When Flannery Plant Hire was awarded work on the Norwich bypass project, they purchased a wide range of new

Caterpillar dealer

The Cat 730C ejector unit creates a safer working environment by displaying payload weight and status including external lights which automatically signal when target payload has been achieved.

The payload on the machine is shown on the in-cab monitor which enables operators to ensure the truck is not under or overloaded, which in turn optimises fuel burn per tonne on each cycle meaning the productivity of the machines are more efficient.

This information can be used by Balfour Beatty to provide the best possible carbon footprint on site as well as being able to see the impact of the fleet.

CPM tracks and measures data such as tonnes per load, tonnes per cycle and distance travelled per day. It also measures litres of fuel a machine burns per hour which gives the project a daily overview of progression.

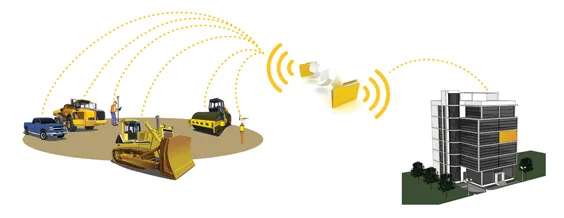

No matter where the units are working on the new 20km dual carriageway, data can be sent and received in real time. For the team on site, this data is sent via VisionLink into the online portal where management and the Balfour Beatty team access it from any connected location. By combining CPM with additional data relating to the health of machines through VisionLink, potential issues with machines are more visible which results in a significant reduction in downtime.