The UK drainage and maintenance specialist Lanes Group has helped deliver the new A453 dual-carriageway in the county of Nottinghamshire, one of England’s worst congestion areas.

Main contractor Laing O'Rourke managed the two-and-a-half-year project that included the widened commuter route from Junction 24 of the M1 motorway to the A52 highway in Nottingham city centre at a cost of US$265 million.

The new road - named Remembrance Way in honour of the 453 British soldiers who lost their lives in Afgha

October 16, 2015

Read time: 2 mins

The UK drainage and maintenance specialist 7891 Lanes Group has helped deliver the new A453 dual-carriageway in the county of Nottinghamshire, one of England’s worst congestion areas.

Main contractor Laing O'Rourke managed the two-and-a-half-year project that included the widened commuter route from Junction 24 of the M1 motorway to the A52 highway in Nottingham city centre at a cost of US$265 million.

The new road - named Remembrance Way in honour of the 453 British soldiers who lost their lives in Afghanistan - opened in July.

Services provides by Lanes Group's depot in the city of Derby, included CCTV drainage surveys, drainage jetting, specialist cutting services, patch lining and pipe-deformity repair.

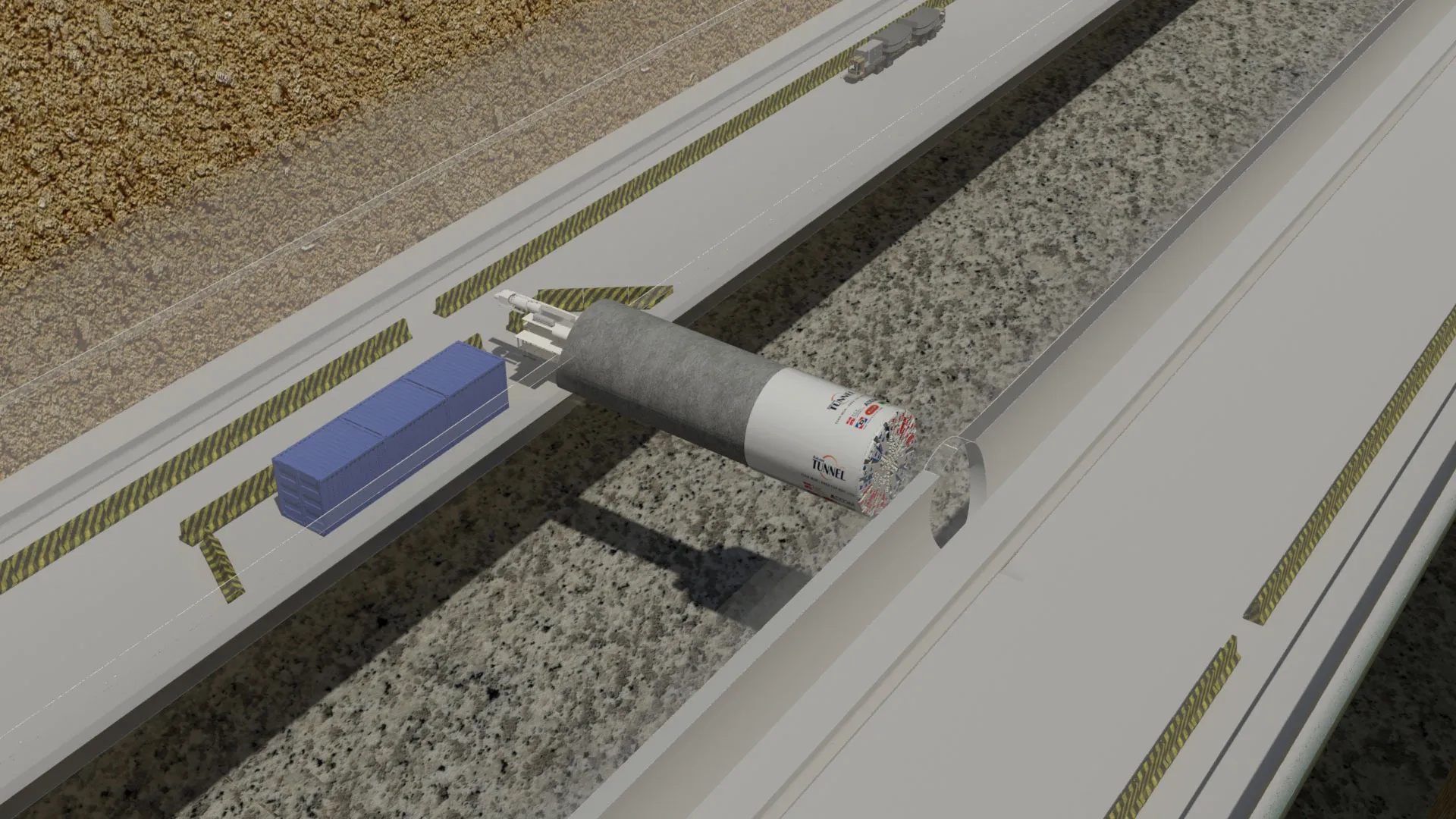

In one case, a CCTV survey found deformation of a 300mm diameter surface water pipe, 25m from the manhole access point and beneath a newly-laid roadway.

Laing O'Rourke considered the option of excavating the new roadway to replace the faulty pipe. However, Lanes was able to cut out the deformed inner wall of the plastic pipe and reline the section.

“We provided just about every service in our repertoire to support this scheme,” said Chris Norbury, area development manager for Lanes Derby. "We're delighted that, at key moments, our specialist expertise has made the difference in terms of resolving important drainage issues."

"On a number of occasions their specialist expertise has provided solutions that have saved us time and money,” said Laing O'Rourke civil engineer Joseph Maltezos.

A sub-contractor had mistakenly driven a spike through a drainage line. Lanes used a specialist cutter to remove it and patch line in the hole - avoiding a costly excavation.

Main contractor Laing O'Rourke managed the two-and-a-half-year project that included the widened commuter route from Junction 24 of the M1 motorway to the A52 highway in Nottingham city centre at a cost of US$265 million.

The new road - named Remembrance Way in honour of the 453 British soldiers who lost their lives in Afghanistan - opened in July.

Services provides by Lanes Group's depot in the city of Derby, included CCTV drainage surveys, drainage jetting, specialist cutting services, patch lining and pipe-deformity repair.

In one case, a CCTV survey found deformation of a 300mm diameter surface water pipe, 25m from the manhole access point and beneath a newly-laid roadway.

Laing O'Rourke considered the option of excavating the new roadway to replace the faulty pipe. However, Lanes was able to cut out the deformed inner wall of the plastic pipe and reline the section.

“We provided just about every service in our repertoire to support this scheme,” said Chris Norbury, area development manager for Lanes Derby. "We're delighted that, at key moments, our specialist expertise has made the difference in terms of resolving important drainage issues."

"On a number of occasions their specialist expertise has provided solutions that have saved us time and money,” said Laing O'Rourke civil engineer Joseph Maltezos.

A sub-contractor had mistakenly driven a spike through a drainage line. Lanes used a specialist cutter to remove it and patch line in the hole - avoiding a costly excavation.