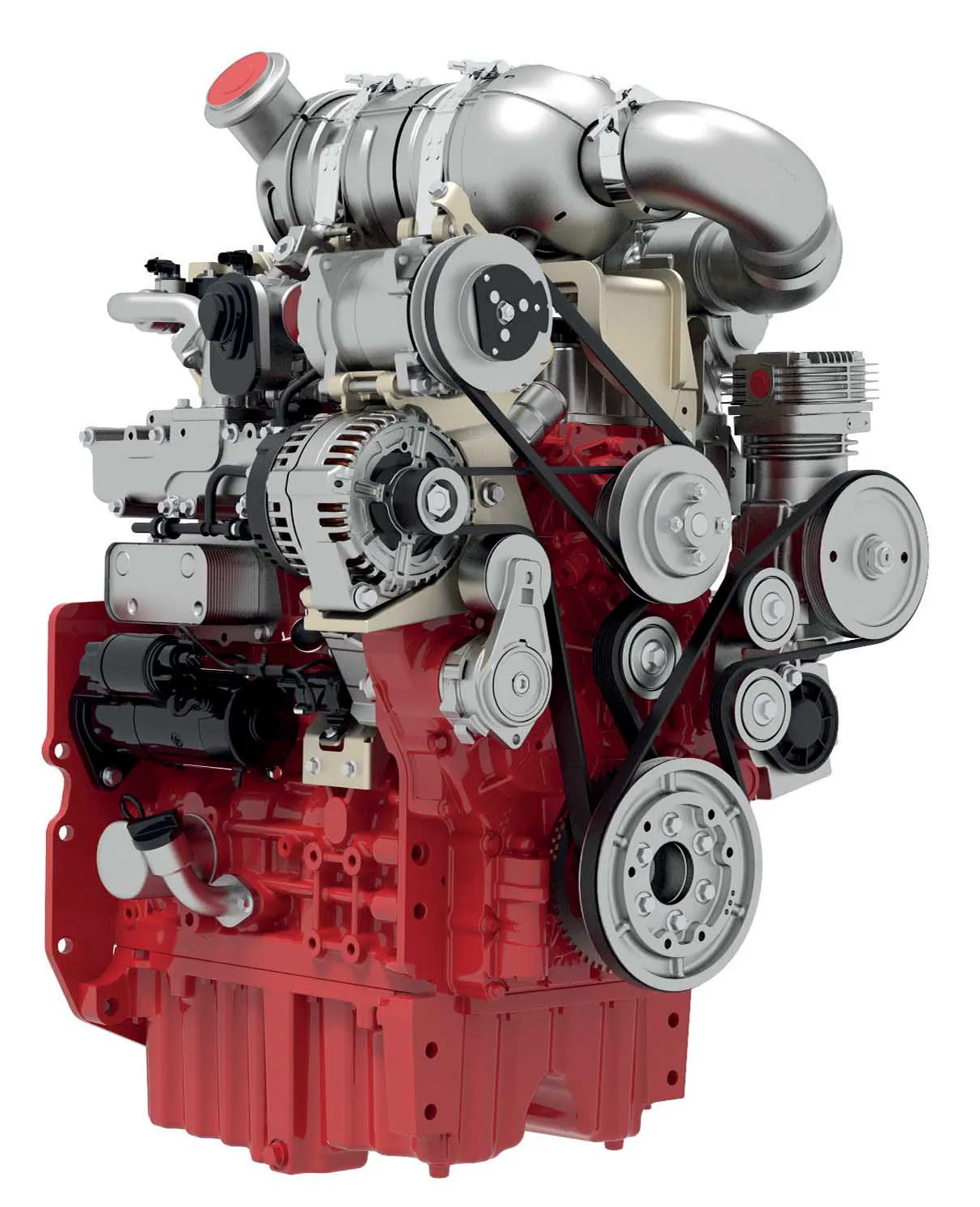

The DA30-7 is powered by the new Scania Stage V compliant DC09 9litre diesel providing 276kW. The DA45-7 is driven by the new Scania Stage V DC13 13litre diesel delivering 368kW.

The new engines have undergone two years of intensive testing. While the core of the Scania engines has not changed, the new units benefit from improved aftertreatment.

A number of changes on the new ADTs improve safety, comfort and serviceability. These include lower positions for the diesel and AdBlue tanks, allowing the operator to fill both from ground level. The greasing system has been relocated to make it easily accessible from ground level. In addition, the transmission filters have been installed close to the greasing system, where they are easy to access.

Both machines are equipped with additional external round hand rails and benefit from upgraded electronic and hydraulic systems.

Like all Doosan ADTs, the new models feature an articulation hinge positioned behind the turning ring, which is said to optimise weight distribution to the front axle. Combined with the free-swinging rear tandem bogie, this ensures equal distribution of weight to each wheel for better power delivery on difficult terrain.