International construction equipment manufacturer Chicago Pneumatic has introduced versions of its CPS 11.0 (7bar) and CPS 11-12 (12bar) portable compressors aimed at the European market. The compressors feature Deutz EU compliant Stage 3B engines and are meant for surface drilling, abrasive blasting and ice blasting and excel in road work and shotcrete pumping. The 12bar variant is also suitable for special applications such as fibre optic cabling. The higher working pressure enables the CPS 11-12 compress

March 9, 2015

Read time: 2 mins

International construction equipment manufacturer 6097 Chicago Pneumatic has introduced versions of its CPS 11.0 (7bar) and CPS 11-12 (12bar) portable compressors aimed at the European market.

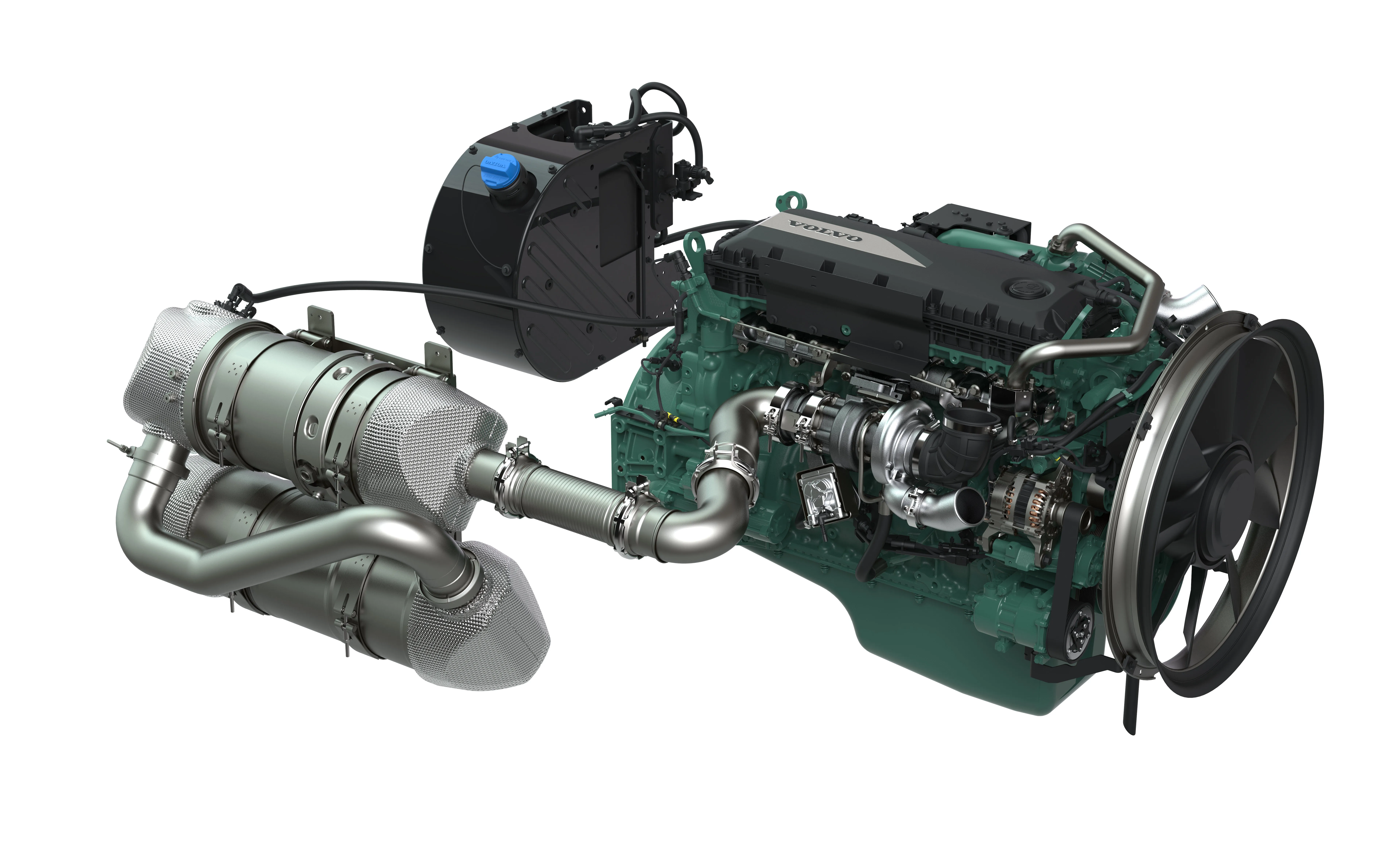

The compressors feature201 Deutz EU compliant Stage 3B engines and are meant for surface drilling, abrasive blasting and ice blasting and excel in road work and shotcrete pumping.

The 12bar variant is also suitable for special applications such as fibre optic cabling. The higher working pressure enables the CPS 11-12 compressor to push cabling through longer pipeline distances without pressure loss.

The Deutz engine uses Exhaust Gas Recirculation technology in combination with a Diesel Oxidation Catalyst and for the CPS 11-12 a Diesel Particulate Filter to sharply reduce the output of particulate matter and nitrogen oxides. As a result, the CPS 11.0 and CPS 11-12 are more environmentally friendly than previous models and provide operators with the benefit of increased fuel efficiency at partial load.

Another new feature is the easy-to-use central electronic controller that provides operators with an improved user interface and straightforward control and monitoring options. The electronic controls also make it easy for operators to quickly start and stop the compressor and regulate automatic cool-down after the unit has been running at full load.

With large 175litre fuel tanks the compressors can be run non-stop at full load for an entire shift without refueling. A fully automatic step-less speed regulator also means the engine speed can be adapted to air demand.

Additional options include a braked undercarriage with a fixed or height adjustable tow bar, a non-braked undercarriage with fixed tow bar, jockey wheel, leg support and several towing eye options.

The compressors feature

The 12bar variant is also suitable for special applications such as fibre optic cabling. The higher working pressure enables the CPS 11-12 compressor to push cabling through longer pipeline distances without pressure loss.

The Deutz engine uses Exhaust Gas Recirculation technology in combination with a Diesel Oxidation Catalyst and for the CPS 11-12 a Diesel Particulate Filter to sharply reduce the output of particulate matter and nitrogen oxides. As a result, the CPS 11.0 and CPS 11-12 are more environmentally friendly than previous models and provide operators with the benefit of increased fuel efficiency at partial load.

Another new feature is the easy-to-use central electronic controller that provides operators with an improved user interface and straightforward control and monitoring options. The electronic controls also make it easy for operators to quickly start and stop the compressor and regulate automatic cool-down after the unit has been running at full load.

With large 175litre fuel tanks the compressors can be run non-stop at full load for an entire shift without refueling. A fully automatic step-less speed regulator also means the engine speed can be adapted to air demand.

Additional options include a braked undercarriage with a fixed or height adjustable tow bar, a non-braked undercarriage with fixed tow bar, jockey wheel, leg support and several towing eye options.