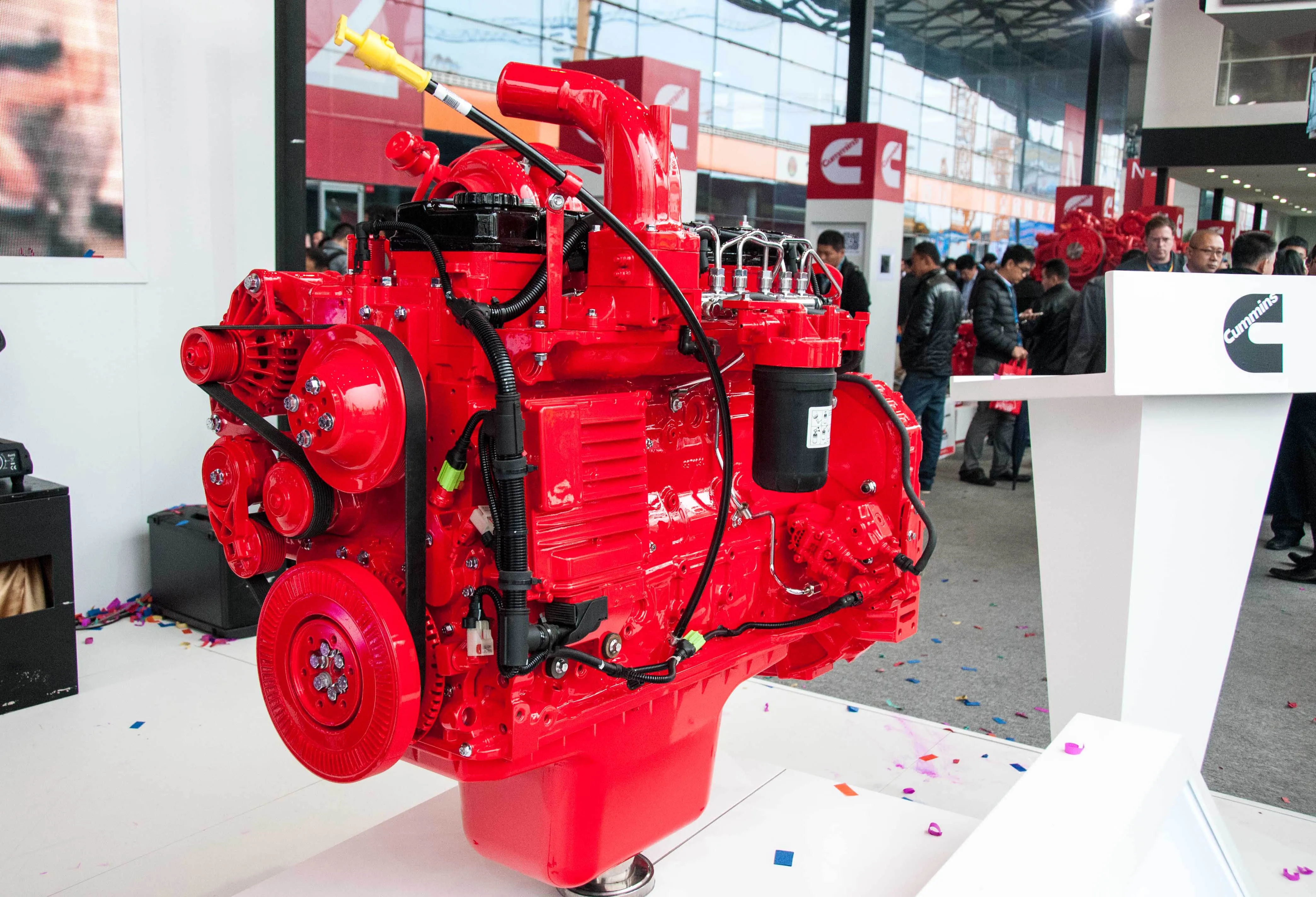

There are three key components: a rock drill delivering 30kW for fast penetration, robust boom, and engine choices for different emissions requirements. The rig comes equipped with the COP 3060 hydraulic rock drill. A high feed force can be applied while ensuring holes are straight due to the newly designed extension boom. It provides easy positioning and has a robust aluminium chain-feed. There is choice of engine between a 9litre Tier 3 unit or a 9.3litre Tier 4 unit, both of which deliver 261kW.

The T50 drills holes in the 102-152mm range. Feed extension is 1.9m with a total length of 9.37m and travel length of 5.4m. Both feed rate and feed force are 50kN. It is equipped with a 20m2 filter area with a maximum cleaning air pressure of 8 bar.

“The market is looking for machines with real power, robust, easy to operate, environmentally friendly and that can deliver fuel savings,” said Goran Popski, marketing manager. It seems Atlas Copco has managed this. The rig was tested in mines in China, the USA and South Africa. Eire Contractors, the test client in South Africa, has already placed an order for five machines.