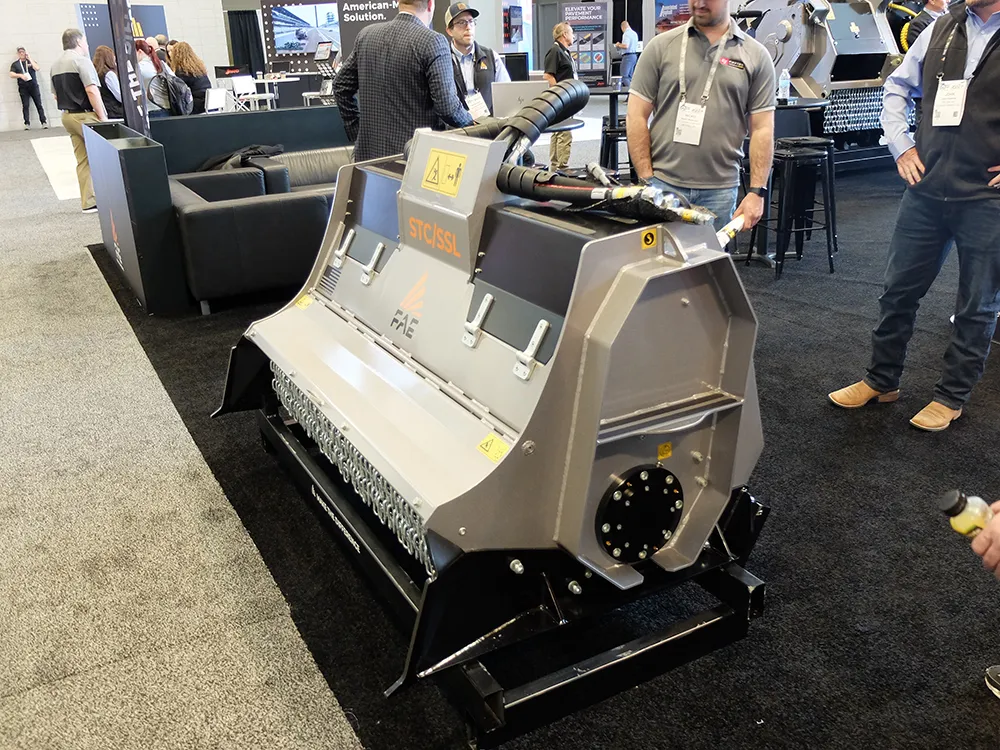

Italian manufacturer FAE recently announced four new soil stablisers and also upgrades to another series.

The four new models - STABI/FRS, STABI/FRS/HP, STABI/H and the STABI/H/HP – are exceptional at handling stony ground, according to the manufacturer, based in the town of Fondo, near Trento, northern Italy.

The STABI/FRS and the STABI/FRS/HP feature a fixed-rotor system that offers an operating depth up to 60cm and are compatible with tractors from 223kW (300hp) to 373kW (500hp). Suitable for small worksites and large infrastructures, the STABI/FRS features a brand new rotor design for improved stabilisation with reduced power usage.

Also, a new mixing chamber allows processing of all types of soil. The structural frame along with the use of special materials such as tungsten-carbide and Hardox ensure improved wear resistance.

The STABI/H and STABI/H/HP offer professional stabilisation without compromise. Designed for tractors between 223kW (300hp) to 373kW (500hp), these machines feature a variable geometry chamber and operating depth up to 50cm. The next-generation stabiliser - the STABI/H - is designed for the most challenging applications including road building, motorways, railways, parking areas and commercial zones, industrial plants and other infrastructural works.

FAE says that the newly designed rotor and innovative tooth holder guarantee long working sessions under any conditions and produces unmatched efficiency. The variable geometry chamber and transmission built into the rotor allows the soil to be processed with extreme precision and high quality.

For all four models, FAE offers the new teeth A/3 as standard and A/3/HD as optional, in addition to F/3 and F/3/R range (optional). Both ranges can be used with the automatic FCS (full control system) for optimal mixing of soil and management of humidity (optional) for customers with the most demanding applications.

FAE, founded in 1989, designs and produces heads for tractors, excavators, skid steers, special vehicles and tracked vehicles for forestry, agricultural, road and de-mining operations. The company has more than 90 products and 400 models. FAE also has tracked vehicles with a cab as well as radio-controlled tracked vehicles.