Hitachi design engineers have incorporated new TRIAS II technology into the Zaxis-6 range of excavators to meet EU Stage IV emission regulations. Hydraulic loss is decreased by reducing the amount of hydraulic oil returned to the tank due to cooperative control of the pump and valve. Two solenoid valves have been added to control the pump flow effectively, lowering fuel consumption. An auto shutdown feature also prevents fuel wastage, as well as reducing noise levels, exhaust emissions and CO2.

Inside the cab, the technology within the multi-function LCD monitor enables operators to check the machine’s status and settings at a glance, and the new machine also has Hitachi’s remote monitoring Global e-Service.

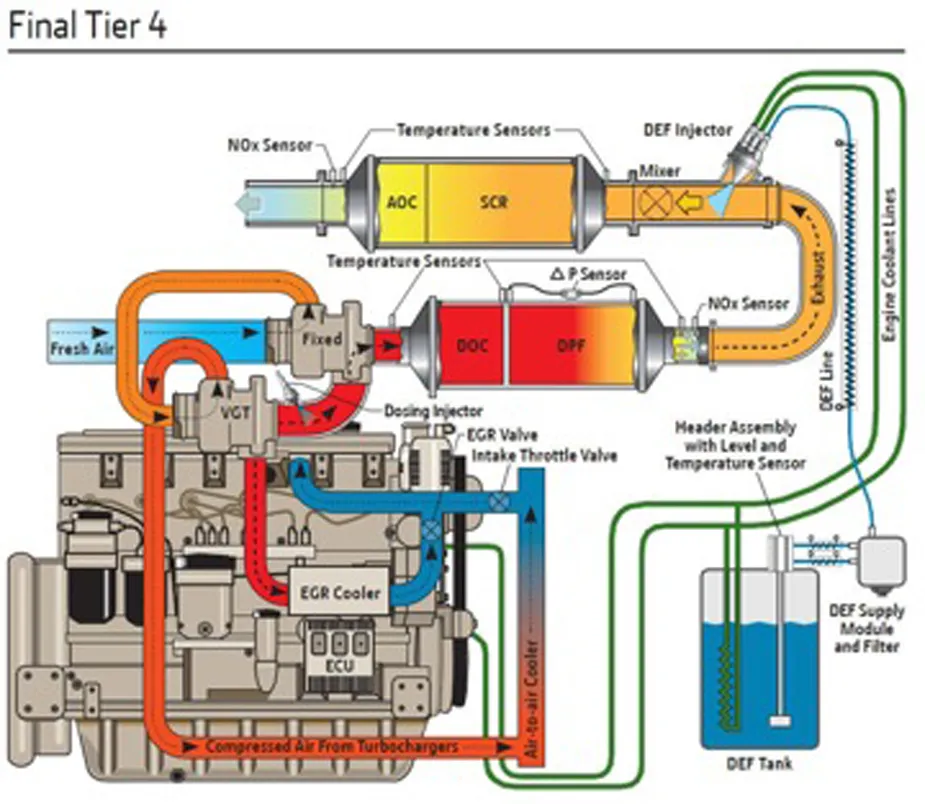

Another significant change to the Zaxis-6 range is the implementation of a selective catalytic reduction (SCR) system. A urea solution is injected into the exhaust gas of the excavators to reduce nitrous oxide from the emissions. An after-treatment device, integrated with diesel oxidation catalyst, urea water mixing pipe, SCR catalyst and silencer, has also been incorporated.

The engine output of the 30tonne class ZX300LC-6 has been increased to 186kW, compared to 140kW for the ZX290LC-5.

Hiroyuki Kamata, HCME general manager of engineering, was involved in the design and testing of the new Hitachi Zaxis-6 excavators.

“Our first priority was to ensure that the machine worked properly, and the next priorities were the controllability and operating experience,” he says. “Overall the results were positive in terms of performance. We are confident that Hitachi customers will be happy operating the new Zaxis-6 models.”

Hitachi launches the first Zaxis-6 excavator in Europe

Hitachi Construction Machinery (Europe) has presented the first model of its Zaxis-6 medium excavator range, the X300LC-6, which is said to benefit from several enhancements made to the Zaxis-5 range. Hitachi design engineers have incorporated new TRIAS II technology into the Zaxis-6 range of excavators to meet EU Stage IV emission regulations. Hydraulic loss is decreased by reducing the amount of hydraulic oil returned to the tank due to cooperative control of the pump and valve.

April 23, 2015

Read time: 2 mins