Komatsu is introducing its new WA270-8 wheeled loader, which is designed as a versatile performer that can handle a wide range of duties.

A key feature for this versatility is its quick coupler, which allows a wide range of attachments to be fitted. Power comes from a Tier 4 Final/Stage IV emissions compliant engine, which offers a fuel saving of up to 3% over the model being replaced. The firm claims that the machine offers high stability, breakout power and tractive effort. It has a parallel-lift linka

April 5, 2017

Read time: 2 mins

Komatsu is introducing its new WA270-8 wheeled loader, which is designed as a versatile performer that can handle a wide range of duties.

A key feature for this versatility is its quick coupler, which allows a wide range of attachments to be fitted. Power comes from a Tier 4 Final/Stage IV emissions compliant engine, which offers a fuel saving of up to 3% over the model being replaced. The firm claims that the machine offers high stability, breakout power and tractive effort. It has a parallel-lift linkage, with auto tilt-in to simulate a Z-bar, which can be used in a wide array of applications, from pallet handling to hard digging.

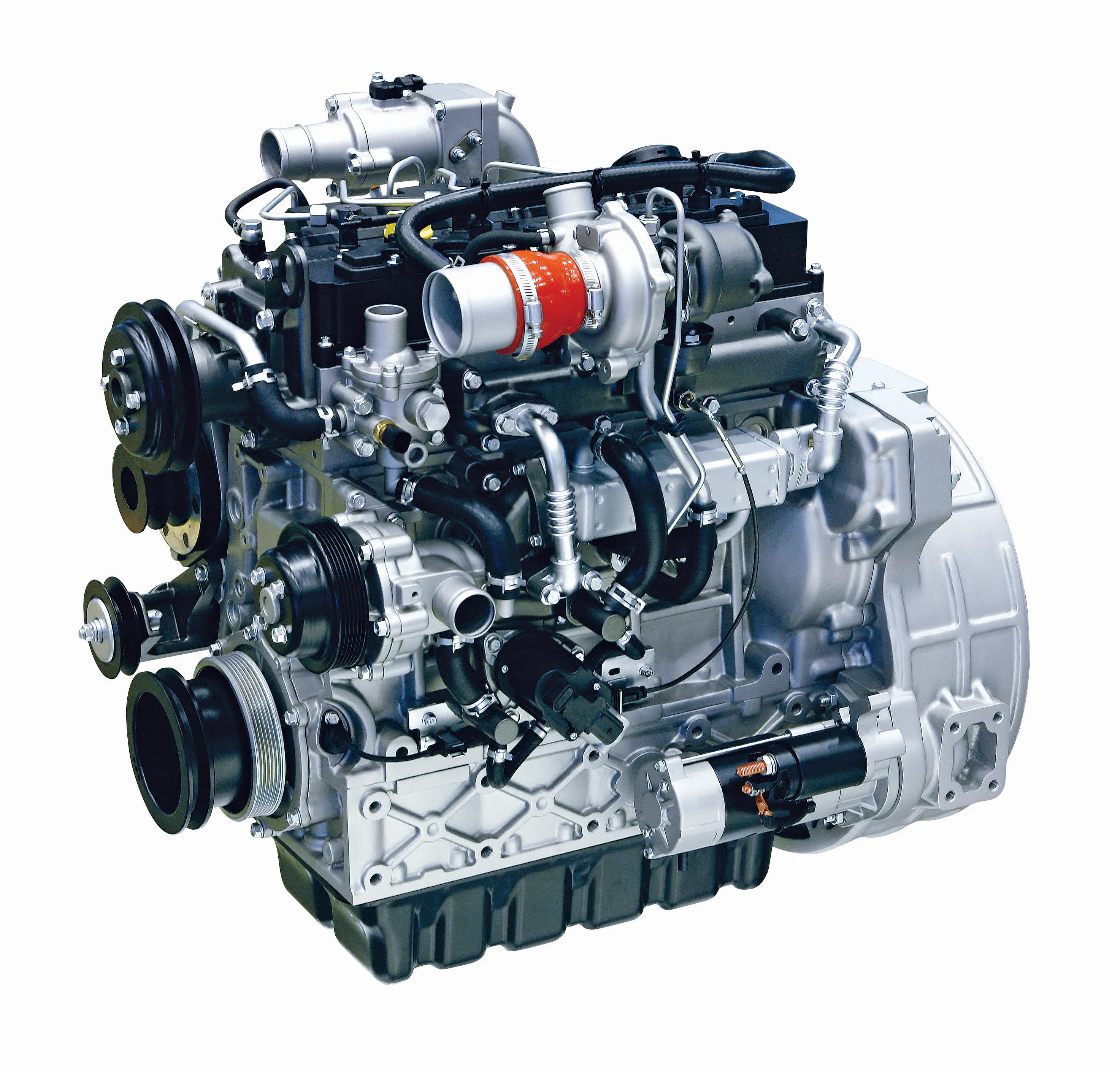

Its fourth generation Hydrostatic Transmission (HST) is said to help prolong brake life due to dynamic braking, while S-Mode gives better control in slippery conditions. Benefits include high production, improved operator comfort and reduced fuel consumption. The2300 Komatsu SAA6D107E-3 engine delivers 111kW and is equipped with a Komatsu diesel particulate filter (KDPF) and a new selective catalyst reduction (SCR) system to further reduce NOx emissions by 80%. The engine’s advanced electronic control system manages air-flow rate and fuel injection; combustion parameters and aftertreatment functions, while advanced diagnostic capabilities are also provided. It has an auto-idle shutdown system to lower fuel consumption and is said to offer reduced operating costs. The new engine controller and advanced injection timing help to increase productivity and further reduce fuel consumption.

The redesigned digging bucket improves penetration and is easier to fill, with a longer bucket bottom, a modified shape for back and side walls, and a new spill guard. Meanwhile other improvements include the KOMTRAX telematics and Komatsu Care systems that help optimise maintenance, fleet management and protect the machine against misuse, while boosting efficiency and uptime.

A key feature for this versatility is its quick coupler, which allows a wide range of attachments to be fitted. Power comes from a Tier 4 Final/Stage IV emissions compliant engine, which offers a fuel saving of up to 3% over the model being replaced. The firm claims that the machine offers high stability, breakout power and tractive effort. It has a parallel-lift linkage, with auto tilt-in to simulate a Z-bar, which can be used in a wide array of applications, from pallet handling to hard digging.

Its fourth generation Hydrostatic Transmission (HST) is said to help prolong brake life due to dynamic braking, while S-Mode gives better control in slippery conditions. Benefits include high production, improved operator comfort and reduced fuel consumption. The

The redesigned digging bucket improves penetration and is easier to fill, with a longer bucket bottom, a modified shape for back and side walls, and a new spill guard. Meanwhile other improvements include the KOMTRAX telematics and Komatsu Care systems that help optimise maintenance, fleet management and protect the machine against misuse, while boosting efficiency and uptime.