JCB has launched the brand new JS360 Auto tracked excavator to compete in the global market for excavators in the 33-40tonne market sector, marking the company's first entry in the higher end of this weight class. It will join the company's JS range of tracked and wheeled excavators, one of more than 300 products manufactured by the company, which offers a comprehensive range of 25 tracked and wheeled excavator models from 7-46tonnes.

July 10, 2012

Read time: 3 mins

It will join the company's JS range of tracked and wheeled excavators, one of more than 300 products manufactured by the company, which offers a comprehensive range of 25 tracked and wheeled excavator models from 7-46tonnes.

The new JS360 Auto tracked excavator will be manufactured at JCB's new £40 million (E44 million) Heavy Products plant following the transfer from its historic base in the centre of Uttoxeter, County Staffordshire, England, to a new site on the outskirts of the town. The 42,000m² factory, which opened in January, can produce up to 8,000 excavators a year as compared to 4,500 units at the old factory.

Matthew Taylor, JCB's CEO, said the new factory was one of the single biggest investments ever made by JCB.

JCB Heavy Products managing director John Gill said: "Without doubt, this factory is one of the most modern excavator manufacturing plants in the world and I'm extremely proud of the facility we have here.

"Since JCB began manufacturing the new JS range in 2003 we have built a reputation for the quality, durability, power, controllability, efficiency and comfort of our excavators. The massive investment we've undertaken in building this new factory means we can enhance that reputation still further by building machines of higher quality.

"JCB's range of JS tracked and wheeled excavators already have a formidable reputation for high quality. Taking those quality levels to new heights was at the heart of the decision to invest £40 million in excavator manufacturing."

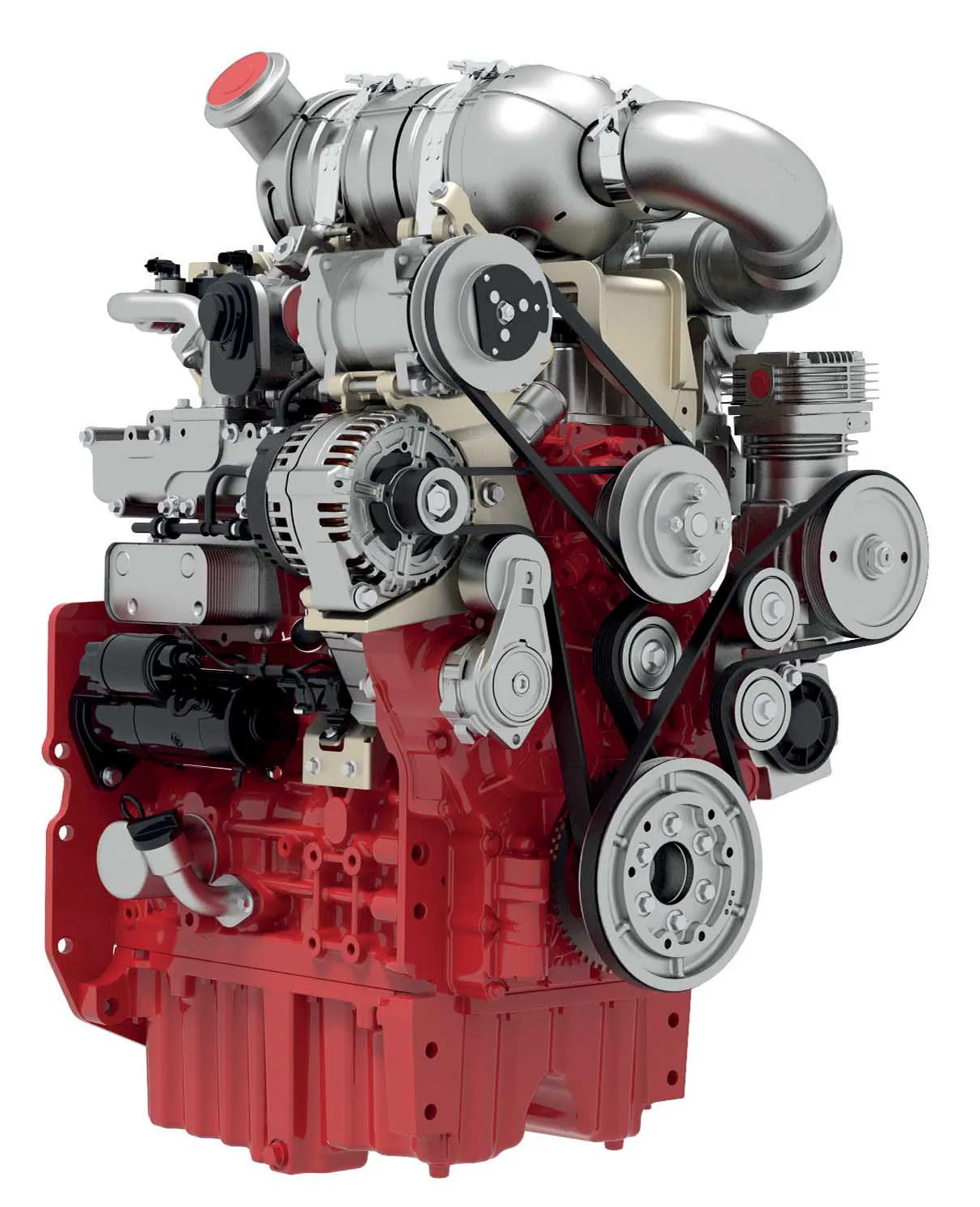

The new JS360, which has an operating weight of between 36.5-38tonnes, is said to combine high torque, pump flow and bucket breakout forces with excellent controllability to deliver a powerful, productive and accurate new machine for heavy duty applications, such as demolition, quarrying, earthmoving and roadbuilding."

It is powered by a 7.8litre, six-cylinder, Tier III-compliant