One was the production of its 10,000th vibratory compactor, while the other was the highest monthly sales volume reached in its 25 years of operations at the facility. Case Construction Equipment has rolled out the 10,000th vibratory compactor from its manufacturing plant in Pithampur, India. It claims to be the only manufacturer in India to have reached this milestone. The firm marked this important achievement with an official ceremony to hand over the unit to its new owner, P D Agrawal, chairman, P D Agrawal Infrastructure, Indore. The keys to the new Case 1107EX Soil Compactor were handed over by Stefano Pampalone, chief operating officer for Case CE in the Asia Pacific region.

And in addition the Pithampur plant also saw another record result, with the highest number of vibratory compactors sold in a single month in the facility’s 25-year history. These two milestones helped CASE to consolidate its strong position in India’s important compaction equipment segment.

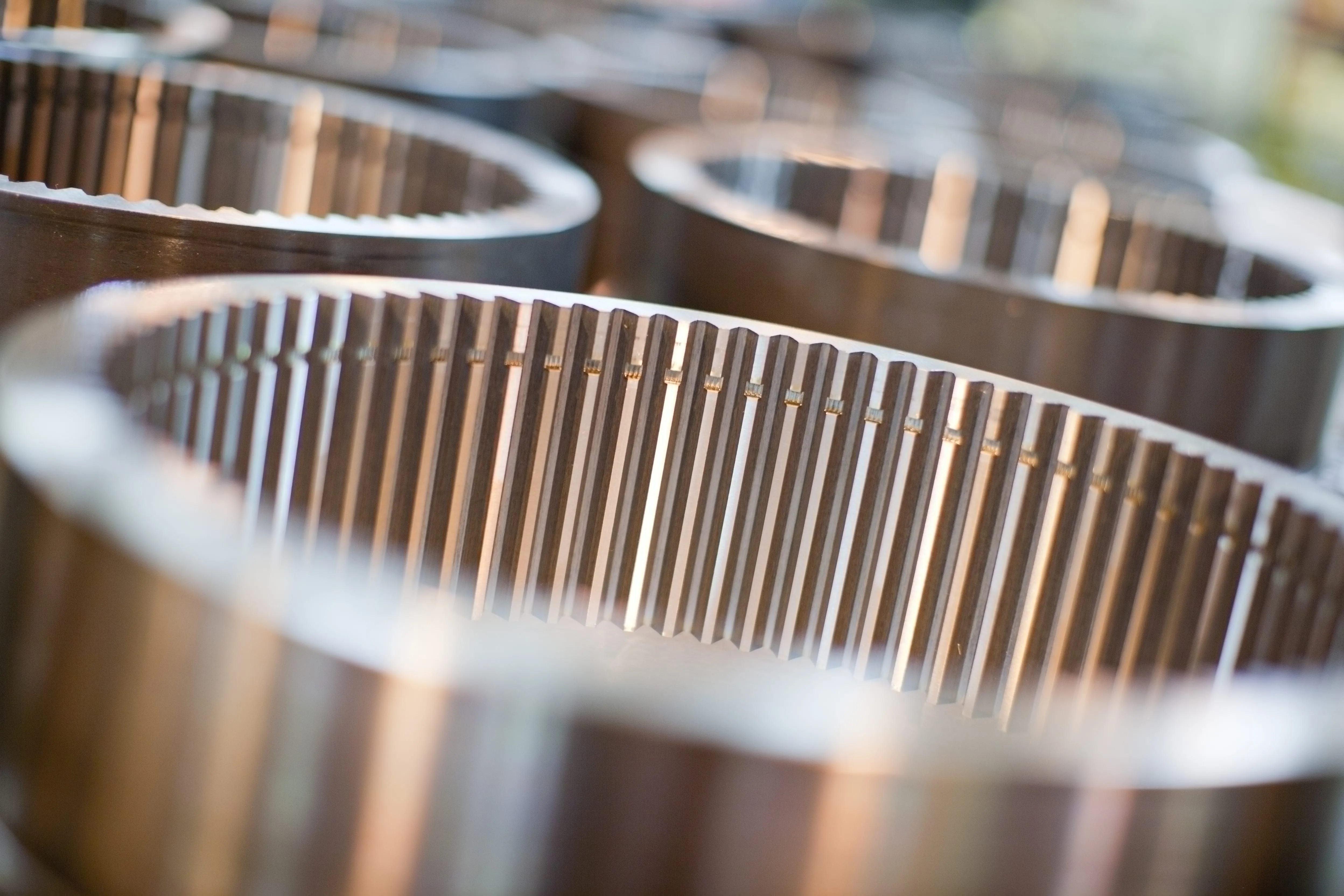

Abhijit Gupta, brand leader, Case Construction Equipment India, commented, “These achievements are testament to the popularity of CASE vibratory compactors in India. Case is the leader in this market segment in the country. Road construction companies across the country remain loyal to Case vibratory compactors, appreciating their simple design, which makes it easy to use and to maintain, and their exceptional reliability.”

The demand for vibratory compactors is steeply increasing as a result of the Indian Government’s push to develop the country’s road transport network in order to support economic growth. Road construction has gone from a rate of 13km/day of roads built in 2013 and 2014 to nearly 20km/day in the period between 2016 and 2017. The Case Pithampur plant has been able to meet the resulting hike in demand, keeping pace with this fast-growing market, and has started to export its successful vibratory compactors to neighbouring countries.

The Case Pithampur manufacturing plant also participates in CNH Industrial’s World Class Manufacturing programme, which have earned the facility several industry awards.