JCB’s top-of-the-range 457 wheeled loader now benefits from the firm’s new CommandPlus cab.

The machine also features a sloping engine cover and rear counterweight design, which helps improve visibility, as well as having lower noise levels and more cab space for the operator. Power for the 457 loader now comes from a Tier 4 Final/Stage IV compliant MTU diesel, which is said to offer a 16% fuel saving over the engine being replaced. As with other JCB machines, the engine in the 457 meets Tier 4 Final wit

October 2, 2014

Read time: 2 mins

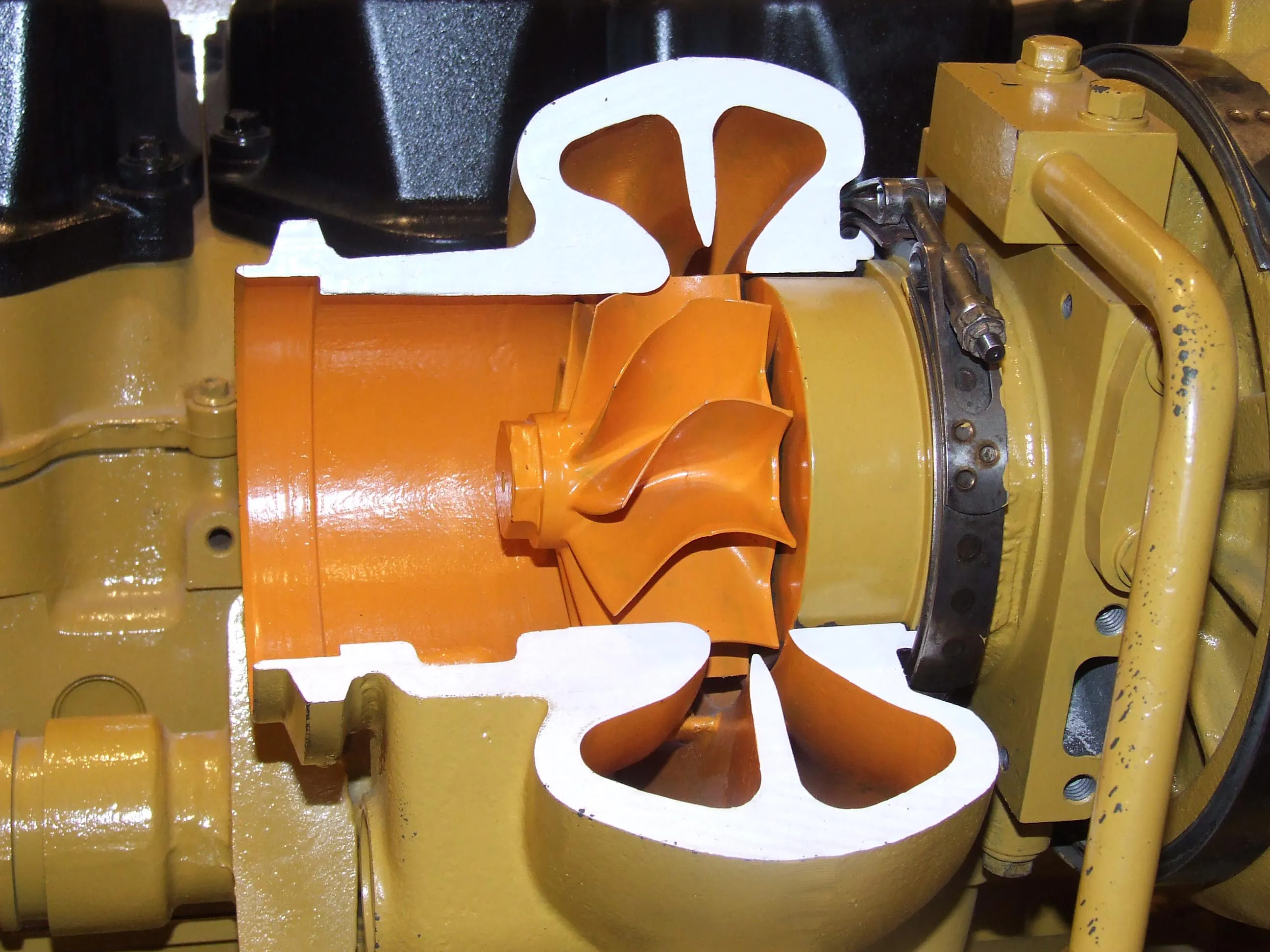

The machine also features a sloping engine cover and rear counterweight design, which helps improve visibility, as well as having lower noise levels and more cab space for the operator. Power for the 457 loader now comes from a Tier 4 Final/Stage IV compliant MTU diesel, which is said to offer a 16% fuel saving over the engine being replaced. As with other JCB machines, the engine in the 457 meets Tier 4 Final without the need for a diesel particulate filter (DPF), featuring instead selective catalytic reduction (SCR) and exhaust fluid additive to meet the emissions regulations. The 7.7litre diesel delivers 193kW, an increase over the 186kW of the previous engine and in spite of a reduction in capacity. The company claims the new engine delivers more power at lower revs, which helps cut noise levels as well as fuel consumption. The diesel is said to be well-matched to the standard four-speed or optional five-speed transmissions, further boosting efficiency.

The new CommandPlus cab has an improved ROPS structure with its A pillars providing a larger interior with a wide front windscreen. The machine also has revised pedals, a new adjustable steering column and seat-mounted hydraulic controls. Other improvements for the operator include all-round LED lighting, a cab door hinged at the front for better access and mirrors that have been repositioned for better visibility, and are also available with an optional heating package.

The Tier 4 JCB 457 comes as standard with JCB’s LiveLink telematics technology, offering fleet managers with remote access to real-time fuel consumption and machine working data, including operating hours and fault codes. This system also allows the machine to be geofenced, helping tackle theft.