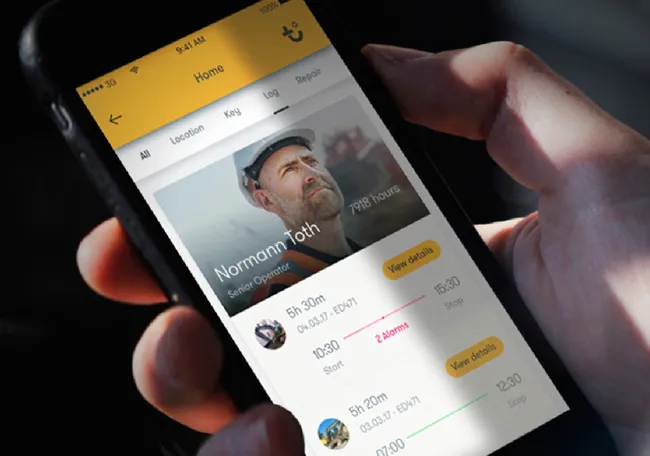

The new Trackunit tool is said to allow fleet operators to monitor machine health. This novel smartphone app can link operators and equipment. An advanced version of the Trackunit On smartphone app, the new tool means that equipment rental companies and fleet owners can stay on top of machine and operator health.

The system is said to provide a smart solution to log and track start-up routines together with service and maintenance requirements. Trackunit On provides a smartphone-driven checklist so operato

September 28, 2018

Read time: 1 min

The new Trackunit tool is said to allow fleet operators to monitor machine health. This novel smartphone app can link operators and equipment. An advanced version of the Trackunit On smartphone app, the new tool means that equipment rental companies and fleet owners can stay on top of machine and operator health.

The system is said to provide a smart solution to log and track start-up routines together with service and maintenance requirements. Trackunit On provides a smartphone-driven checklist so operators can ensure equipment passes pre-checks, service requirements are up to date, and submit reports of visual damage, including providing photographic evidence. For rental companies Trackunit can be a tool for making pre-checks before rented equipment is handed over, and final checks when equipment is returned.