Caterpillar is introducing its M Series 3 grader, the 12M3, 140M3, 160M3 as well as the all-wheel-drive (AWD) variants. These machines feature Tier 4 Final/Stage IV emissions control technology as well as durability, productivity and operator comfort. High fuel efficiency is claimed along with better serviceability and the emissions reduction technology requires no need to stop for regeneration.

The emissions control system uses Caterpillar’s aftertreatment solution with the addition of selective cataly

October 2, 2014

Read time: 2 mins

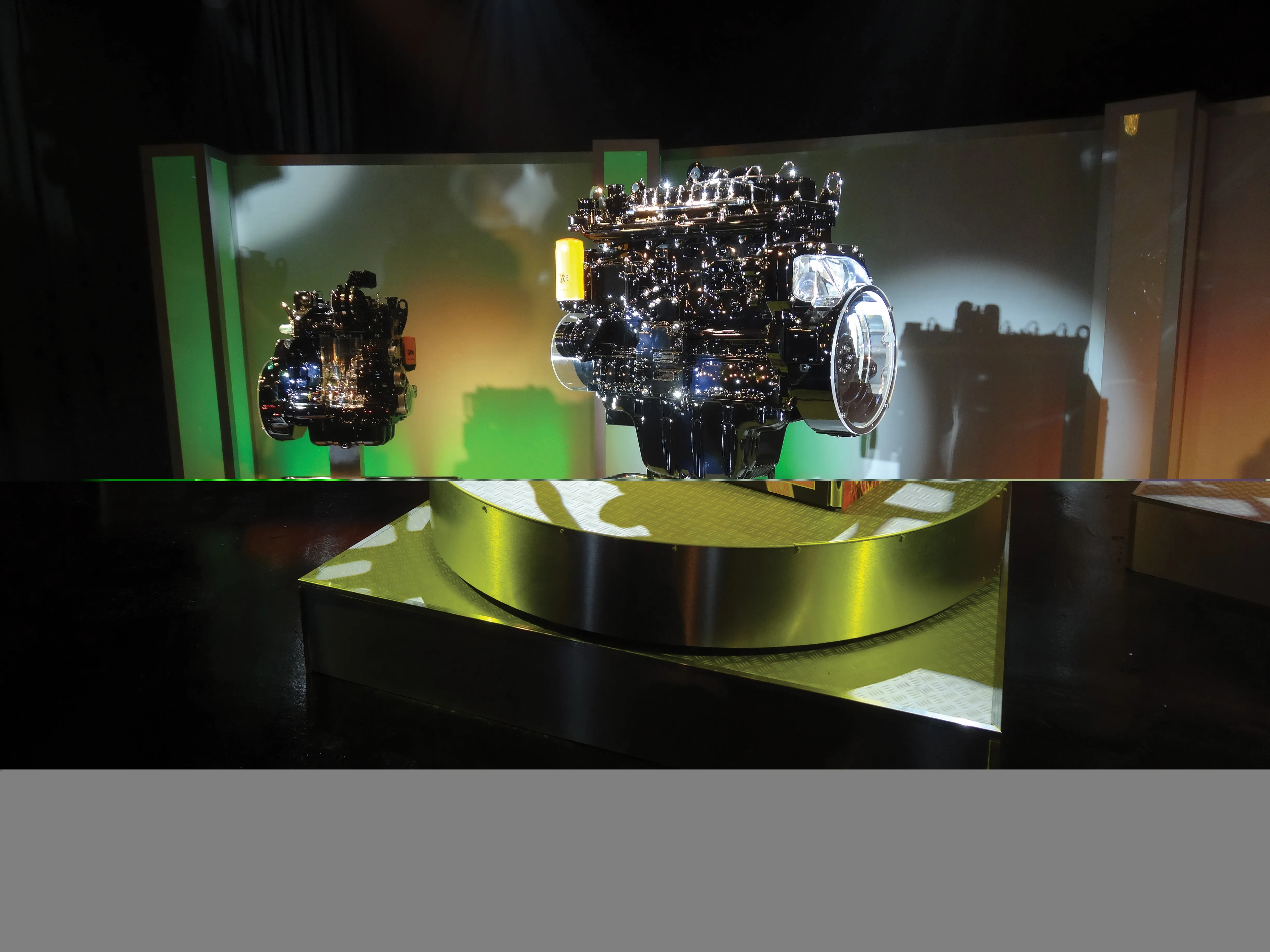

The emissions control system uses Caterpillar’s aftertreatment solution with the addition of selective catalytic reduction (SCR). A new standard economy (ECO) mode can be turned on to help save fuel by reducing engine speed so the machine works in a more efficient range. The average fuel saving is up to 10%, depending on the application.

The machine also has the Cat Connect system, which uses a combination of technology and services to help boost job site efficiency.

The graders are equipped with Product Link, which helps fleet owners track location, hours, fuel usage, productivity, idle time, and diagnostic codes through the online VisionLink interface. M Series 3 machines also offer optional grade technologies such as the Cat Grade Control Cross Slope and Cat AccuGrade system.

The standard 12M3 model weighs in at 19.34tonnes while the all-wheel-drive version weighs 20.23tonnes, with both variants powered by a 133kW Cat diesel and equipped with 3.7m moldboards.

The standard 140M3 weighs 19.93tonnes while the all-wheel-drive variant is 20.83tonnes, with both powered by a 149kW diesel and featuring the same 3.7m wide moldboard as the smaller machines. The 160M3 weighs 20.7tonnes in standard form and 21.55tonnes in all-wheel-drive configuration, with both powered by 165kW diesels and featuring 4.2m wide moldboards.