However, the HX04 dump truck is not intended as a prototype for an imminent production model. David Forget is a key member of the engineering team who has worked on the project and explained, “It’s a functional prototype.” He continued that it forms part of the firm’s investigation into different possible drive systems for future machines. “It is a vision of Volvo and we are exploring new technologies.”

As this is a working research project rather than the finalisation for an upcoming production model, the machine only has a 20tonne payload while its four high-pressure hydrogen tanks (at 700bars) allow a working time of around four hours. He commented, “The tank is a very sensitive part. There’s carbon around the tank for strength and it has a liner to prevent hydrogen leakage.” Meanwhile, the fuel cell itself is the product of a joint venture between Volvo and Mercedes and has had to be well-protected against the tough ADT application. He added, “A fuel-cell hates vibration and dust.”

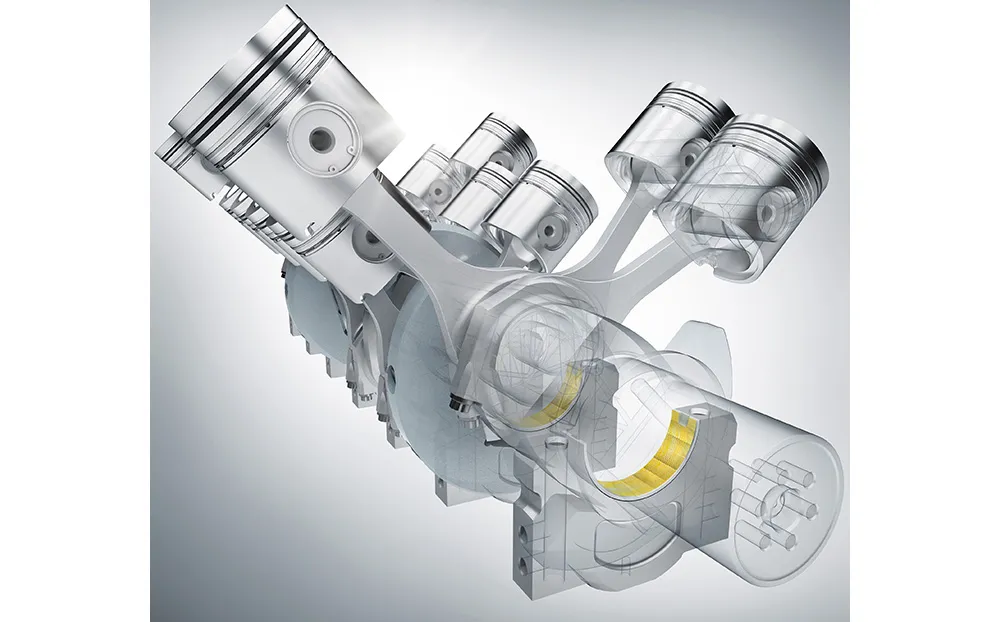

Power to the wheels comes from three electric motors mounted in each of the three axles, which means the truck does away with the need for a torque converter and driveshafts. Heavily protected cables run through the articulation joint, instead of a conventional driveline. He said that the electric drive offers some benefits too as the motor controls allow the machine to switch between 6WD, 4WD and 2WD, depending on the running conditions. Electro-magnetic braking is also available and the drive system can be regenerative on downhill slopes, charging the 50kW battery system mounted in a protected location on the rear chassis.

While battery electric trucks may not be feasible due to the weight of the batteries, hybrid machines are certainly more practical and as the fuel-cell truck shows, using direct electric drive to the axles means the complicated mechanical driveline can be eliminated. A hybrid truck using alternative, low carbon fuels with an electric driveline could well be the fruit of this innovative ADT research project.