Building on an 80-year history of serving customers in Russia, Caterpillar used the first CONEXPO Russia trade show in Moscow to unveil the first hydraulic excavator assembled at its facility in Tosno, Russia.

March 7, 2012

Read time: 2 mins

Building on an 80-year history of serving customers in Russia, 178 Caterpillar used the first 3485 Conexpo Russia trade show in Moscow to unveil the first hydraulic excavator assembled at its facility in Tosno, Russia.

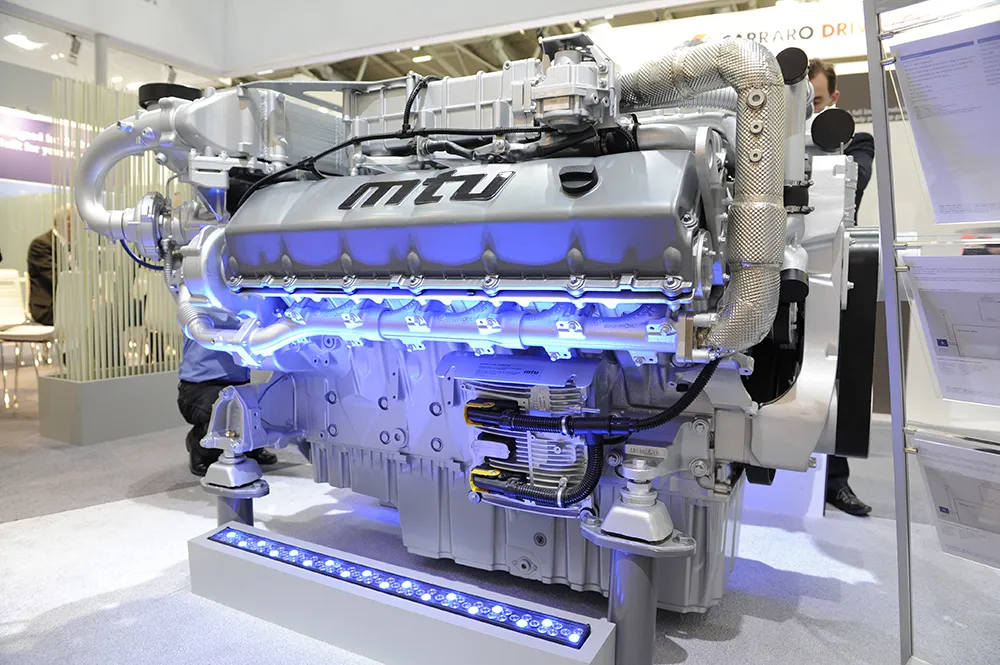

The 320D hydraulic excavator was one of more than two dozen Caterpillar machines and engines displayed along with a full range of4018 Caterpillar Paving and road building products and services.

Earlier this year Caterpillar, which is celebrating the 35th anniversary of its first business office in Russia, opened in 1973 in Moscow, announced it was implementing its long-planned strategy to include core machine assembly operations in its existing component production facility at Tosno, where it has manufactured components since 2000. The components from Russia are sent to other Caterpillar machine factories in Europe.

The hydraulic excavators assembled in Tosno are the first core machines Caterpillar has produced in Russia, and they will be sold to customers in the rapidly expanding Russian market.

"In the last five years, our sales in Russia have increased more than 550% as we have supported customers who are playing a critical role in the strong growth and positive economic development taking place across Russia," said Jim Owens, Caterpillar's chairman and CEO. "The expansion of our operations in Russia in recent years, including the addition of excavator assembly at our Tosno facility, demonstrates our commitment to customers in Russia." In recognition of the importance of the Russian market to the pipeline industry, CONEXPO Russia (held in September) was also the first trade show where Caterpillar displayed its newest pipelayer, the PL61. With an 18ton (16.3tonne) lift capacity, the PL61 was designed and built primarily for pipeline contractors working in the most challenging environments. It features a Caterpillar C6.6 engine featuring ACERT Technology, and meets all current global emissions standards.

Today, Caterpillar and its dealers have more than 100 locations and 4,000 employees in Russia and the Commonwealth of Independent States (CIS).

The 320D hydraulic excavator was one of more than two dozen Caterpillar machines and engines displayed along with a full range of

Earlier this year Caterpillar, which is celebrating the 35th anniversary of its first business office in Russia, opened in 1973 in Moscow, announced it was implementing its long-planned strategy to include core machine assembly operations in its existing component production facility at Tosno, where it has manufactured components since 2000. The components from Russia are sent to other Caterpillar machine factories in Europe.

The hydraulic excavators assembled in Tosno are the first core machines Caterpillar has produced in Russia, and they will be sold to customers in the rapidly expanding Russian market.

"In the last five years, our sales in Russia have increased more than 550% as we have supported customers who are playing a critical role in the strong growth and positive economic development taking place across Russia," said Jim Owens, Caterpillar's chairman and CEO. "The expansion of our operations in Russia in recent years, including the addition of excavator assembly at our Tosno facility, demonstrates our commitment to customers in Russia." In recognition of the importance of the Russian market to the pipeline industry, CONEXPO Russia (held in September) was also the first trade show where Caterpillar displayed its newest pipelayer, the PL61. With an 18ton (16.3tonne) lift capacity, the PL61 was designed and built primarily for pipeline contractors working in the most challenging environments. It features a Caterpillar C6.6 engine featuring ACERT Technology, and meets all current global emissions standards.

Today, Caterpillar and its dealers have more than 100 locations and 4,000 employees in Russia and the Commonwealth of Independent States (CIS).