German loader manufacturer Kramer-Werke has revised its products as part of a rebrand programme. The Kramer brand now stands alone, without the addition of allwheel.

As part of the rebrand, Kramer has adapted machine names to indicate size classes for its economy 5 Series and premium 8 Series products. For example, 8095T stands for a Series 8 product with a bucket capacity of 0.95m3 and the T stands for tele wheel loader.

The new wheeled loader models of the 5 Series, 5075, 5085, 5085T and 5095 with

January 12, 2015

Read time: 2 mins

German loader manufacturer 4849 Kramer Allrad has revised its products as part of a rebrand programme. The Kramer brand now stands alone, without the addition of allwheel.

As part of the rebrand, Kramer has adapted machine names to indicate size classes for its economy 5 Series and premium 8 Series products. For example, 8095T stands for a Series 8 product with a bucket capacity of 0.95m3 and the T stands for tele wheel loader.

The new wheeled loader models of the 5 Series, 5075, 5085, 5085T and 5095 with bucket sizes from 0.75-0.95m3 have been completely revised, including the cab, engine and powertrain.

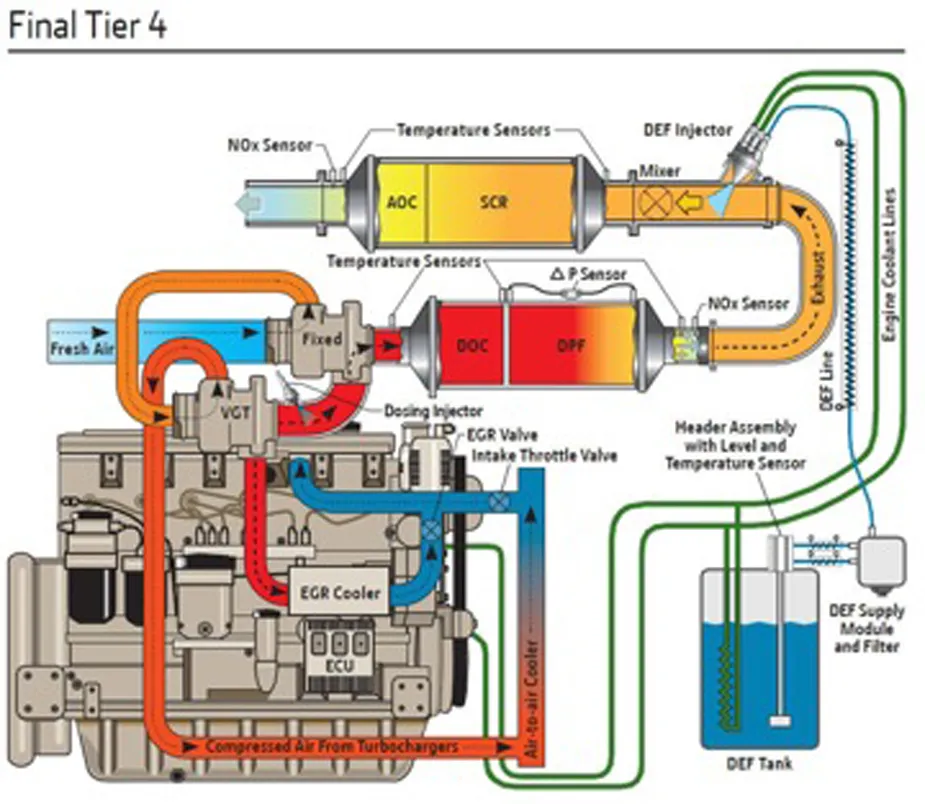

The central component of the larger models 5085T and 5095 is a charge air-cooled 4-cylinder turbo engine with 55kW. Torque has been increased by up to 17%. Kramer said thanks to the maintenance-free diesel oxidation catalyst (DOC) there is no downtime. Compared to technology with diesel particulate filters (DPF), DOC needs no active open burning. DOC also reduces fuel consumption.

The cabins have a multi-function joystick, hand throttle, low-speed control and load stabiliser. The larger wheeled loaders from the 5075 model upwards also have three steering options: all-wheel, front-wheel and crab steering.

The Premium 8 Series - formerly the 80 series - features the seven wheeled loader models from 8075 to 8115. Wheeled loader 8075 has a 35kW7139 Yanmar engine that meets emission Stage 3A standard.

The other six wheeled loader and tele wheel loader models 8085, 8085T, 8095, 8095T, 8105 and 8115 are equipped as standard with the 55kW201 Deutz engine TCD 2.9. The exhaust aftertreatment takes place via the DOC technique. Larger models in the series, such as the wheeled- and tele-wheel loaders 8105, 8115 and 8095T, have the option of a 75kW engine.

Also optional for all of the 8-series models is the Powerflow high-performance hydraulic system. This allows operation of powerful hydraulic attachments such as asphalt mills or rotary snow ploughs.

As part of the rebrand, Kramer has adapted machine names to indicate size classes for its economy 5 Series and premium 8 Series products. For example, 8095T stands for a Series 8 product with a bucket capacity of 0.95m3 and the T stands for tele wheel loader.

The new wheeled loader models of the 5 Series, 5075, 5085, 5085T and 5095 with bucket sizes from 0.75-0.95m3 have been completely revised, including the cab, engine and powertrain.

The central component of the larger models 5085T and 5095 is a charge air-cooled 4-cylinder turbo engine with 55kW. Torque has been increased by up to 17%. Kramer said thanks to the maintenance-free diesel oxidation catalyst (DOC) there is no downtime. Compared to technology with diesel particulate filters (DPF), DOC needs no active open burning. DOC also reduces fuel consumption.

The cabins have a multi-function joystick, hand throttle, low-speed control and load stabiliser. The larger wheeled loaders from the 5075 model upwards also have three steering options: all-wheel, front-wheel and crab steering.

The Premium 8 Series - formerly the 80 series - features the seven wheeled loader models from 8075 to 8115. Wheeled loader 8075 has a 35kW

The other six wheeled loader and tele wheel loader models 8085, 8085T, 8095, 8095T, 8105 and 8115 are equipped as standard with the 55kW

Also optional for all of the 8-series models is the Powerflow high-performance hydraulic system. This allows operation of powerful hydraulic attachments such as asphalt mills or rotary snow ploughs.