The new Cat D6K2 Track-Type Tractor is said by Cat to deliver unmatched finish grading performance and improved fuel economy. Its new Stable Blade Control feature is said to utilise technology which complements operator blade control input, making it the best finish grading tractor in the industry. Eco Modes, both forward and/or reverse, is claimed by Cat to improve fuel economy by up to 22% depending on the applications for lower operating costs.

The new D6K2 uses the Cat C6.6 ACERT engine that meets Stag

January 18, 2013

Read time: 2 mins

The new 178 Caterpillar D6K2 Track-Type Tractor is said by Cat to deliver unmatched finish grading performance and improved fuel economy.

Its new Stable Blade Control feature is said to utilise technology which complements operator blade control input, making it the best finish grading tractor in the industry. Eco Modes, both forward and/or reverse, is claimed by Cat to improve fuel economy by up to 22% depending on the applications for lower operating costs.

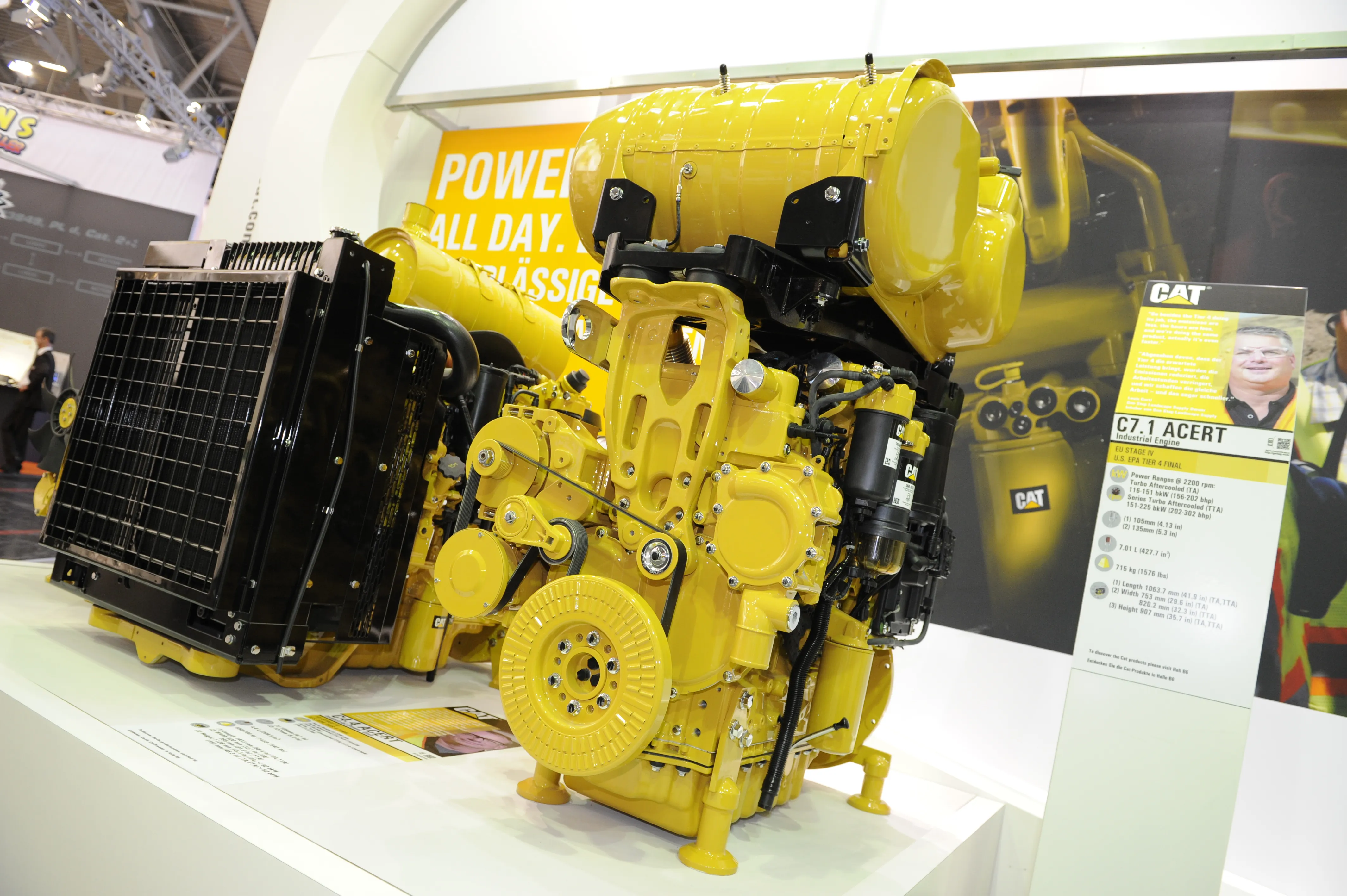

The new D6K2 uses the Cat C6.6 ACERT engine that meets Stage IIIB and Tier 4 Interim emissions requirements. K2 models feature hydrostatic drive with Traction Control, said to reduce track slip at maximum load. New wider blades are said by Cat to allow more ground to be covered in one pass, providing up to 8% better productivity in slot dozing applications. New manual adjustable pitch is said to allow the operator to control blade pitch fore/aft for maximum productivity in various material conditions.

The K2 models are said by Cat to blend their new features with the basic field-proven design of their K Family predecessors, a design that includes single-lever travel/steering control, spacious operator’s station with standard air conditioning with cab-equipped, single-lever blade control, Cat Sealed-and-Lubricated Track (S<) or Cat SystemOne undercarriage for lowest undercarriage cost per hour.

The D6K2 is also said to benefit from the recently introduced undercarriage improvements of the D6K. The combination of eight bottom rollers and two carrier rollers are said by Cat to ensure a smoother ride and better finish grading capabilities at a higher speed.

Net power ratings are 97kW at 2,200rpm. The new C6.6 ACERT engine also features Air To Air After Cooling, a new electric fuel priming pump, and a passive regeneration system for emissions reduction.

Its new Stable Blade Control feature is said to utilise technology which complements operator blade control input, making it the best finish grading tractor in the industry. Eco Modes, both forward and/or reverse, is claimed by Cat to improve fuel economy by up to 22% depending on the applications for lower operating costs.

The new D6K2 uses the Cat C6.6 ACERT engine that meets Stage IIIB and Tier 4 Interim emissions requirements. K2 models feature hydrostatic drive with Traction Control, said to reduce track slip at maximum load. New wider blades are said by Cat to allow more ground to be covered in one pass, providing up to 8% better productivity in slot dozing applications. New manual adjustable pitch is said to allow the operator to control blade pitch fore/aft for maximum productivity in various material conditions.

The K2 models are said by Cat to blend their new features with the basic field-proven design of their K Family predecessors, a design that includes single-lever travel/steering control, spacious operator’s station with standard air conditioning with cab-equipped, single-lever blade control, Cat Sealed-and-Lubricated Track (S<) or Cat SystemOne undercarriage for lowest undercarriage cost per hour.

The D6K2 is also said to benefit from the recently introduced undercarriage improvements of the D6K. The combination of eight bottom rollers and two carrier rollers are said by Cat to ensure a smoother ride and better finish grading capabilities at a higher speed.

Net power ratings are 97kW at 2,200rpm. The new C6.6 ACERT engine also features Air To Air After Cooling, a new electric fuel priming pump, and a passive regeneration system for emissions reduction.