Hamm is now offering new vibration crusher drums for its HC Series compactors. The machines feature new tool holders, can handle crushing and compacting in a single step and meet Stage V/Tier 4 Final emissions requirements, with Tier 3 emissions variants due shortly.

These compactors have been designed specifically to crush and compact rock and stone, allowing processes onsite to be streamlined by reducing the work and expense needed for material preparation and transport. For customers, this means time, cost and CO₂ emissions can be cut by up to 50%.

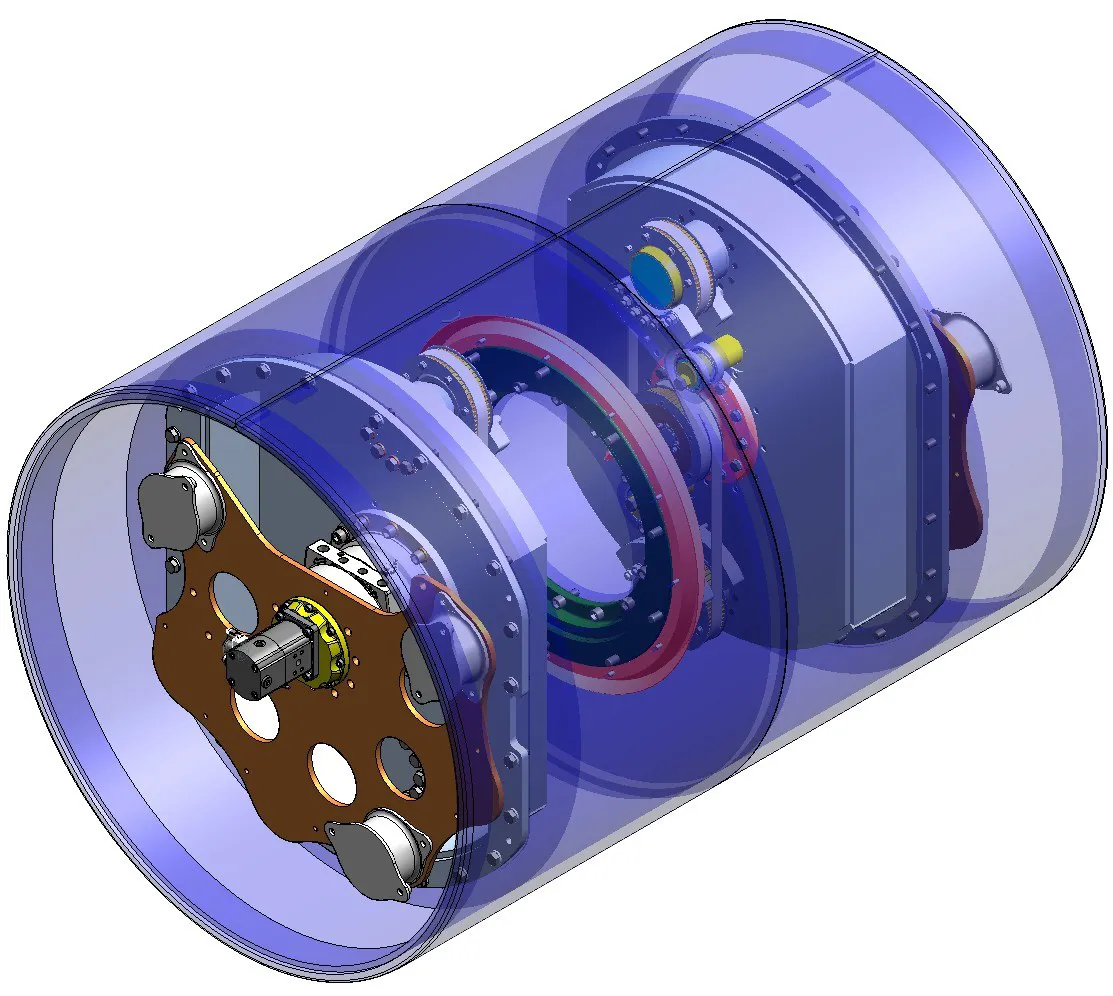

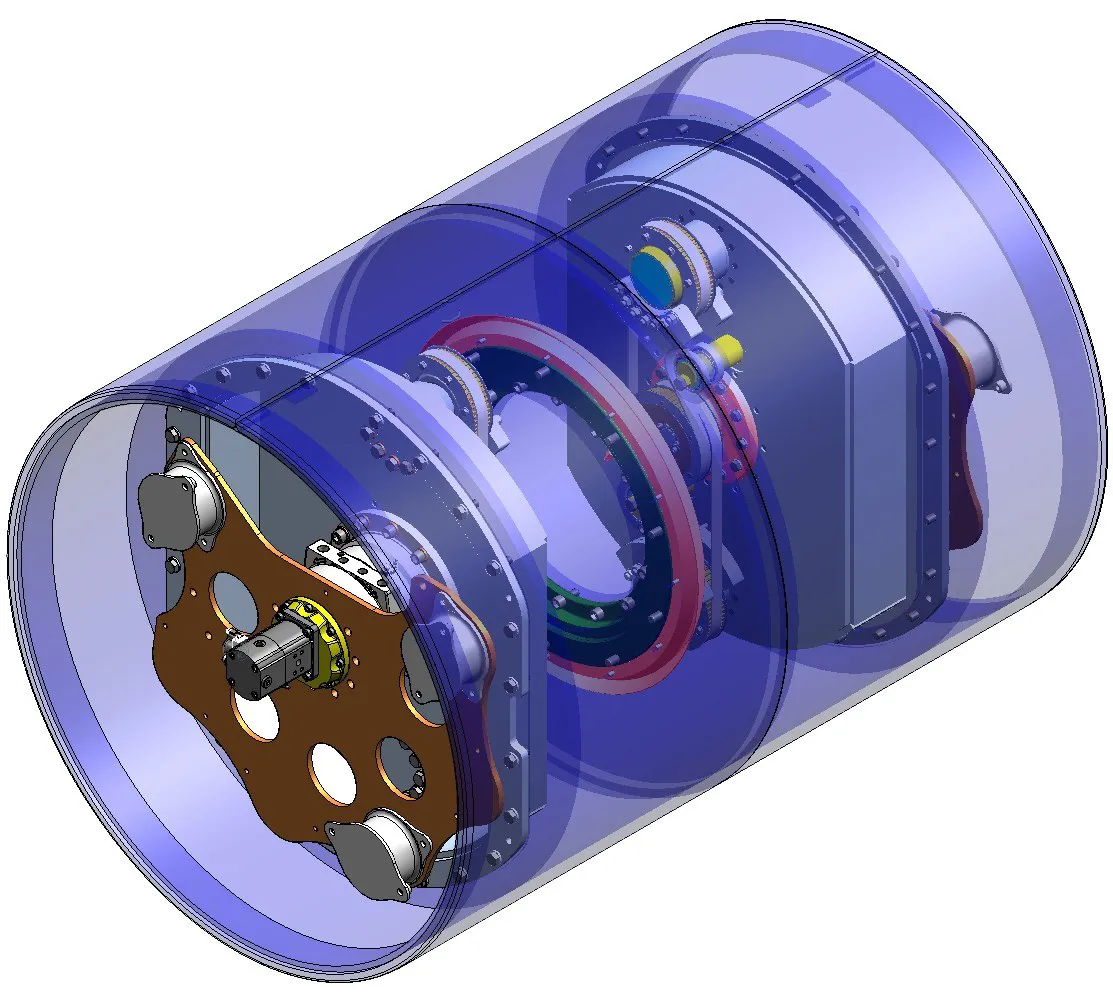

The HC 250 C VC (Tier 3) and HC 250i C VC (Stage V/ Tier 4F) compactors are able to crush and compact mixed soils, stones such as basalt and granite, and other construction materials.

Featuring Deutz engines and reinforced components around the front frame, three-point articulation and the underbody, the compactors can cope with tough applications. The reinforced drum drives allow operation on capable of inclines up to 60%, while the 25tonnes machines have heavy-duty tyres for rocky terrain. The units have the firm’s Easy Drive system as standard and the cab design is said to be roomy and offer good all-round view. The new tool holder system is compatible with round-shank cutting tools for stone, as well as wear-resistant heavy-duty cutting tools with carbide tips and hard facing for abrasive stone or hard stone. The tool insert attachments have been designed to ensure quick assembly and removal, lowering maintenance costs. Existing machines (H 25i VC/3625 VC) can also be fitted with the new-design too holder system by switching the drum.

The new VC compactors can be used in a range of applications, including road planing works in tunnel building or to pre-crush and loosen stone. This takes a lot of hard work out of subsequent processes, such as layer-by-layer milling off.