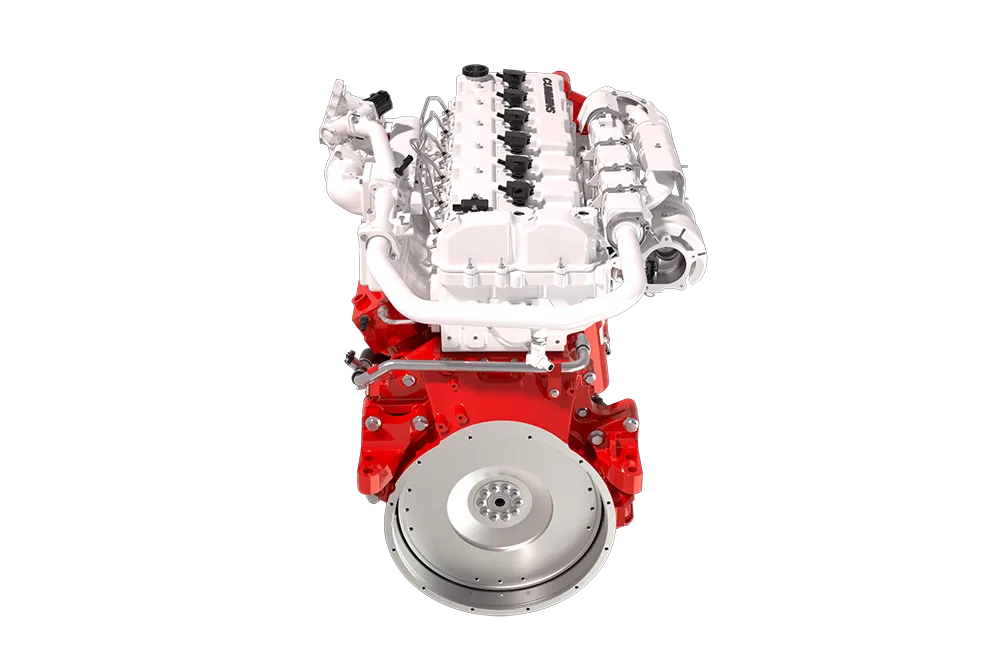

The units are equipped with 4-cylinder Komatsu 110kW and 129kW diesel engines are EU Stage V emissions compliant and factory-supplied with environmentally friendly HVO Diesel fuel as standard. The machine design with an optimised boom and rear engine enables enormous lifting performance.

Thanks to a low centre of gravity, the machines are stable when driven on any road. The new premium seat with multi-stage ventilation and seat heating is particularly comfortable. All-important functions can be operated via joysticks while the all-round visibility is supported by four cameras with a bird's eye view as standard.

Komatsu notes that contractors are increasingly using a tiltrotator and 3D guidance systems on wheeled excavators. Because of this, the company’s new models are open to any kind of system and are prepared for use with a tiltrotator as well as for 3D guidance systems. With useful extras such as joystick steering, tool control management or trailer coupling, the PW168 and PW198 can be optimally prepared for tough construction sites.

The new Komatsu diesel particle filters, which are replaced after only 8,000 hours, enable long and uninterrupted work schedules. Exhaust gas treatment is carried out fully automatically, without disrupting workflow. All maintenance points are centralised and easily accessible from ground level behind steel flaps.

All important functions are displayed as standard via the machine monitor and the Komtrax fleet management system.